Etching method of corrosion agent for displaying crystal boundary of quenched and tempered low-alloy chrome molybdenum steel austenite crystal grains

A technology of austenite grains and etchant, which is applied in the field of etching of austenite grain boundary etchant of low alloy chromium molybdenum steel in quenched and tempered state. The effect of short time, convenient operation and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

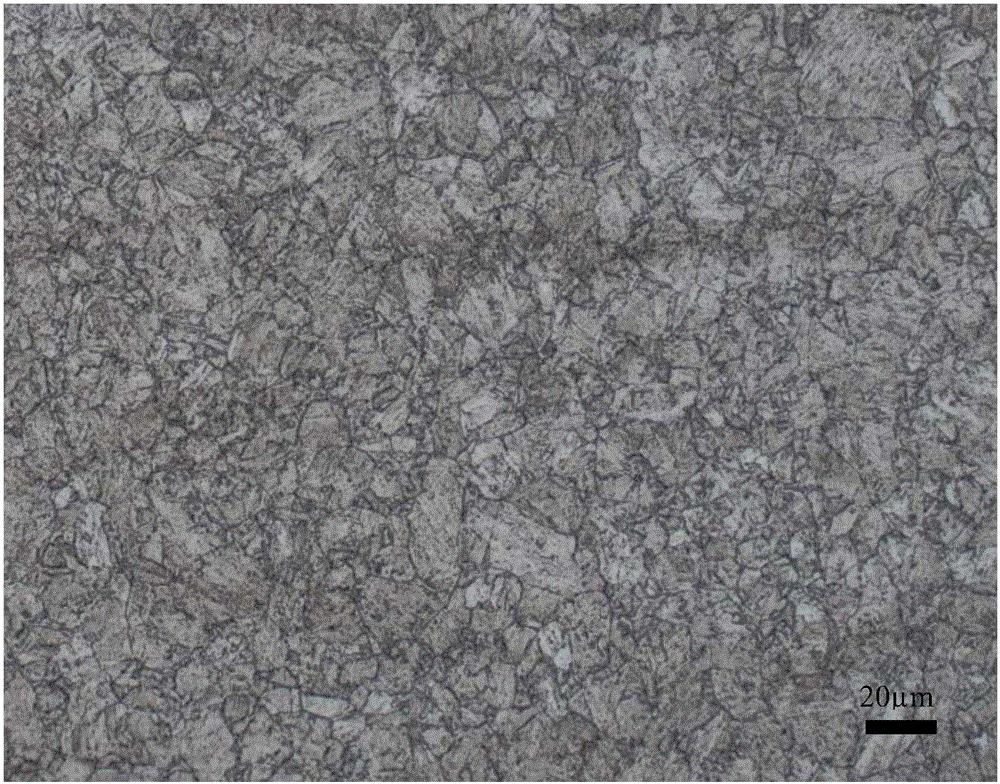

Embodiment 1

[0024] This example uses low-alloy chromium-molybdenum steel made of 26CrMo4, the mass percentage of which is C 0.24%-0.27%, Si 0.23%-0.28%, Mn 0.89%-0.94%, Cr 0.84%-0.92%, Mo0.16 %-0.19%. Tempering treatment.

[0025] The ratio of the metallographic etchant is: 8g of sulfosalicylic acid, 100mL of water, 1mL of nitric alcohol with a mass percentage of 4%, and 0.5mL of detergent.

[0026] Etching is carried out as follows:

[0027] 1. Sample production: After the cut sample is polished with a sample grinder, it is polished with W2.5 polishing paste to make the polished surface a smooth mirror surface without scratches.

[0028] 2. Proportion of corrosive agent: first configure the nitric acid alcohol with a mass percentage concentration of 4%, then dissolve 8g sulfosalicylic acid in 100mL water, stir well, pour it into a glass dish, add 1mL nitric acid alcohol (mass. The percentage concentration is 4%), 0.5mL detergent, and then put absorbent cotton into it, and let the abso...

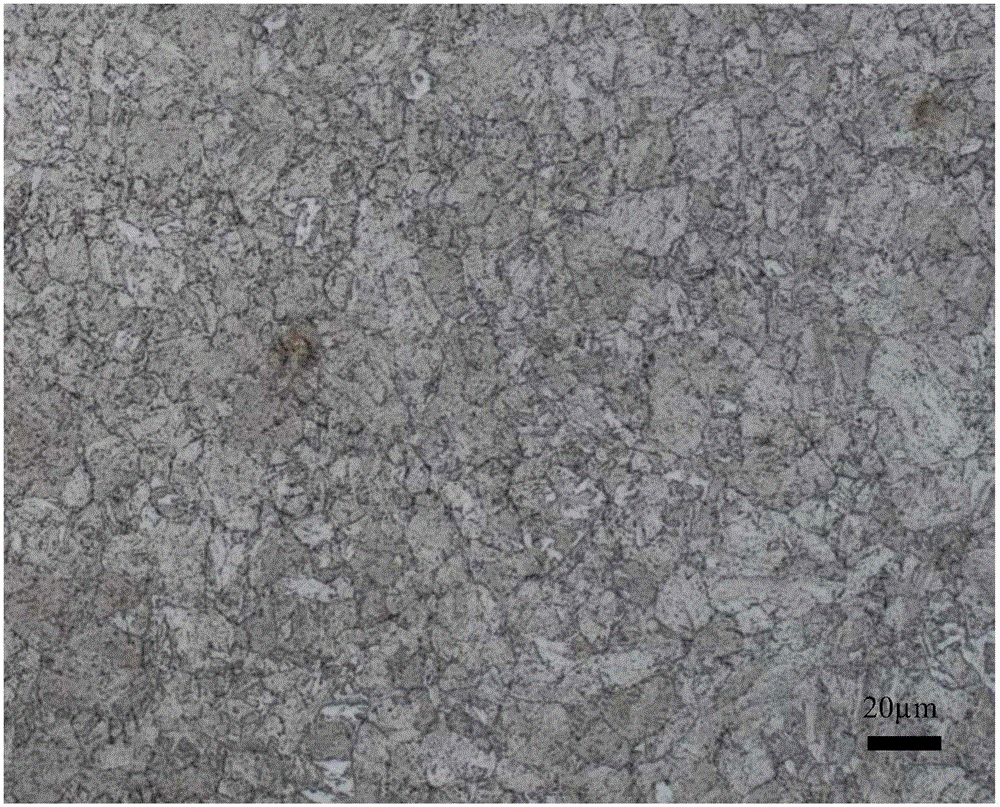

Embodiment 2

[0032] This example adopts the low-alloy chromium-molybdenum steel of 27CrMo47Vs, the mass percent of its composition is C 0.24%-0.27%, Si 0.23%-0.31%, Mn 0.40%-0.49%, Cr0.96%-1.01%, Mo0. 74%-0.80%. Tempering treatment.

[0033] The proportioning of the metallographic etchant is: 10g of sulfosalicylic acid, 100mL of water, 0.5mL of nitric alcohol (concentration of 4% by mass), and 1mL of detergent.

[0034] Etching is carried out as follows:

[0035] 1. Sample production: After the cut sample is polished with a sample grinder, it is polished with W2.5 polishing paste to make the polished surface a smooth mirror surface without scratches.

[0036] 2. Proportion of corrosive agent: first configure the nitric acid alcohol with a concentration of 4% by mass percentage, then dissolve 15g of sulfosalicylic acid in 100mL of water, stir evenly, pour it into a glass dish, and add 0.5mL of nitric acid alcohol ( mass percent concentration is 4%), 1mL of detergent, and then put absorbe...

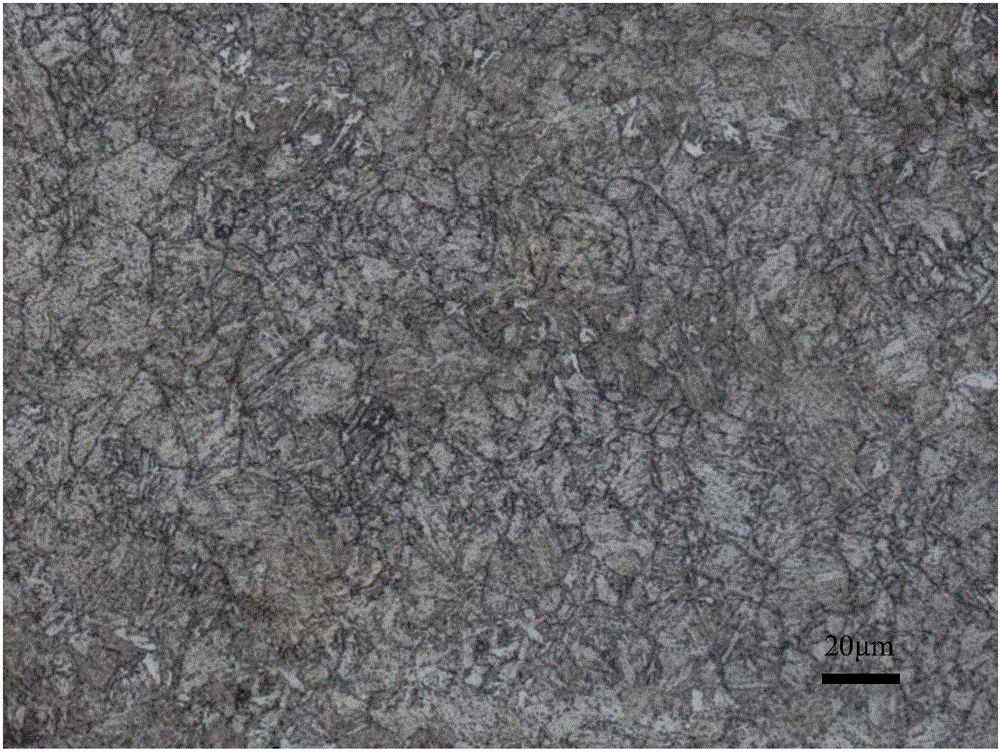

Embodiment 3

[0040] This example adopts the low-alloy chromium-molybdenum steel of 27CrMo44s, the mass percent of its composition is C 0.25%-0.28%, Si 0.21%-0.26%, Mn 0.62%-0.70%, Cr1.02%-1.10%, Mo0. 40%-0.43%. Tempering treatment.

[0041] The proportioning of the metallographic etchant is: 10g of sulfosalicylic acid, 100mL of water, 0.3mL of nitric alcohol (concentration of 4% by mass), 1mL of detergent.

[0042] Etching is carried out as follows:

[0043] 1. Sample production: After the cut sample is polished with a sample grinder, it is polished with W2.5 polishing paste to make the polished surface a smooth mirror surface without scratches.

[0044] 2. Proportion of corrosive agent: first configure nitric alcohol with a concentration of 4% by mass percentage, then dissolve 10 g of sulfosalicylic acid in 100 mL of water, stir well, pour it into a glass dish, and add 0.3 mL of nitric acid alcohol ( mass percent concentration 4%), 1mL of detergent, and then put absorbent cotton into i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com