Miniature all-electric injection molding machine injection guide structure

A guiding structure, all-electric technology, applied in the field of mechanical transmission mechanism and guiding device, can solve the problems of insufficient precision and configuration, unstable guiding, etc., to reduce abnormal wear, improve the accuracy of plastic parts, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

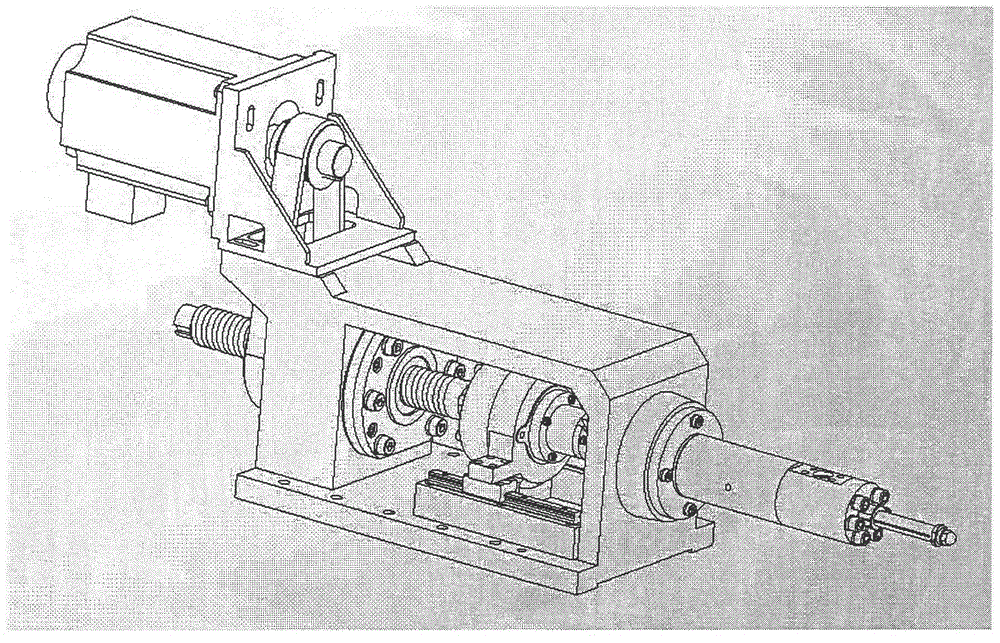

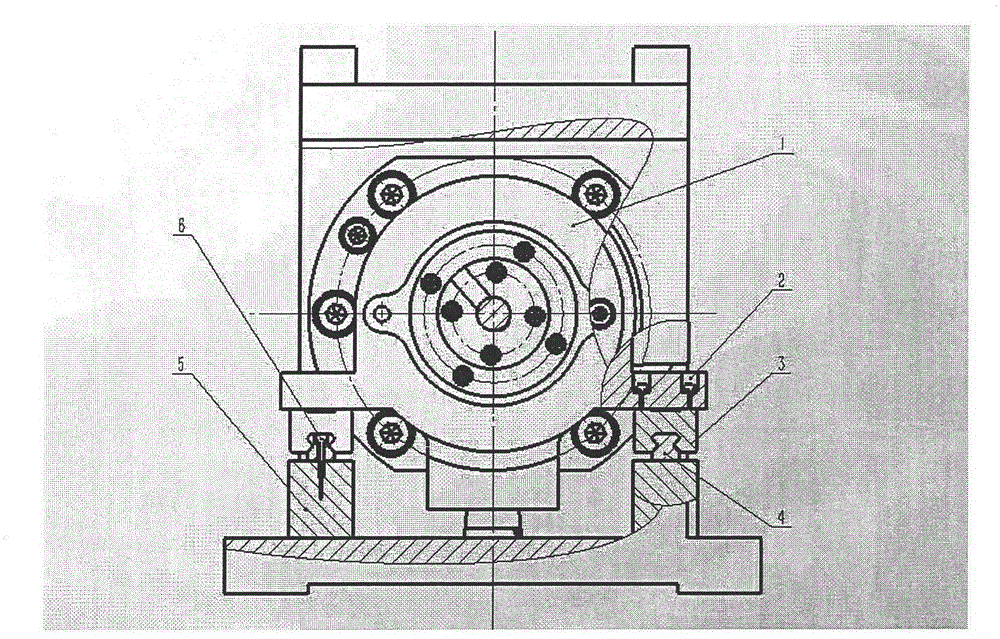

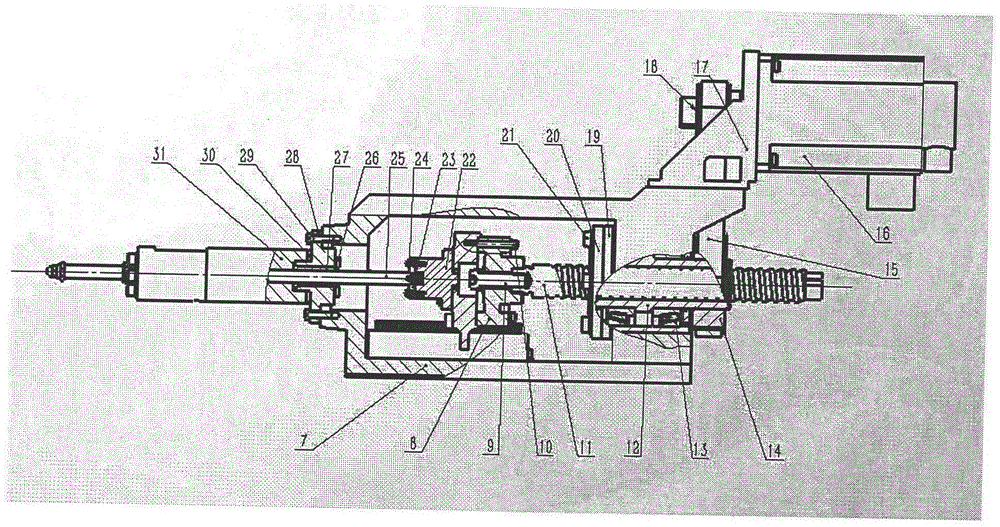

[0013] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the injection guide device of the injection device in the injection unit of a miniature all-electric injection molding machine realizes the precise guidance of the injection screw and the injection rod through the guide rail and the injection guide plate. It includes the injection guide plate (1), the slider Bolts and washers (2), guide rail sliders (3), guide rails (4), guide rail backing plates (5), backing plate bolts and washers (6), injection brackets (7), tension pressure sensors (8), locking Bolt and washer (9), sensor bolt and washer (10), injection screw (11), injection screw nut (12), screw nut bearing (13), motor pulley (14), injection timing belt (15 ), injection motor (16), motor bracket (17), screw pulley (18), screw bearing housing (19), bearing housing flange (20), bearing housing bolts and washers (21), shooter housing (22), shot rod snap (23), snap bolt and washer (24), injection rod (25), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com