Polystyrene pre-curing system

A technology of polystyrene and pre-curing, which is applied in chemical instruments and methods, solid separation, filtration and screening, etc. It can solve problems such as uneven spraying, difficult removal of miscellaneous materials, and easy flying, so as to increase the degree of automation and improve Production efficiency and the effect of prolonging suspension time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

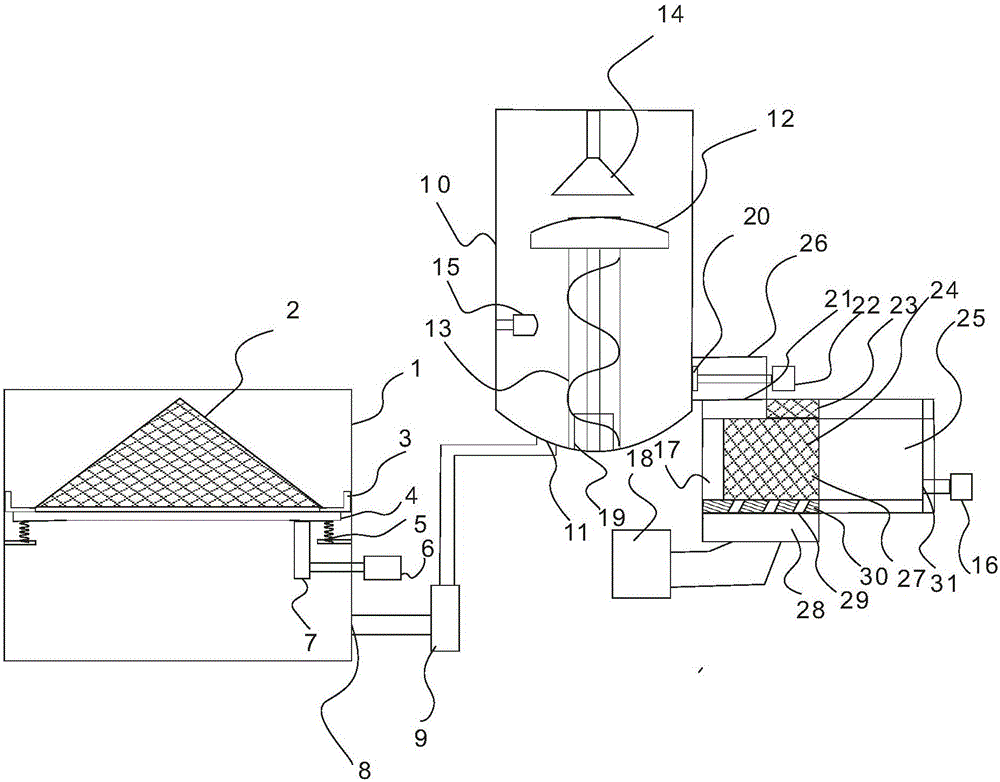

[0011] As shown in the figure, a polystyrene pre-curing system includes a silo vibrating screening device, a stirring tank 10 provided with a feed inlet 11 and a discharge port 20, an automatic spraying device and a pre-curing bin. The bin vibration screening device includes a circular bin body 1, a vibrating frame 4 and a screening frame. Both sides of the vibrating frame are connected to the bin body 1 through vibrating springs 5. Above, the bottom of the vibrating frame 4 is connected to the eccentric wheel 7, and the eccentric wheel 7 is driven by the motor 6. The screening frame includes a conical screen 2 and an annular receiving material arranged at the lower edge of the conical screen 2. Groove 3, the annular mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com