Air sealing body

A technology of air sealing body and sealing body, which is applied in the direction of closing devices, containers, packaging items, etc., can solve the problems of difficult opening and inflation at the opening point, inaccurate alignment, and unsmoothness, etc., and achieve fast, stable and effective air locking performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

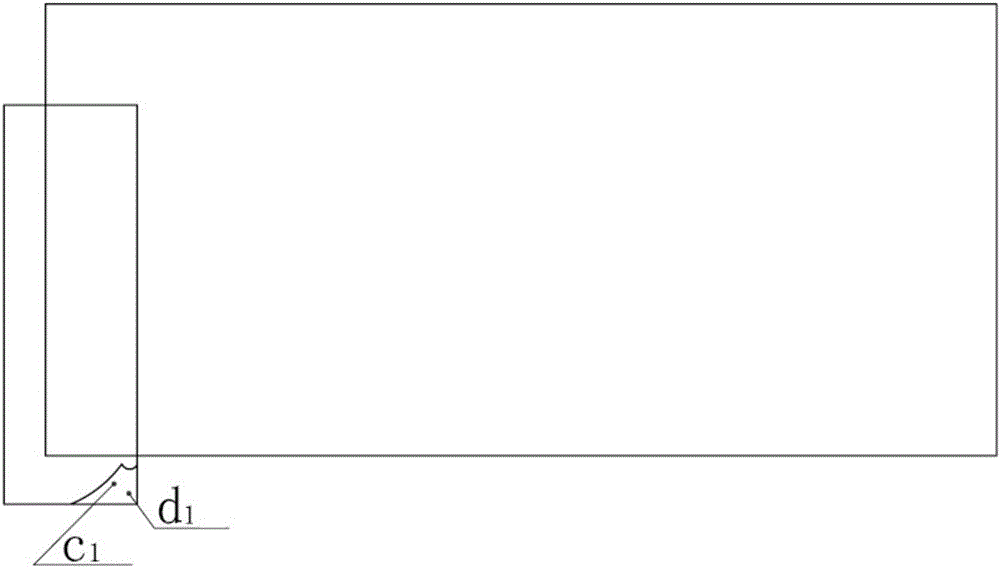

[0039] Embodiment 1: In a specific embodiment, there are two inner films that are automatically close to each other so as to block the air path. Add thermoplastic elastomer POE to the surface (c1 surface and d1 surface), and thermoplastic elastomer cannot be added to the outer layer, otherwise it will be difficult to process in the subsequent process.

[0040] After the inner film added with thermoplastic elastomer is heat-sealed and processed, the gas enters the airbag through the channel and can be automatically closed and closed to block the backflow of air. The two inner films of the original patent are extruded by the increase of internal air pressure. The membrane makes it tight and prevents backflow of air.

Embodiment 2

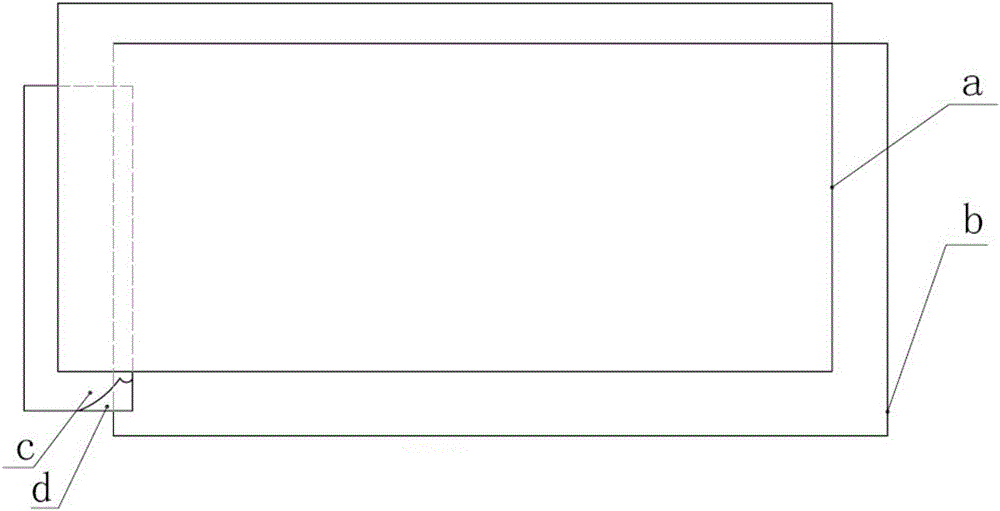

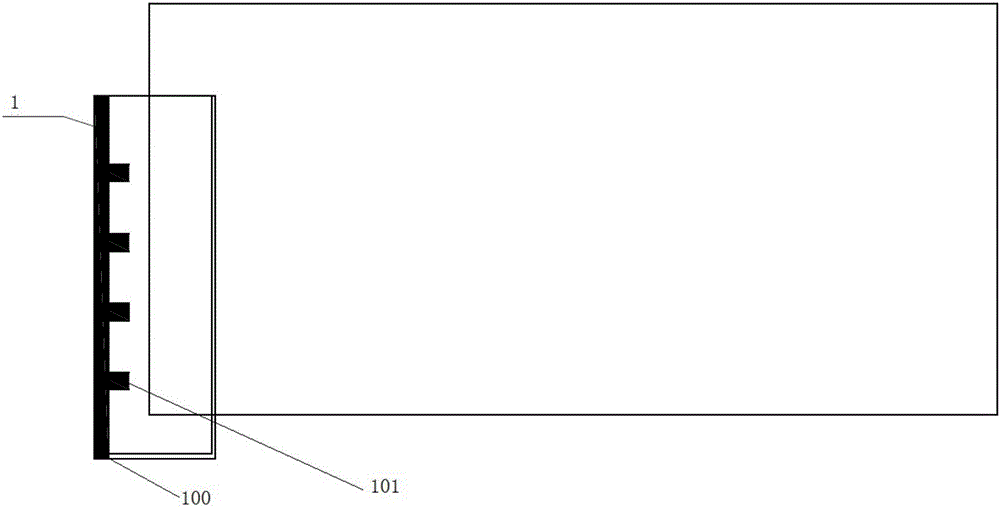

[0041] Embodiment 2: An air-tight body, comprising two outer membranes (a, b), two inner membranes (c, d), and thermoplastic elastomer POE added to the opposite side (c1, d1) of the two inner membranes; No thermoplastic elastomer POE is added to the other side of the sheet that is not in contact with the inner film. On the top of one of the opposite surfaces of the two inner films, a continuous strip or line of heat-resistant material is coated along the width direction to form the first heat-resistant material zone; the second heat-resistant material zone Communicating with the first heat-resistant material area, the first heat-resistant material area is coated with a plurality of second heat-resistant material areas at intervals as air intake channels; the first heat-resistant material area is not parallel to the second heat-resistant material area.

Embodiment 3

[0042] Embodiment 3: An air-tight body, comprising two outer membranes (a, b), two inner membranes (c, d), and thermoplastic elastomer POE added to the opposite side (c1, d1) of the two inner membranes; No thermoplastic elastomer POE is added to the other side of the sheet that is not in contact with the inner film. On the top of one of the opposite surfaces of the two inner films, a continuous strip or line of heat-resistant material is coated along the width direction to form a heat-resistant line; the second heat-resistant material area communicates with the heat-resistant line A plurality of second heat-resistant material areas are coated at intervals below the heat-resistant line as air intake passages; the first heat-resistant material area is not parallel to the heat-resistant line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com