Preparation method of high-temperature water-retention modified cellulose ether

A technology of water-soluble cellulose and cellulose ether, which is applied in the field of preparation of high-temperature water-retaining modified cellulose ether, can solve problems such as product instability and low gel temperature, and achieve high temperature resistance, high gel temperature, The effect of product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

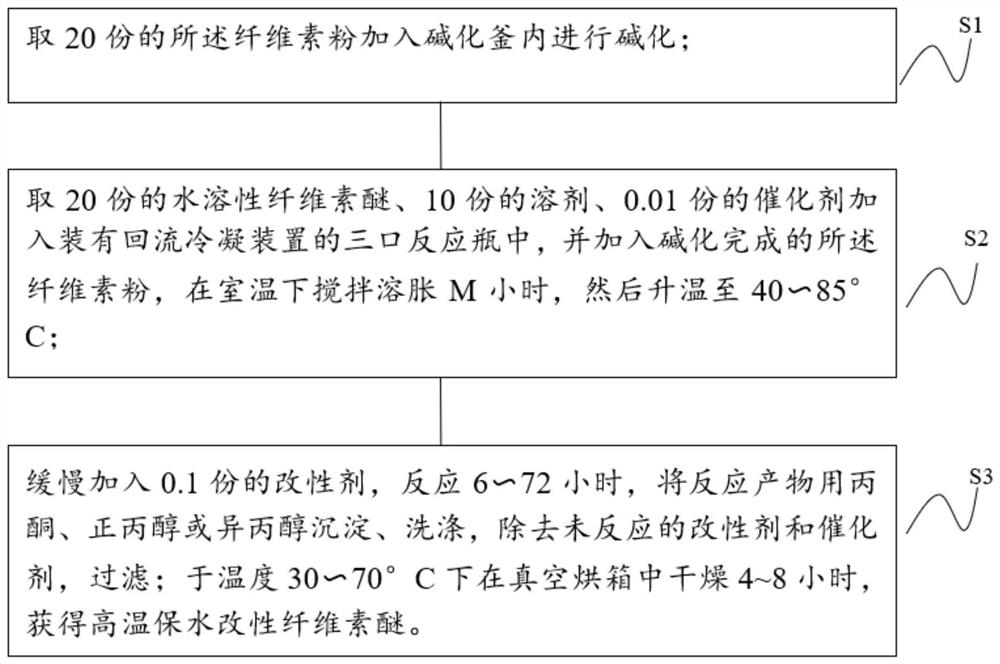

[0023] Example 1, see figure 1 , the present invention provides a preparation method of high temperature water retention modified cellulose ether, the preparation method of said high temperature water retention modified cellulose ether is composed of 20 parts of cellulose powder and 20 parts of water Cellulose ether, 0.1 part modifier, 0.01 part catalyst and 10 parts solvent.

[0024] A preparation method of high temperature water retention modified cellulose ether, comprising the following steps:

[0025] S1: get 20 parts of described cellulose powders and add in the alkalization kettle to carry out alkalization;

[0026] S2: get 20 parts of water-soluble cellulose ether, 10 parts of solvent, 0.01 part of catalyst and add it into a three-necked reaction flask equipped with a reflux condensing device, and add the alkalized cellulose powder, stir and swell at room temperature M hours, then warm to

[0027] S3: Slowly add 0.1 part of modifier, react Precipitate and wash t...

Embodiment 2

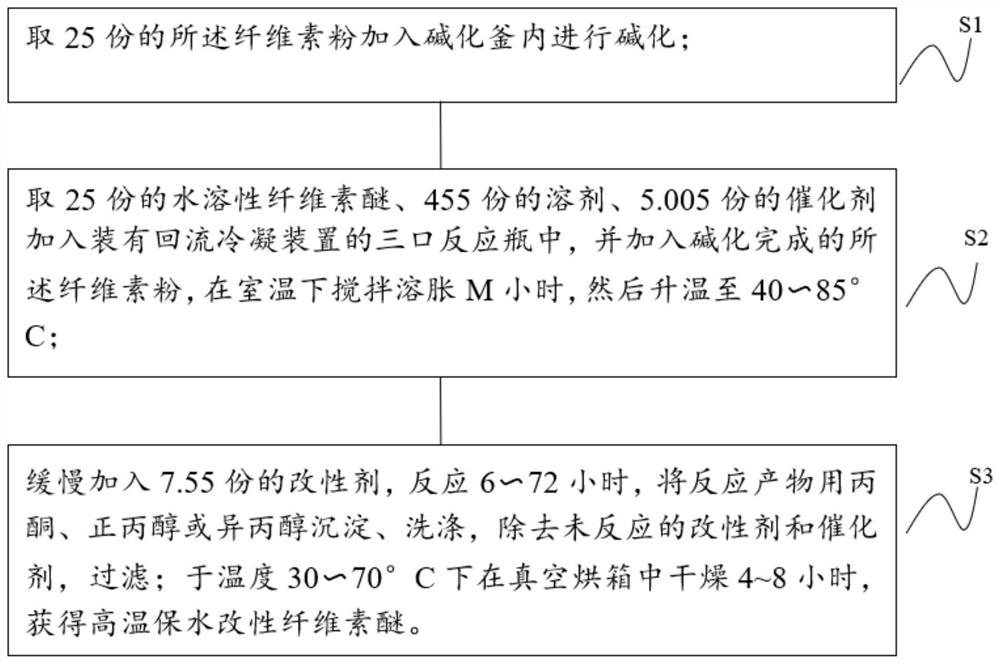

[0030] Example 2, see figure 2 , the present invention provides a preparation method of high temperature water retention modified cellulose ether, the preparation method of the high temperature water retention modified cellulose ether is composed of 25 parts of cellulose powder and 25 parts of water-soluble cellulose powder according to the following parts by weight of raw materials Cellulose ether, 7.55 parts modifier, 5.005 parts catalyst and 455 parts solvent.

[0031] A preparation method of high temperature water retention modified cellulose ether, comprising the following steps:

[0032] S1: get 25 parts of the described cellulose powder and add it in the alkalization kettle to carry out alkalization;

[0033] S2: get 25 parts of water-soluble cellulose ethers, 455 parts of solvents, 5.005 parts of catalysts and add them into the three-necked reaction flask equipped with the reflux condensing device, and add the alkalized cellulose powder, stir and swell at room temper...

Embodiment 3

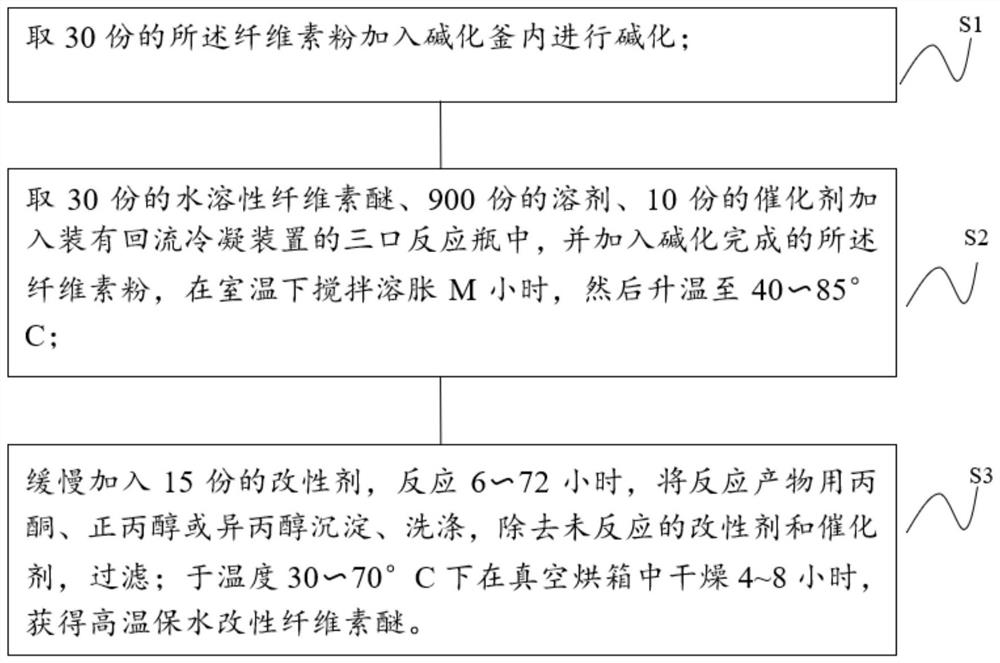

[0037] Example 3, see image 3 , the present invention provides a preparation method of high temperature water retention modified cellulose ether, the preparation method of said high temperature water retention modified cellulose ether is composed of 30 parts of cellulose powder and 30 parts of water-soluble cellulose ether according to the following parts by weight of raw materials Cellulose ether, 15 parts modifier, 10 parts catalyst and 900 parts solvent.

[0038] A preparation method of high temperature water retention modified cellulose ether, comprising the following steps:

[0039] S1: get 30 parts of the described cellulose powders and add in the alkalization kettle to carry out alkalization;

[0040] S2: get 30 parts of water-soluble cellulose ethers, 900 parts of solvents, 10 parts of catalysts and add them into a three-necked reaction flask equipped with a reflux condensing device, and add the alkalized cellulose powder, stir and swell at room temperature M hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com