Preparation method for supported catalyst for catalyzing combustion of VOCs (Volatile Organic Compounds)

A supported catalyst, catalytic combustion technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as hindering application and macromolecular diffusion limitations, and achieve reduced dosage and good hydrothermal stability. and anti-sulfur performance, improve the effect of catalytic oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for preparing a supported catalyst for catalytic combustion of VOCs in this embodiment, wherein: it consists of a specific surface area ≥ 500m 2 / g, high specific surface area ZSM-5 molecular sieve and metal precursor with specific pore volume ≥0.6mL / g are made; the specific preparation method comprises the following steps:

[0019] 1) Make the specific surface area ≥ 500m 2 / g, the high specific surface area ZSM-5 molecular sieve with a specific pore volume ≥0.6mL / g is dried at 100°C for 2 hours to remove the moisture adsorbed in the high specific surface area ZSM-5 molecular sieve;

[0020] 2) Copper nitrate is mixed with water, stirred and dissolved to obtain a solution, wherein the mass ratio of the copper metal to the ZSM-5 molecular sieve after step 1) pretreatment is 0.01, and the amount of water is after step 1) pretreatment The quality of the ZSM-5 molecular sieve × specific pore volume;

[0021] 3) Stir and mix the solution prepared in step 2) with ...

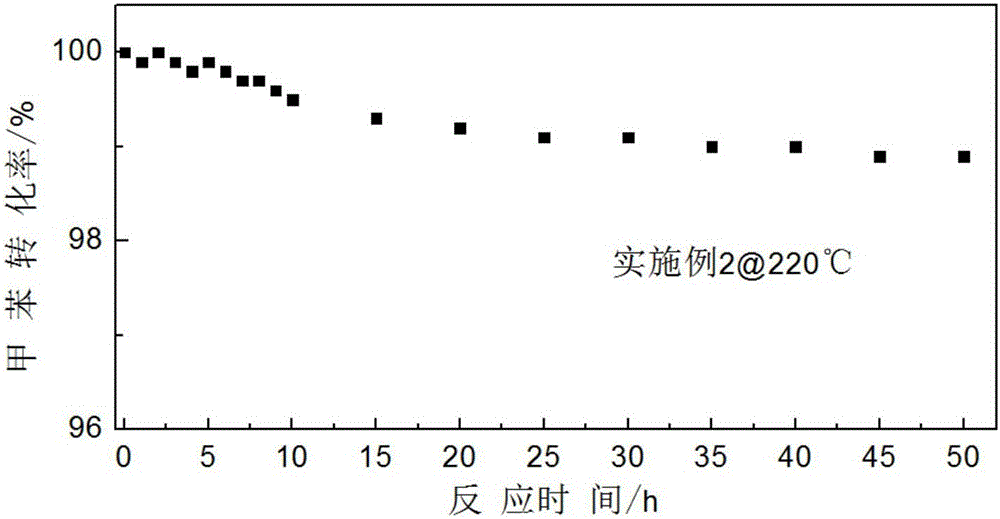

Embodiment 2

[0026] A method for preparing a supported catalyst for catalytic combustion of VOCs in this embodiment, wherein: it consists of a specific surface area ≥ 500m 2 / g, high specific surface area ZSM-5 molecular sieve and metal precursor with specific pore volume ≥0.6mL / g are made; the specific preparation method comprises the following steps:

[0027] 1) Make the specific surface area ≥ 500m 2 / g, the high specific surface area ZSM-5 molecular sieve with a specific pore volume ≥0.6mL / g is dried at 120°C for 4 hours to remove the moisture adsorbed in the high specific surface area ZSM-5 molecular sieve;

[0028] 2) Mix copper nitrate, manganese nitrate and cerium nitrate with water, stir and dissolve to obtain a solution, wherein the mass ratio of copper metal, manganese metal and cerium metal is 2:2:1, copper metal, manganese metal and cerium metal The mass ratio of the total mass and step 1) ZSM-5 molecular sieve after pretreatment is 0.10, and the consumption of water is the q...

Embodiment 3

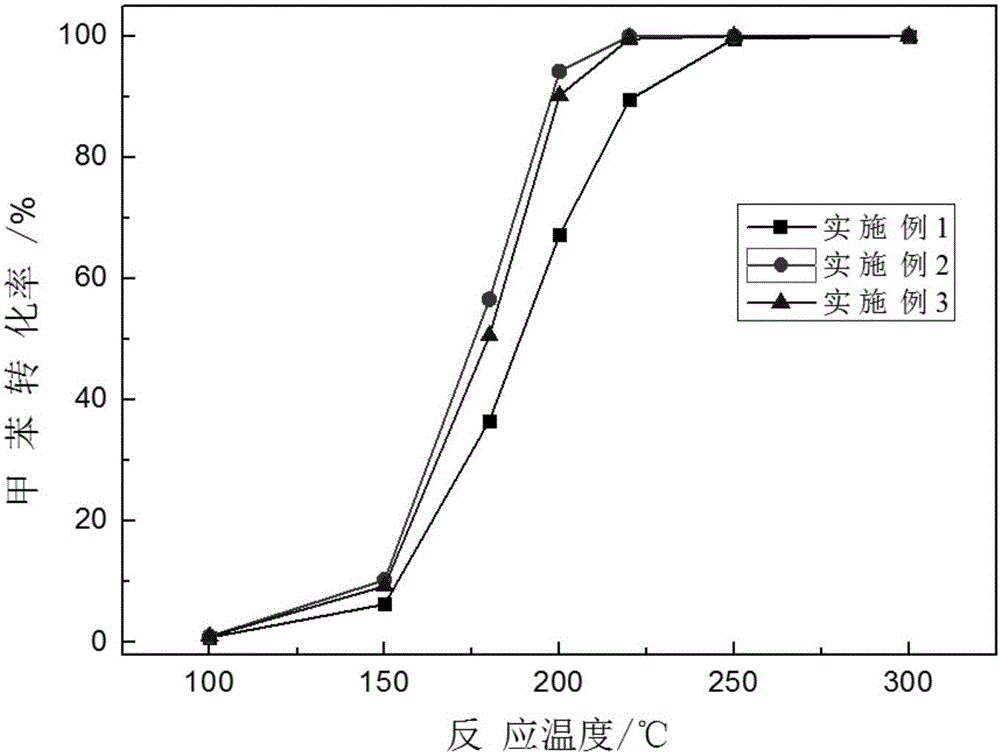

[0035] Such as figure 1 Shown, the experimental result of catalyst catalytic combustion toluene:

[0036] A method for preparing a supported catalyst for catalytic combustion of VOCs in this embodiment, wherein: it consists of a specific surface area ≥ 500m 2 / g, high specific surface area ZSM-5 molecular sieve and metal precursor with specific pore volume ≥0.6mL / g are made; the specific preparation method comprises the following steps:

[0037] 1) Make the specific surface area ≥ 500m 2 / g, the high specific surface area ZSM-5 molecular sieve with a specific pore volume ≥0.6mL / g is dried at 110°C for 3 hours to remove the moisture adsorbed in the high specific surface area ZSM-5 molecular sieve;

[0038] 2) Mix copper nitrate and manganese nitrate with water, stir and dissolve to obtain a solution, wherein the mass ratio of copper metal to manganese metal is 1:1, and the total mass of copper metal and manganese metal is the same as step 1) ZSM after pretreatment The mass r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com