A kind of drying method of lithium ion battery cell

A lithium-ion battery and drying method technology, which is applied in the direction of drying solid materials, method combination to dry solid materials, drying, etc., can solve the problems that batteries are difficult to adapt to industrial production, and achieve cost reduction and efficiency increase product quality and cost reduction , the effect of reducing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

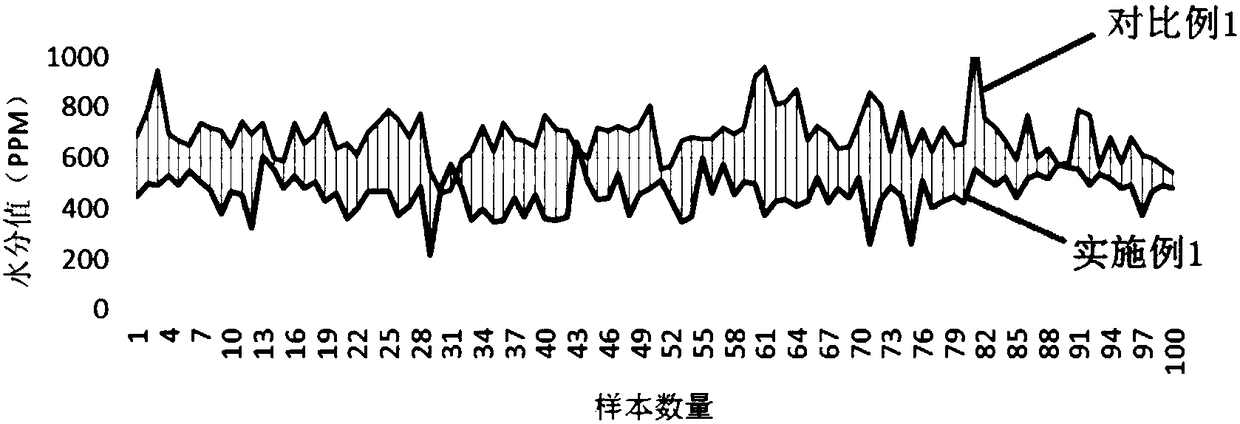

Embodiment 1

[0031] The drying method of the lithium-ion battery cell of the present embodiment, the technological process is as follows Figure 4 shown, including the following steps:

[0032] 1) Put the lithium-ion battery cell (the cell is prepared by lamination of positive electrode, negative electrode, and diaphragm, placed in an unsealed shell, with a monomer capacity of 20Ah, a total of 200 pieces) in a drying oven , evacuated to a vacuum degree below 200Pa, the time used is 8min (h in formula 1);

[0033] 2) Simultaneously perform heating, air inflation, and blasting operations, control the temperature in the drying furnace to rise to 90°C (time-consuming 20min), fill nitrogen to a vacuum of 85kPa (time-consuming ≤ 1min), and reach the set temperature and vacuum degree Insulation and pressure holding; the time used for the whole process is 2.5h (h in formula 1 1 ), during which the blowing continues;

[0034] 3) Stop the blowing and nitrogen filling operations, maintain the temp...

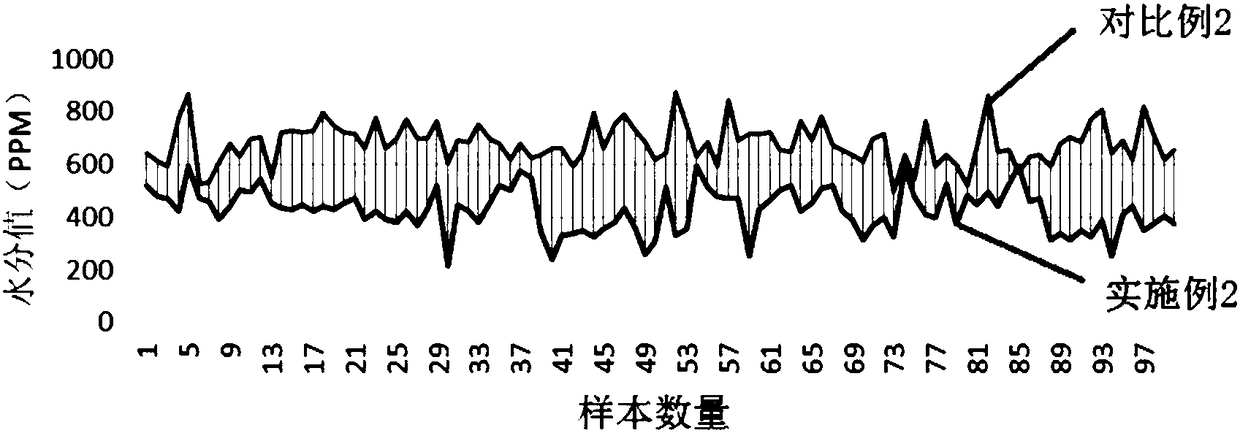

Embodiment 2

[0039] The drying method of the lithium-ion battery cell of the present embodiment may further comprise the steps:

[0040] 1) Put the lithium-ion battery cell (the cell is prepared by lamination of positive electrode, negative electrode, and diaphragm, placed in an unsealed shell, with a monomer capacity of 72Ah, a total of 200 pieces) in a drying oven , evacuated to a vacuum degree below 200Pa, the time used is 10min (h in formula 1);

[0041] 2) Simultaneously perform heating, air inflation, and blasting actions, control the temperature in the drying furnace to rise to 95°C (time-consuming 25min), fill nitrogen to a vacuum degree of 90kPa (time-consuming ≤ 1min), and reach the set temperature and vacuum degree Insulation and pressure holding; the time used for the whole process is 3.5h (h in formula 1 1 ), during which the blowing continues;

[0042] 3) Stop the blowing and nitrogen filling operations, maintain the temperature in the drying furnace at 95°C, evacuate to a ...

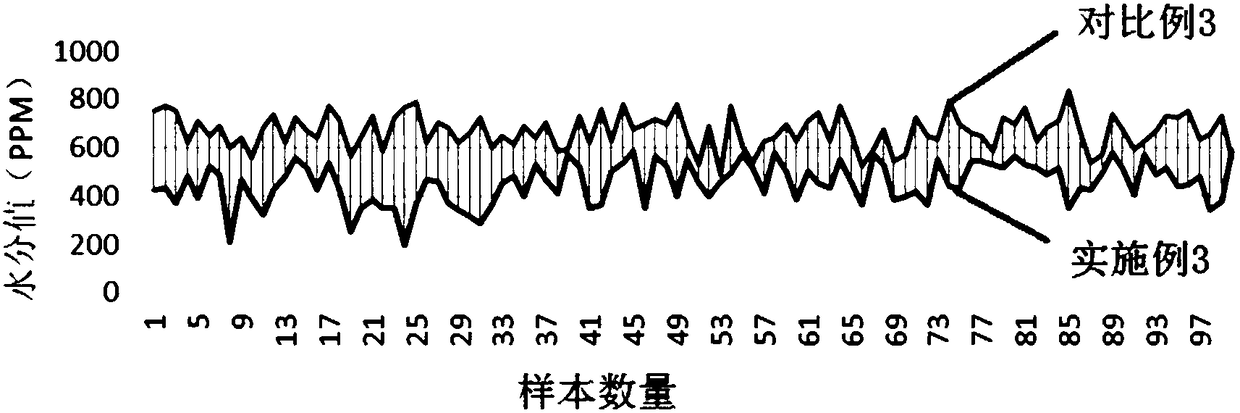

Embodiment 3

[0047] The drying method of the lithium-ion battery cell of the present embodiment may further comprise the steps:

[0048] 1) Put the lithium-ion battery cell (the cell is made of positive electrode, negative electrode, and diaphragm by lamination, placed in an unsealed shell, with a monomer capacity of 100Ah) in a drying oven, and vacuum to The vacuum degree is below 200Pa, and the time used is 12min (h in formula 1);

[0049] 2) Simultaneously perform heating, air inflation, and blasting actions, control the temperature in the drying furnace to rise to 110°C (time-consuming 30min), fill nitrogen to a vacuum of 95kPa (time-consuming ≤ 1min), and reach the set temperature and vacuum degree Insulation and pressure holding; the time used for the whole process is 5h (h in formula 1 1 ), during which the blowing continues;

[0050] 3) Stop the blowing and nitrogen filling operations, maintain the temperature in the drying furnace at 110°C, evacuate to a vacuum degree of 90Pa (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com