A thermal fatigue test device under simulated gas environment

A test device and thermal fatigue technology, which is applied in the field of aero-engines, can solve problems that cannot be applied to engineering applications, and achieve the effects of compact structure, energy-saving transportation, and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

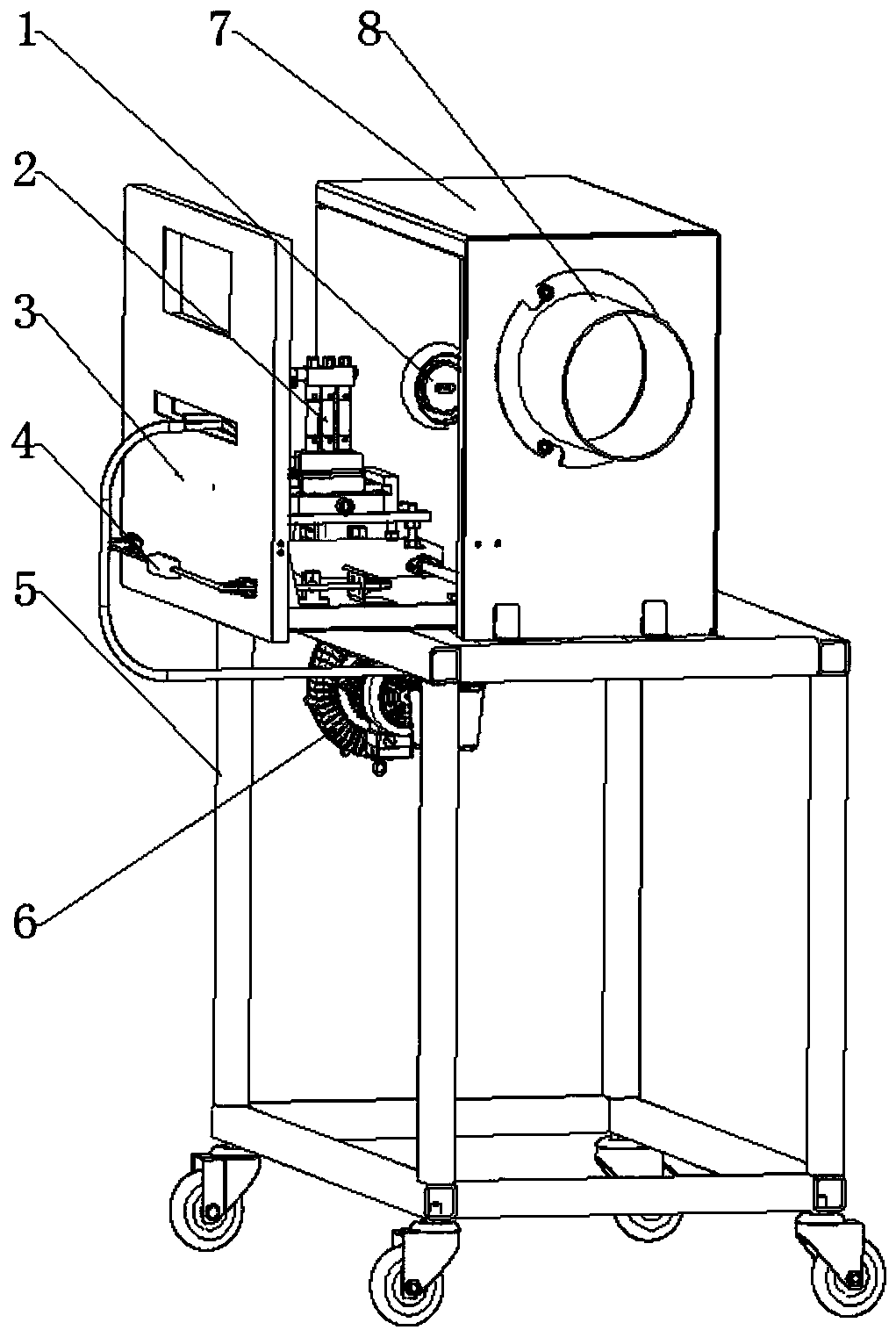

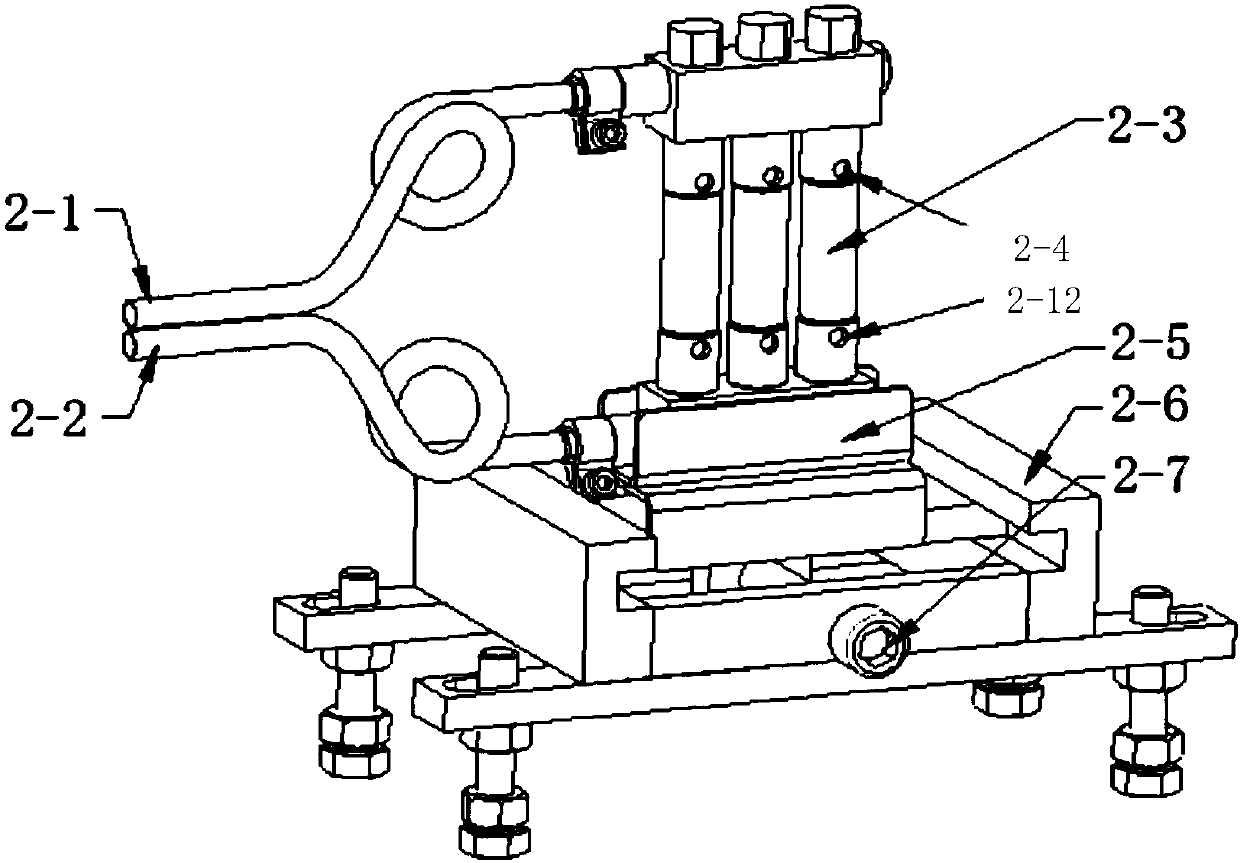

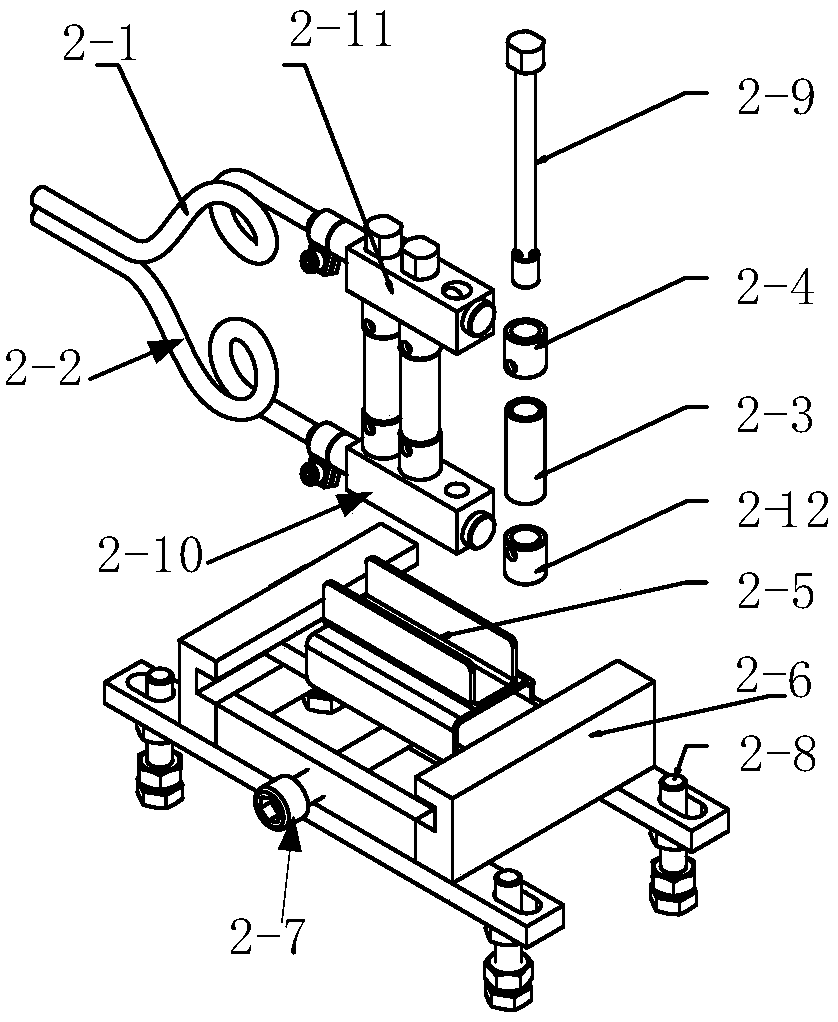

[0024] The invention provides a thermal fatigue test device under simulated gas environment, such as figure 1 As shown, the test device includes a burner 1 , a fixture 2 , a fixture support table 3 , a movable platform 12 , a support frame 5 , a blower 6 , a furnace body 7 and an exhaust device 8 . The bottom of the support frame 5 is equipped with universal casters, which is convenient for transportation and movement. A furnace body 7 is fixedly arranged on the support frame 5, a burner 1 and an exhaust device 8 are fixedly arranged on the left and right sides of the furnace body 7, and the high-temperature gas produced by the burner 1 heats the test piece 2-3 Then it is discharged through the exhaust device 8. Preferably, the burner 1 and the exhaust device 8 are arranged coaxially. The support frame 5 at the bottom of the body of furnace 7 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com