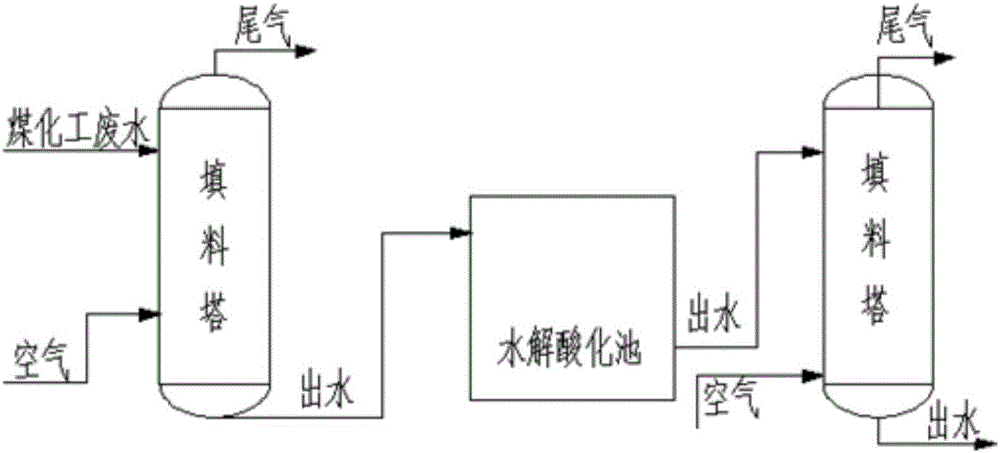

Coal chemical industry wastewater pretreatment method with combination of hydrolytic acidification and ammonia-nitrogen desorption

A technology for blowing off coal chemical wastewater and ammonia nitrogen, applied in mining wastewater treatment, biological water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems of high organic nitrogen content and low ammonia nitrogen content, and achieve low treatment cost , good total nitrogen pre-removal, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

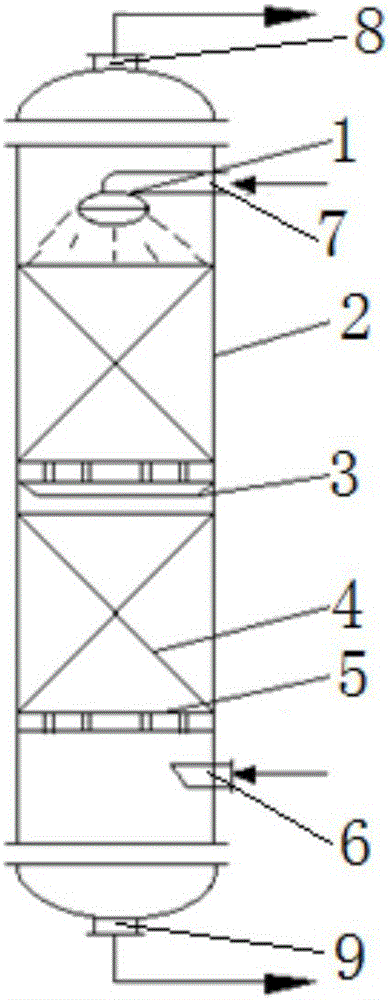

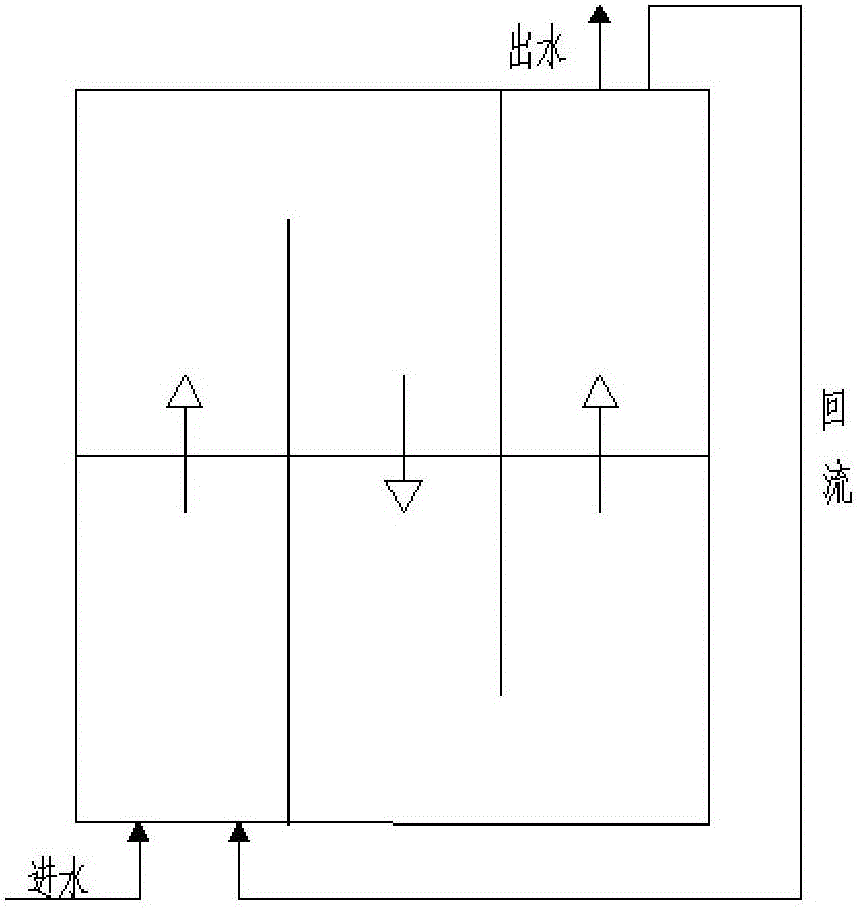

Method used

Image

Examples

Embodiment 1

[0032] In this example, a certain coal-gas wastewater in Xinjiang is treated as the treatment object. The COD concentration in the treated wastewater is 17061±1000mg / L, the TN concentration is 6992±100mg / L, the ammonia nitrogen concentration is 3135±100mg / L, the organic nitrogen concentration is 3857±100mg / L, the C / N is 2.44, and the pH value is 8.82.

[0033] (1) One-stage stripping: control the gas-liquid ratio to 1000-1500 and use air as the carrier to blow off. The tail gas after stripping is absorbed by acid and alkali in multiple stages and then discharged. The removal of ammonia nitrogen changed with time, and the results are shown in Table 1.

[0034] Table 1 Ammonia Nitrogen Removal Situation after Primary Stripping

[0035] time (h)

[0036] It can be seen from Table 1 that the gas-liquid ratio of the first-stage stripping control is 1000-1500. After 5 hours of stripping, the concentration of ammonia nitrogen drops to 288±50mg / L, and the removal rate reache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com