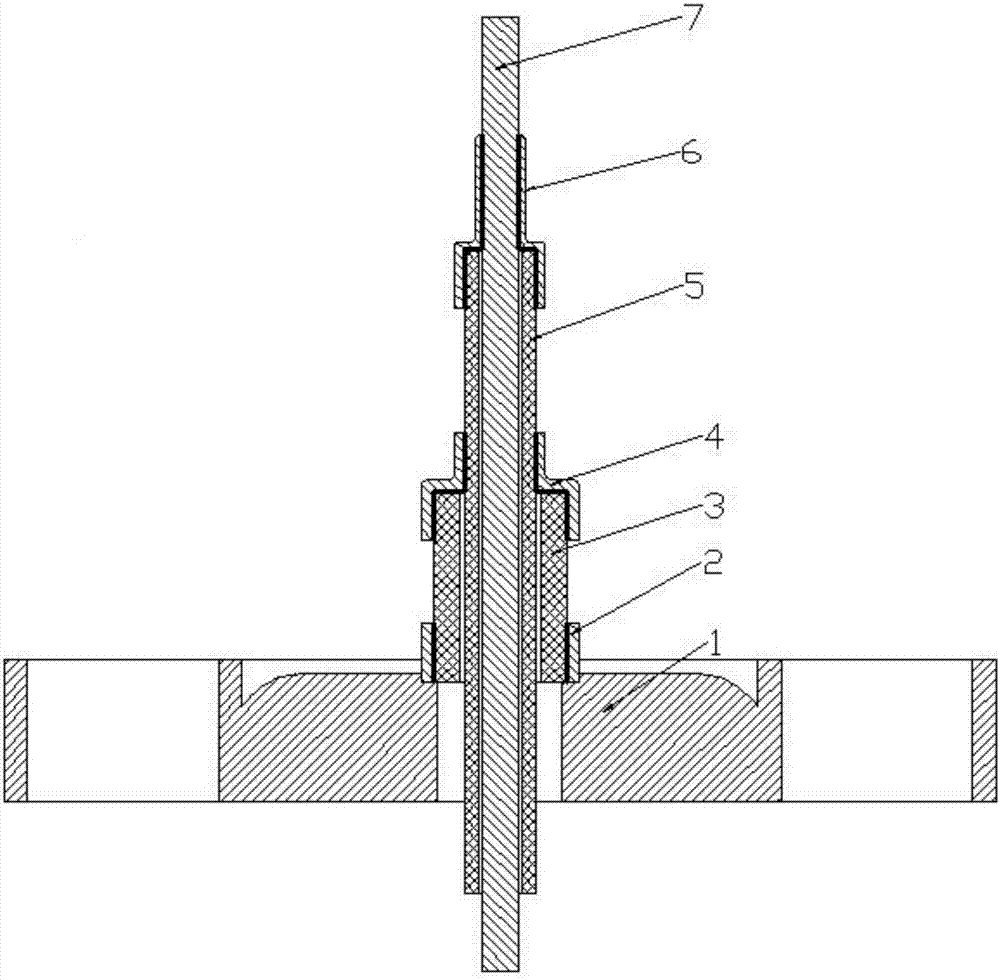

A high-temperature gas-cooled reactor low-voltage control type electrical penetration and its preparation method

A technology of high-temperature gas-cooled reactors and electrical penetrations, applied in the field of nuclear reactors, can solve problems such as leakage current on the surface of insulating materials, interference of control transmission signals, and inapplicability of electrical penetrations, so as to improve the characteristics of radiation resistance and reduce leakage. Conducting current, making up for the effect of short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Put the stainless steel metal flange, kovar sleeve, outer porcelain tube, lower kovar cap, inner porcelain tube, upper kovar cap and kovar guide pin in the cleaning solution at a temperature of 70-80°C Ultrasonic cleaning for 10 minutes; then cleaning with deionized water for 3 to 5 times, then cleaning with absolute ethanol, and finally drying in an oven;

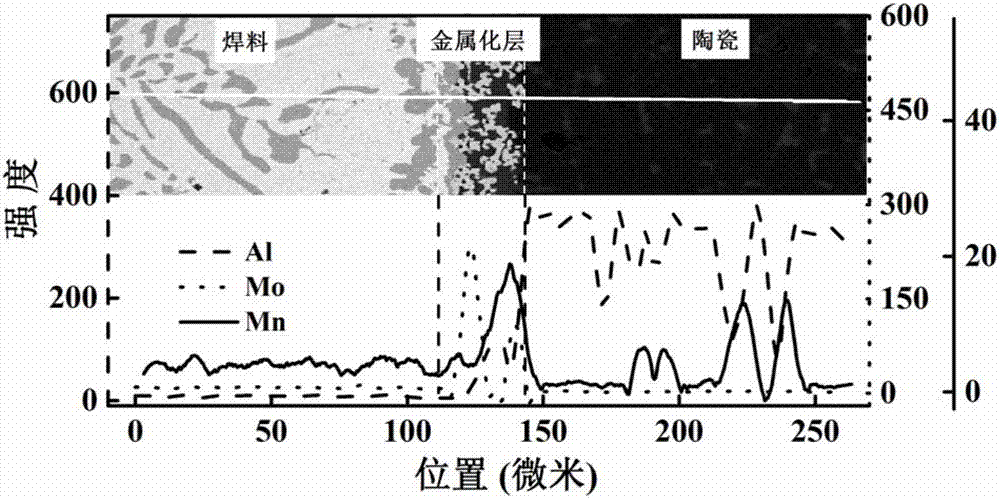

[0026] (2) Prepare metal molybdenum powder, manganese powder and organic activator according to a certain mass ratio (molybdenum powder: organic activator = 2.0: 1; manganese powder: activator = 0.4: 1) to make a paste, and apply it on the outer porcelain The two components of the tube and the inner porcelain tube will be connected with the four components of the lower kovar cap, the upper kovar cap, the kovar guide pin, and the kovar sleeve; the coated outer porcelain tube, inner Porcelain tubes are placed in a hydrogen furnace, heated to 500°C at a rate of 10°C per minute, kept for 5 minutes, then raised to 15...

Embodiment 2

[0032] (1) Put the stainless steel metal flange, kovar sleeve, outer porcelain tube, lower kovar cap, inner porcelain tube, upper kovar cap and kovar guide pin in the cleaning solution at a temperature of 70-80°C Ultrasonic cleaning for 10 minutes; then cleaning with deionized water for 3 to 5 times, then cleaning with absolute ethanol, and finally drying in an oven;

[0033] (2) Prepare metal molybdenum powder, manganese powder and organic activator according to a certain mass ratio (molybdenum powder: organic activator = 2.0: 1; manganese powder: activator = 0.4: 1) to make a paste, and apply it on the outer porcelain The two components of the tube and the inner porcelain tube will be connected with the four components of the lower kovar cap, the upper kovar cap, the kovar guide pin, and the kovar sleeve; the coated outer porcelain tube, inner Place the porcelain tube in a hydrogen furnace, heat up to 500°C at a rate of 10°C per minute, hold for 5 minutes, then heat up to 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com