Steam generating system used for medium-high-voltage and high-power electrode

A generation system, high-power technology, applied in the direction of steam generation, steam boilers, electrode boilers, etc., can solve the problems of high maximum power, low heat storage temperature, restricting the total power of boilers, etc., so as to reduce the cost of power transmission and transformation, reduce power The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

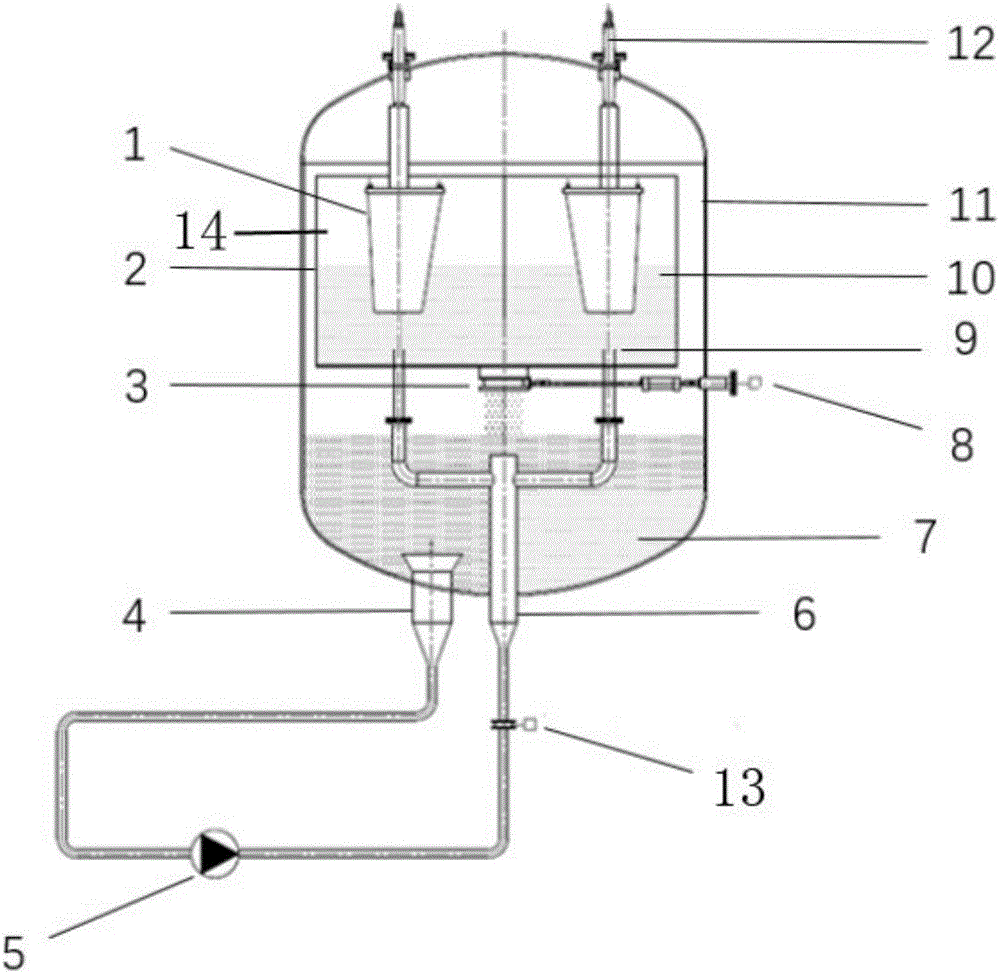

[0023] The principle of electrode technology is that the electrolyte solution has conductivity. When the current passes through the electrolyte solution, it will electrolyze to generate heat, thereby heating water to generate steam. Because the electric energy is directly converted into heat energy, there is no intermediate process, and there is almost no energy loss, so the electrode heating has a high heat conversion efficiency, which can usually reach more than 99.8%.

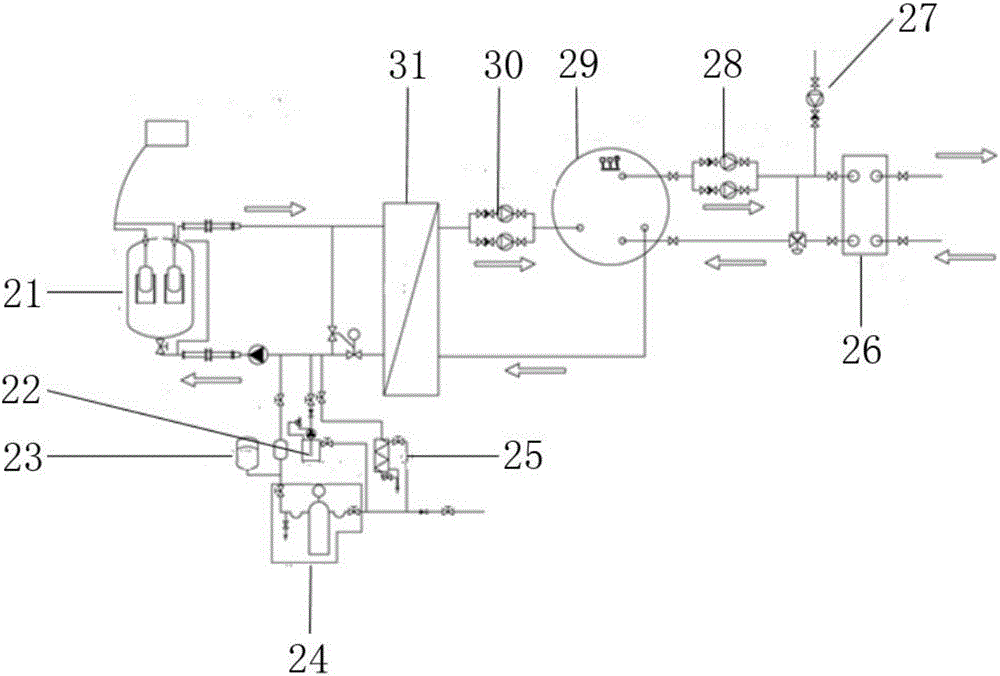

[0024] Such as figure 1 As shown, the steam generation system for medium and high-voltage electric high-power electrodes includes an electrode boiler 21, a dosing device 22, an expansion tank 23, a water treatment device 24, a sampler 25, a heat transfer heat exchanger 26, a water supply device 27, and a water discharge device 27. heat circulation pump 28 , heat storage container 29 , heat storage circulation pump 30 and steam heat exchanger 31 .

[0025] The pure water produced by the water treatment devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com