Liquid gasification device and gasification method thereof

A gasification device and liquid technology, applied in the field of optical fiber preform, can solve the problems of unstable Buddha point, overheating, easy scaling of heating parts, etc., and achieve the effect of stable evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

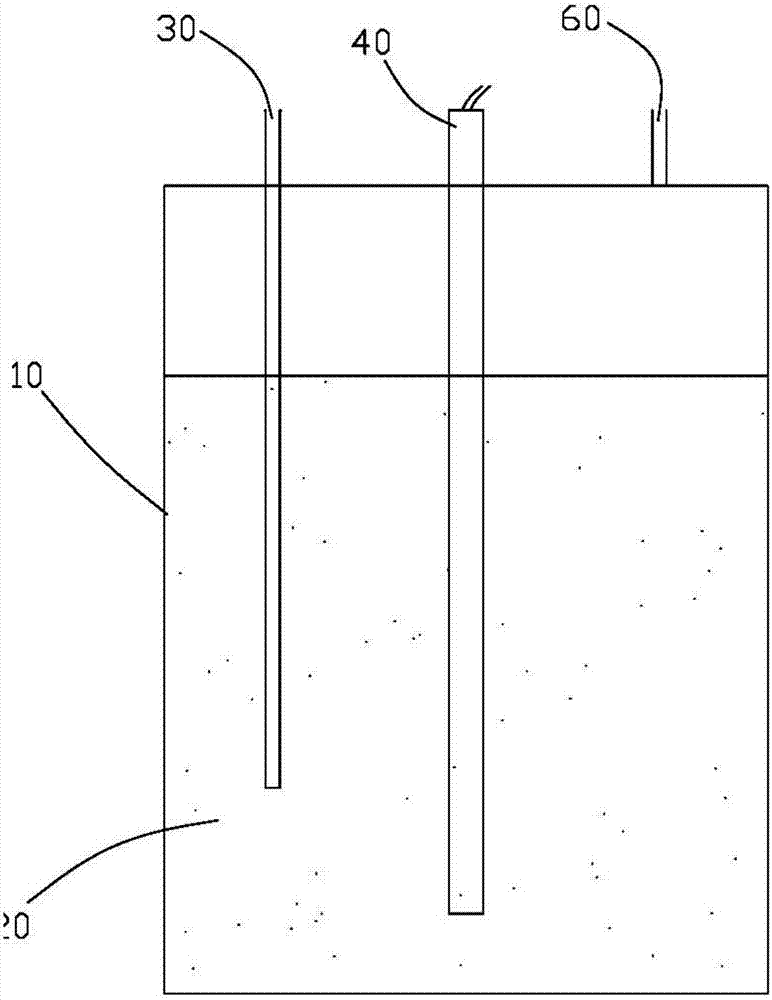

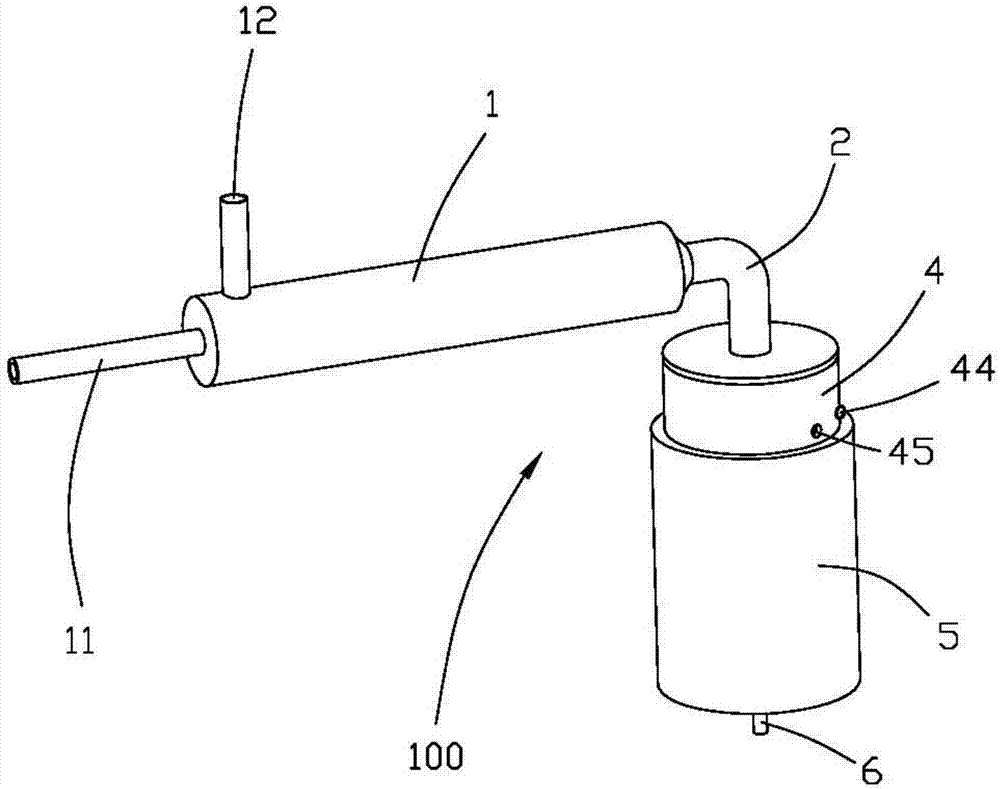

[0026] The present invention discloses a liquid vaporization device 100. The liquid vaporization device 100 vaporizes liquid chemicals (SiCl4, GeCl4, BBr3, POCl3, OMCTS, etc.) Rod manufacturing technology field.

[0027] see Figure 3 to Figure 5 As shown, the liquid vaporization device 100 includes: a first pipe body 1 , a second pipe body 2 connected to the first pipe body 1 , and a mist at the junction of the first pipe body 1 and the second pipe body 2 The carburetor 3, the gasifier inner shell 4 connected to the second pipe body 2, the electric heater 5 which partially accommodates the gasifier inner shell 4 and heats the gasifier inner shell 4, and the electric heater 5 The bottom of the heater 5 is connected to the third pipe body 6 communicating with the gasifier inner shell 4 , and the gasifier outer shell 7 located outside the gasifier inner shell 4 . Wherein, the third pipe body 6 passes through the shell 7 of the gasifier.

[0028] The liquid vaporization device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com