Super-concentrated washing piece and preparation method thereof

A production method and technology of laundry tablets, which are applied to chemical instruments and methods, detergent powder/flake/sheet, detergent materials, etc., can solve the problems of easy waste, laundry detergent is not easy to carry, and the content of active substances in decontamination components is not high. problem, to achieve the effect of enhancing the stimulating effect and improving the decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

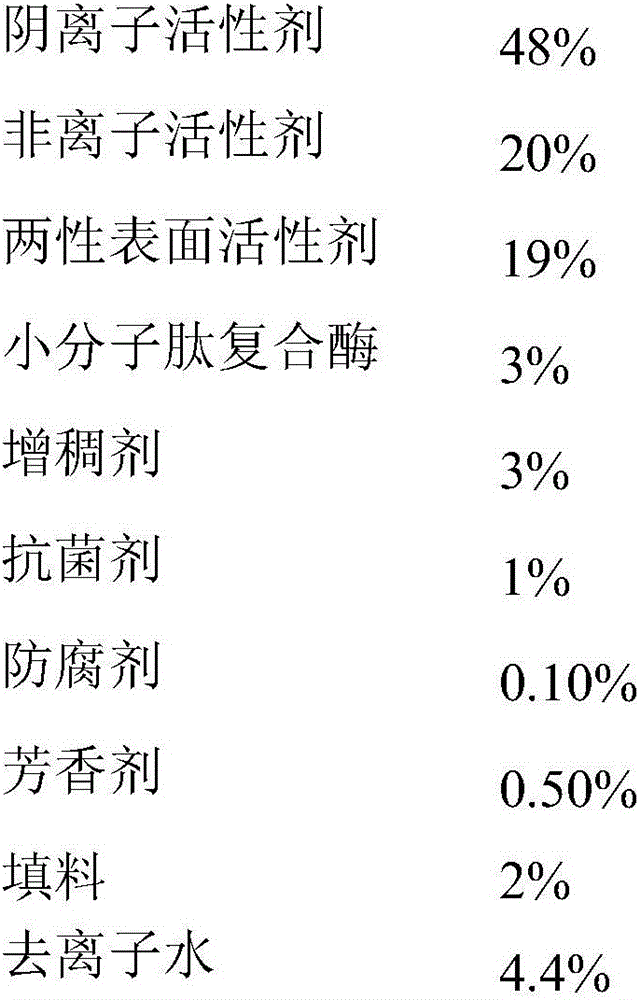

[0030] A kind of super-concentrated laundry tablet, this super-concentrated laundry tablet is made by following method;

[0031] Step S001, take 48 grams of anionic active agent sodium lauryl sulfate (K12 for short), 20 grams of nonionic fatty alcohol polyoxyethylene ether (abbreviated AEO), amphoteric surfactant dodecyl dimethyl sulfopropyl beet Alkali (CAB) 19 grams, put into preparation container and constantly stir;

[0032] Then take 3 grams of thickener xanthan gum, 1 gram of antibacterial agent nano-silver, 0.1 gram of preservative Cathone (CIT / MIT for short), 2 grams of filler corn starch, 0.5 gram of fragrance essence, and appropriate amount of deionized water. Put it into the preparation container, stir continuously and fully mix the components to obtain the raw material for making liquid ultra-concentrated laundry tablets;

[0033] Step S002, pressing the raw materials for making liquid super-concentrated laundry tablets prepared in the above step S001 into a sheet...

Embodiment 2

[0040] A kind of super-concentrated laundry tablet, this super-concentrated laundry tablet is made by following method;

[0041] Step S001, 8 grams of anionic active agent sodium lauryl alcohol polyoxyethylene ether sulfate (abbreviated as AES), 6 grams of alpha-olefin sulfonate (abbreviated as AOS), 6 grams of sodium hexadecyl sulfonate (abbreviated as SAS) 14 grams are mixed, so that the composition gross mass is 28 grams, and the mixing ratio is a mixed type anionic active agent of 4:3:7;

[0042] Mix 20 grams of non-ionic active agent alkylphenol polyoxyethylene ether (abbreviated as APEO) and 20 grams of fatty alcohol polyoxyethylene ether (abbreviated as AEO) to form a mixture with a total mass of 40 grams and a mixing ratio of 10:11. Type nonionic active agent;

[0043] Mix 6 grams of amphoteric surfactant cocyl imidazoline (abbreviated as CAMA) and 8 grams of cocamidopropyl dimethyl betaine (abbreviated as CAB), so as to form a total mass of 14 grams and a mixing rati...

Embodiment 3

[0055] A kind of super-concentrated laundry tablet, this super-concentrated laundry tablet is made by following method;

[0056] Step S001, mixing 21 grams of anionic active agent sodium alkylbenzenesulfonate (abbreviated as LAS) and 35 grams of sodium lauryl sulfate (abbreviated as K12) to form a compound with a total mass of 56 grams and a mixing ratio of 3:5. Mixed anionic active agent;

[0057] The ethylene oxide adduct 6 grams, alkyl glucoside 14 grams of 4 grams of nonionic active agent coconut oil fatty acid monoethanolamide (CMEA for short), polypropylene glycol, thus form gross mass and be 24 grams, mixing ratio is 2: 3:7 mixed non-ionic active agent;

[0058] Put the above mixed anionic active agent and nonionic active agent into the preparation container and keep stirring, then take 7 grams of amphoteric surfactant decanyl dimethyl hydroxypropyl sulfobetaine, thickener polyethylene 2.5 grams of the mixture of diol-15 and polyvinyl alcohol, 0.5 grams of antibacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com