Fuzzy-PI control based active equalization control method for lithium battery

A technology of active equalization and control method, applied in charge equalization circuits, electric vehicles, battery circuit devices, etc., can solve the problems of long equalization time, energy waste, unstable equalization criteria, etc., to avoid damage and reduce energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

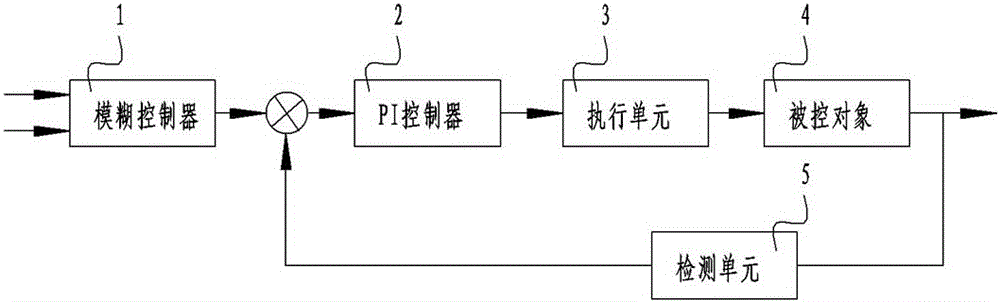

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0014] figure 1 The steps of the lithium battery active equalization control method shown are: 1), detect the charge and discharge current signal of the battery pack in series and the terminal voltage of each single cell, and use the UKF algorithm to estimate the SOC value of each single cell;

[0015] 2), assuming that the battery pack is n cells connected in series, the average SOC of the battery pack SOC difference of each cell ΔSOC is the maximum SOC difference of the single battery in the battery pack;

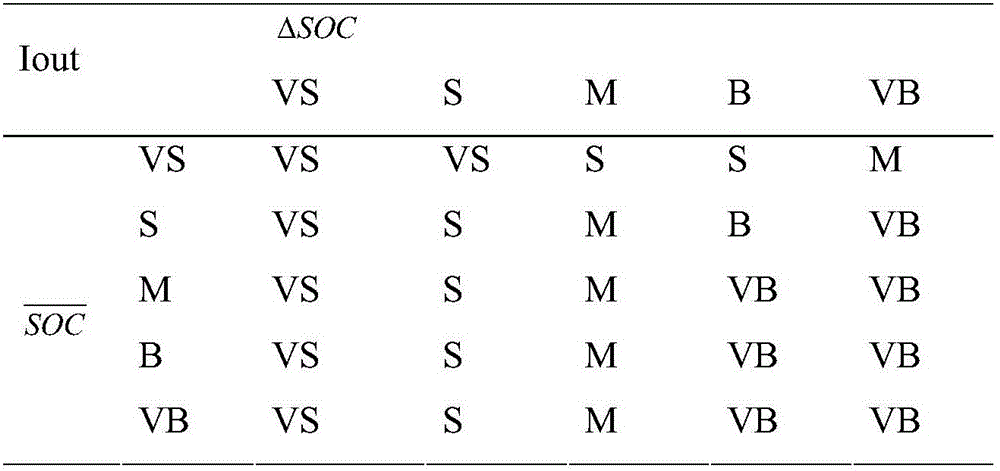

[0016] 3) When ΔSOC ≥ the set value, start the fuzzy controller 1, and the fuzzy controller 1 takes the average and the difference ΔSOC as input, and the mean After performing fuzzy operation with the difference ΔSOC, an accurate equalization current maximum value I can be obtained max The output, through the PI controller 2, the execution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com