Insecticide composition containing cyclaniliprole and cycloxaprid

A technology of cyclotraniliprole and insecticidal composition, which is applied in the field of insecticidal composition containing cyclotraniliprole and cyclopyrid, which can solve the problem of excessive pesticide residues, polluting the environment, the cost of pesticides for farmers, and unfavorable agricultural sustainable development To reduce pollution, reduce the use of pesticides, and delay pest resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

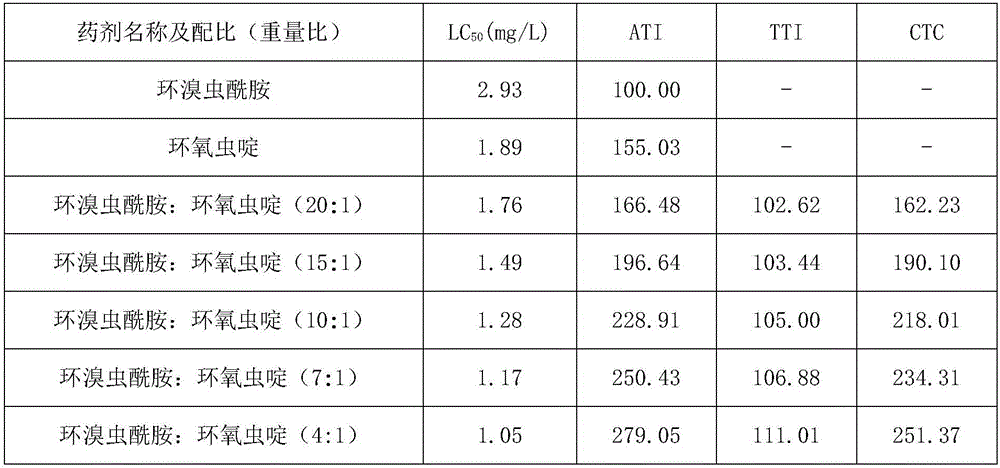

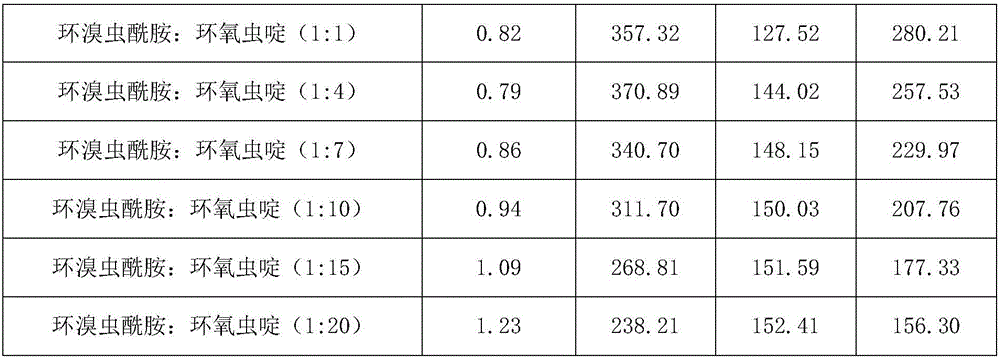

Method used

Image

Examples

Embodiment 1

[0017] Example 1: 24% Cyclotraniliprole · Cyclopyrid Microcapsule Suspension Concentrate

[0018] The following materials are all percentages by weight: Cyclotraniliprole 12%, Cyclopyrid 12%, Melamine-formaldehyde resin (capsule wall material) 8%, Dimethyl carbonate (solvent) 10%, Castor oil polyoxyethylene ether ( Emulsifier) 5%, maleic acid-acrylic acid copolymer sodium salt (dispersant) 3%, citric acid (pH regulator) 1.5%, and deionized water to make up to 100%. Mix the above-mentioned active ingredient, capsule wall material, and solvent to dissolve into a uniform oil phase, add the oil phase to the aqueous phase solution containing emulsifier, dispersant, and pH regulator, and make up the balance with deionized water. After cutting, dispersing and solidifying, 24% Cyclotraniliprole · Cyclofenac Microcapsule Suspension Concentrate can be prepared.

[0019] This embodiment is used for preventing and treating rice planthopper: 24% cyclotraniliprole · cyclopyrid microcapsu...

Embodiment 2

[0020] Example 2: 20% Cyclotraniliprole · Cyclopyrid Suspending Concentrate

[0021] The following substances are all percentages by weight: Cyclotraniliprole 10%, Cyclopyrid 10%, Sodium Lauryl Sulfate (wetting agent) 2%, Phenylphenol Polyoxyethylene Ether Phosphate (dispersant) 5% %, ethylene glycol (antifreeze) 3%, xanthan gum (thickener) 1.5%, sodium sorbitol (preservative) 0.2%, epoxy soybean oil (defoamer) 0.2%, triethanolamine (pH adjustment agent) 0.2%, vegetable oil (synergist) 2%, and deionized water to make up 100%. The above-mentioned active ingredients, wetting agent, dispersant, antifreeze agent, thickener, preservative, defoamer, pH regulator, synergist and deionized water are dispersed by high-speed shearing, sanded in a sand mill, and ground in a sand mill. The highly dispersed and stable suspension system formed in the water medium can be used to prepare 20% Cyclotraniliprole · Cyclopyrid Suspending Concentrate.

[0022] This embodiment is used for preventin...

Embodiment 3

[0023] Example 3: 35% Cyclotraniliprole · Cyclopyrid Water Emulsion

[0024] The following substances are all percentages by weight: cyclanthraniliprole 30%, cyclopyridam 5%, methyl palm oleate (solvent) 15%, hydroxyl-terminated polyoxyethylene polyoxypropylene ether (emulsifier) 10%, glycerin fat Acetate polyoxyethylene ether (dispersant) 5%, epichlorohydrin (stabilizer) 3%, glycerol (antifreeze) 2%, organosiloxane (defoamer) 0.2%, sodium benzoate (corrosion agent) 0.2%, urea (density modifier) 1.5%, hydroxymethylcellulose (thickener) 0.5%, deionized water to make up 100%. Mix the above active ingredients, solvents, emulsifiers, dispersants and stabilizers to form an oil phase, and dissolve antifreeze, antifoaming agents, preservatives, density regulators and thickeners in deionized water to form a water phase. Slowly add the oil phase into the water phase, and continue shearing for about 30 minutes to obtain a 35% cyclotraniliprole-epoxypyrid aqueous emulsion.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com