UV outdoor screen printing ink and preparation technology thereof

A screen printing ink and outdoor technology, which is applied in the chemical industry, can solve the problems of coating space density cracking, high cost, and poor printing suitability of the protective layer, etc., and achieve the effects of small impact on system performance, long outdoor service life, and reduced ink cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

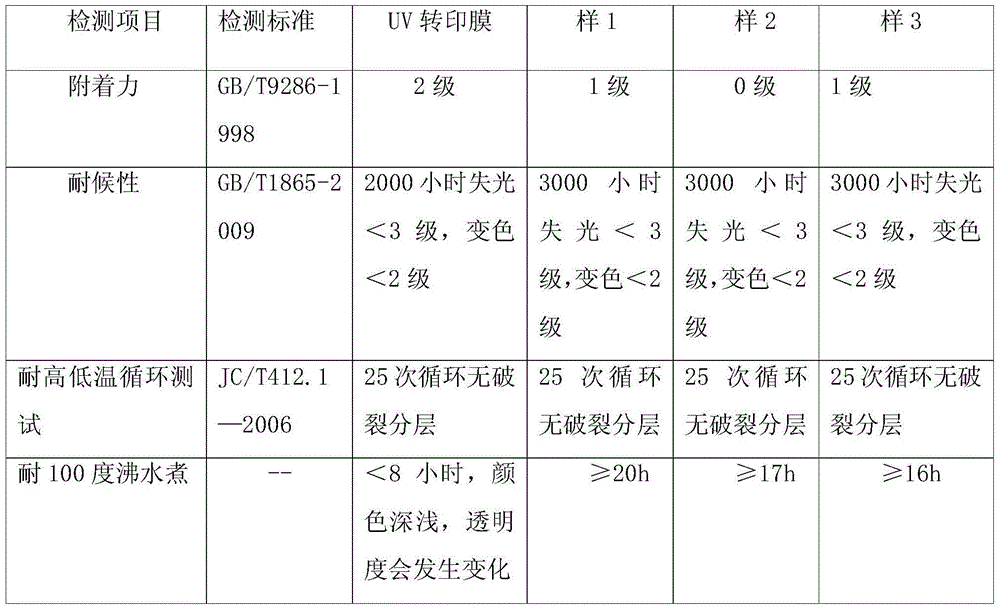

Examples

Embodiment 1

[0033] Example 1, the present invention includes the following components and raw materials in mass ratio: 25 parts of oligomer, 25 parts of diluent, 0.2 part of dispersant, 0.05 part of defoamer, 3 parts of initiator, 10 parts of pigment, 15 parts of filler , 1 part of solvent, 2 parts of anti-settling agent. In this embodiment, the oligomer is made by mixing aliphatic epoxy acrylate resin and aliphatic urethane acrylate resin, wherein the aliphatic epoxy acrylate resin is MR-2290, the aliphatic urethane acrylate resin is T95, and other Aliphatic epoxy acrylate resin and aliphatic urethane acrylate resin in the embodiment can also be replaced by other types of resins that can achieve the same effect. This system not only makes the ink coating itself possess excellent strength, and, due to the aliphatic modified The strong resin itself has low double bond content, and the high double bond conversion rate after reaction makes the ink coating have good stability in outdoor envir...

Embodiment 2

[0034] Example 2, the present invention includes the following components and raw materials in mass ratio: 30 parts of oligomers, 30 parts of diluents, 1.5 parts of dispersants, 0.2 parts of defoamers, 5 parts of initiators, 15 parts of pigments, and 20 parts of fillers , 4 parts of solvent, 6 parts of anti-settling agent.

[0035] In this embodiment, the oligomer is formed by mixing aliphatic epoxy acrylate resin and aliphatic urethane acrylate resin, wherein the aliphatic epoxy acrylate resin is 6109D, and the aliphatic urethane acrylate resin is T100. Other examples The medium aliphatic epoxy acrylate resin and aliphatic urethane acrylate resin can also be replaced by other types of resins that can achieve the same effect. This system not only makes the ink coating itself have excellent strength, but also, due to the aliphatic modified The double bond content of the resin itself is low, and the high double bond conversion rate after the reaction makes the ink coating have g...

Embodiment 3

[0036]Embodiment 3, the present invention comprises the following components and the raw material of mass ratio: 27 parts of oligomers, 27 parts of diluents, 0.8 parts of dispersants, 0.1 parts of defoamers, 4 parts of initiators, 13 parts of pigments, 17 parts of fillers , 2 parts of solvent, 4 parts of anti-settling agent. In this example, the oligomer is made by mixing aliphatic epoxy acrylate resin and aliphatic urethane acrylate resin, wherein the aliphatic epoxy acrylate resin is MR-2290, the aliphatic urethane acrylate resin is T100, and other Aliphatic epoxy acrylate resin and aliphatic urethane acrylate resin in the embodiment can also be replaced by other types of resins that can achieve the same effect. This system not only makes the ink coating itself possess excellent strength, and, due to the aliphatic modified The strong resin itself has low double bond content, and the high double bond conversion rate after reaction makes the ink coating have good stability in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com