Self-supported type corrugated straight heat exchange tube bundle

A heat exchange tube bundle, self-supporting technology, applied in the direction of heat exchanger shell, tubular element, heat exchange equipment, etc., can solve the problems of low heat transfer efficiency of heat exchange tube bundle, difficult processing of heat exchange tube bundle, low heat exchange efficiency and so on. , to achieve the effect of inhibiting the formation of dirt, eliminating the flow dead zone, and being easy to process and produce.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

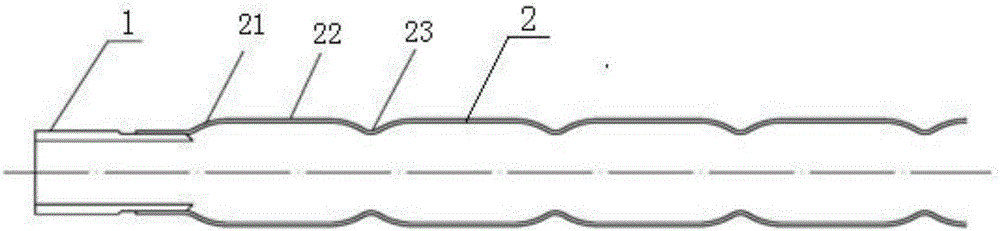

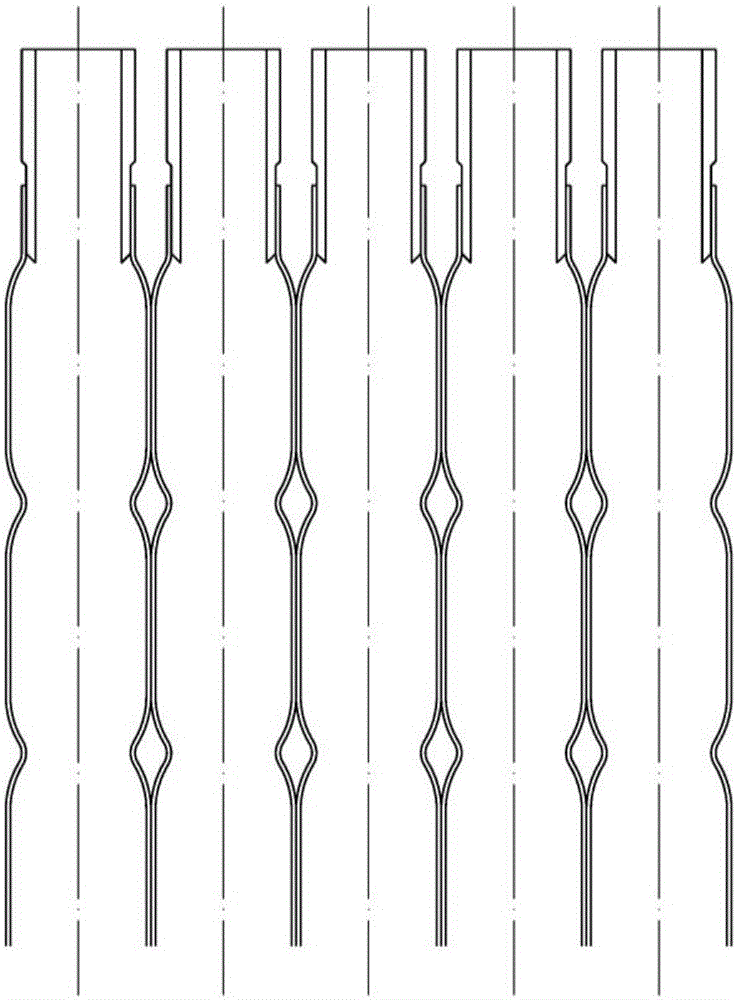

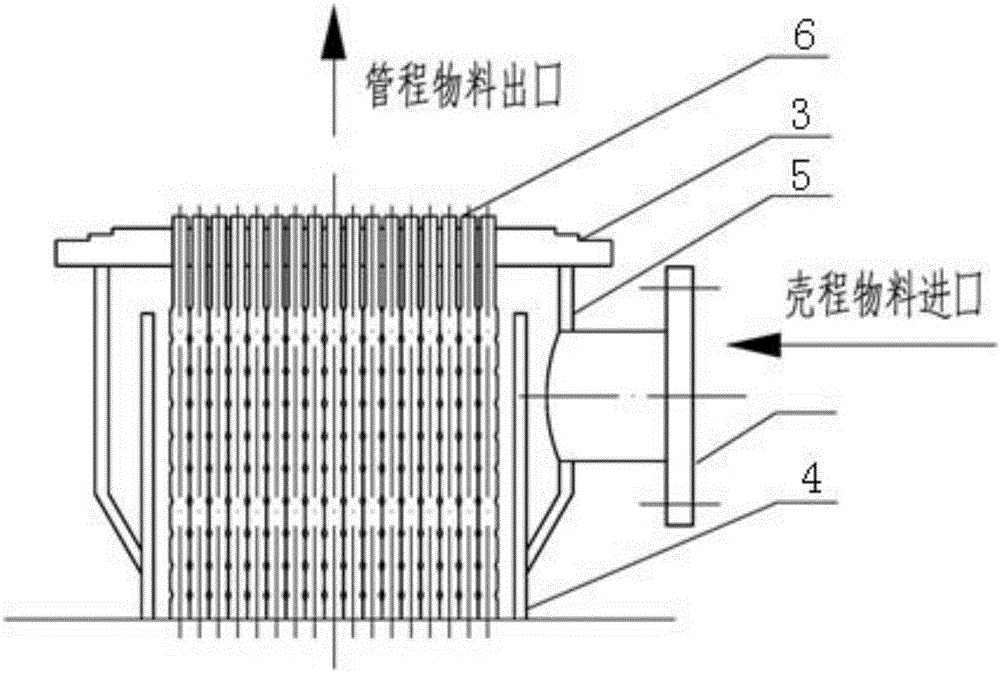

[0020] Such as figure 2 As shown, a self-supporting corrugated straight tube heat exchange tube bundle of the present invention includes a plurality of heat exchange tubes arranged in parallel, and each heat exchange tube is composed of a corrugated straight tube 2 and a smooth straight tube 1 (such as figure 1 As shown), the main body of the corrugated straight pipe 2 is a corrugated pipe section plus a straight pipe section structure, that is, a cycle of the waveform includes a peak 21-straight line section 22-peak 21-trough 23; the two ends of the corrugated straight pipe 2 are provided with a smooth straight pipe 1 Since it is fixedly connected with the tube sheet 3 in the heat exchanger, the heat exchange tubes are self-supporting through the line contact of the straight tube sections.

[0021] The corrugated straight pipe 2 is processed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com