Novel coal water slurry preparation method and coal water slurry prepared by using same

A technology of coal-water slurry and slurry, which is applied in the field of coal chemical industry to achieve the effects of reducing production costs, improving gasification efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

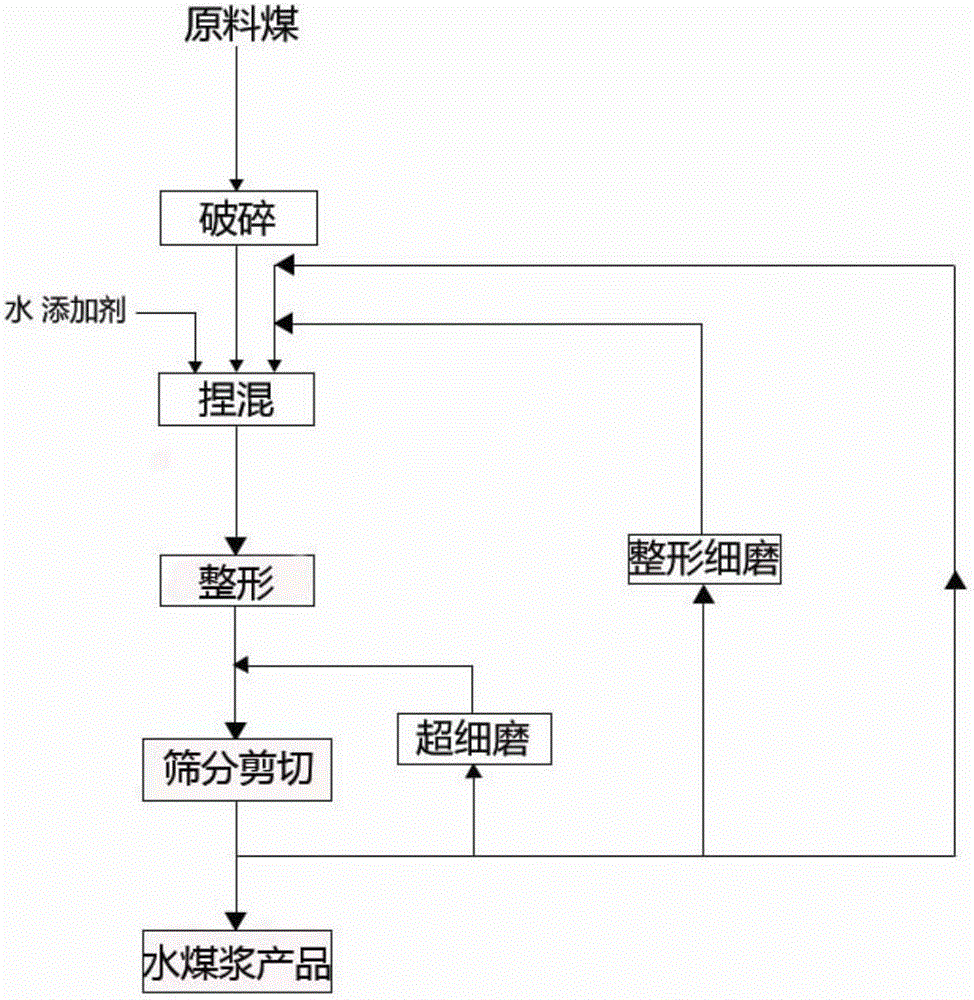

Method used

Image

Examples

Embodiment 1

[0062] A method for preparing fuel coal-water slurry from Shenfu coal. Shenfu coal is a common low-rank coal in Shaanxi area. The analytical water is 5.9%, the total water is 12.8%, and the ash content is 19.9%.

[0063] The method comprises the steps of:

[0064] (1) crushing Shenfu coal to coal powder with a particle size less than 13mm to obtain the first slurry;

[0065] (2) mixing the first slurry with water and additives according to the mass ratio of 92:8:0.3 and kneading to obtain the second slurry with a concentration of 80.8wt%;

[0066] (3) Reshaping the second slurry, as a fuel coal-water slurry, the maximum particle size is less than 0.5mm, and the material less than 75 μm accounts for more than 75% of the total material, and the third slurry having a concentration of 68.2wt% is obtained;

[0067] (4) After the third slurry is removed by an 8-mesh sieve and sheared under a shear force of 110r / s, the fourth slurry having a concentration of 65.5wt% is obtained;

...

Embodiment 2

[0071] A method for preparing gasified coal-water slurry from lignite, which is a common low-rank coal in the Hailaer area of Inner Mongolia, has an analytical water content of 12.5%, a total water content of 25%, and an ash content of 19.9%.

[0072] The method comprises the steps of:

[0073] (1) crushing lignite to pulverized coal with a particle size less than 13 mm to obtain the first slurry;

[0074] (2) mixing the first slurry with water and additives according to the mass ratio of 95:5:0.3 and kneading to obtain the second slurry with a concentration of 70.8wt%;

[0075] (3) Reshaping the second slurry, as a gasified coal-water slurry, the maximum particle size is 2.4mm, and the material less than 75 μm accounts for more than 40% of the total material, and the third slurry having a concentration of 59.8wt% is obtained;

[0076] (4) After the third slurry is removed by a 14-mesh sieve and sheared under a shear force of 80r / s, the fourth slurry with a concentration of...

Embodiment 3

[0080] A method for preparing gasified coal-water slurry from Xinjiang Hongshan coal. Xinjiang Hongshan coal is a common low-rank coal in the Zhungeer area of Xinjiang. The analyzed water is 9.7%, the total water is 18.5%, and the ash content is 12.9%. The particle size is less than 50mm.

[0081] The method comprises the steps of:

[0082] (1) crushing Xinjiang coal to coal powder with a particle size less than 13mm to obtain the first slurry;

[0083] (2) kneading after mixing the first slurry with water and additives according to the mass ratio of 91:9:0.3 to obtain the second slurry with a concentration of 74.3wt%;

[0084] (3) Reshaping the second slurry as a gasified coal-water slurry with a maximum particle size of 2.4mm, and materials less than 75 μm accounted for more than 40% of the total material to obtain a third slurry with a concentration of 63.5wt%;

[0085] (4) After the third slurry is removed by a 14-mesh sieve and sheared under a shear force of 90r / s, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com