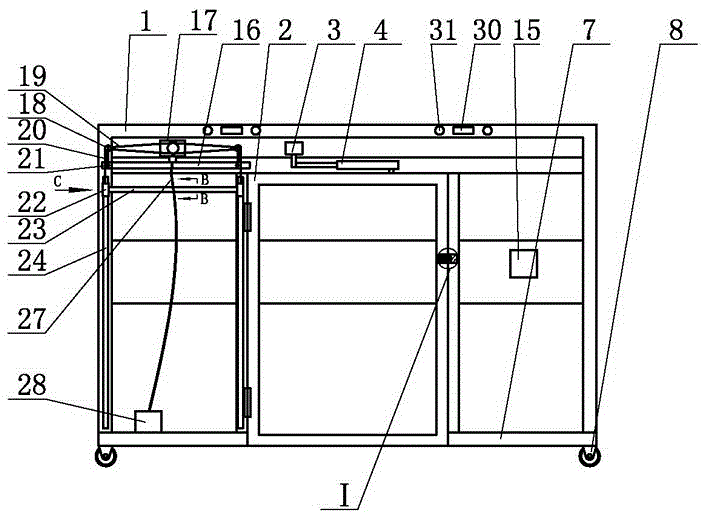

Intelligent safety enclosure

A technology for safety fences and fences, applied to fences, door/window accessories, power control mechanisms, etc., can solve problems such as inability to complete inspection work, and achieve the effects of low manufacturing cost, simple and compact structure, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

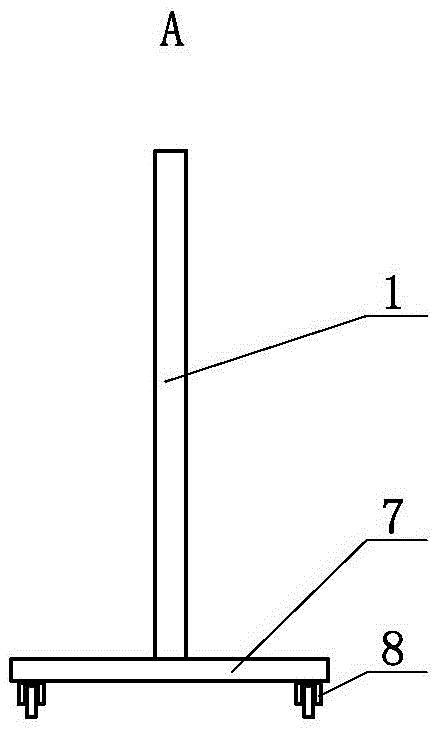

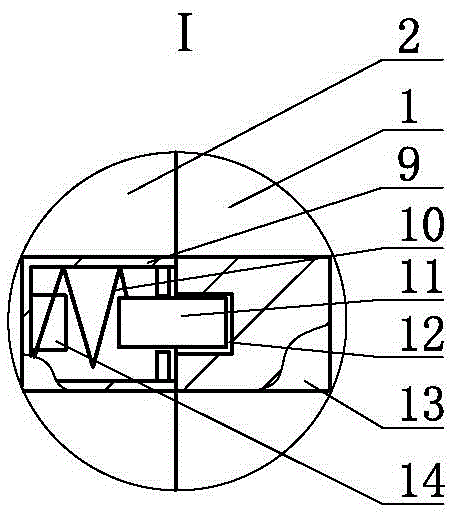

Method used

Image

Examples

Embodiment 1

[0028] Rust cleaning agent, composed of the following raw materials: isocyanate modified phenolic resin 1kg, sodium silicate 2kg, sodium tripolyphosphate 2kg, anionic surfactant polyacrylamide 1 kg, borax 1 kg, sodium metabisulfite 2 kg, silicone oil 1 kg , Glutaric acid 2kg, oxalic acid 1 kg, corrosion inhibitor zinc borate 2 kg and water 110 kg.

[0029] The isocyanate-modified phenolic resin was prepared according to the following steps: in parts by weight, 1 kg of phenol, 0.5 kg of benzaldehyde, 0.01 kg of catalyst zinc oxide and 0.2 parts of TDI trimer were added to the reactor, and the temperature was raised to 50°C for reaction After 1 hour, the reaction was stopped, and the filtrate obtained by filtration was an isocyanate modified phenolic resin.

Embodiment 2

[0031] Rust removal cleaning agent, composed of the following raw materials: isocyanate modified phenolic resin 3kg, sodium silicate 5kg, sodium tripolyphosphate 6kg, anionic surfactant α-sulfomonocarboxylate 2kg, borax 3kg, sodium metabisulfite 5kg, silicone oil 3kg, 6kg of glutaric acid, 3kg of oxalic acid, 5kg of corrosion inhibitor zinc hydroxide and 90kg of water;

[0032] The isocyanate-modified phenolic resin is prepared according to the following steps: In parts by weight, 2kg of phenol, 1.5kg of benzaldehyde, 0.03kg of catalyst magnesium oxide and 0.5kg of HDI trimer are added into the reactor, and the temperature is raised to 60°C for reaction After 2 hours, the reaction was stopped, and the filtrate obtained by filtration was an isocyanate modified phenolic resin.

Embodiment 3

[0034] Rust cleaning agent, consisting of the following raw materials: isocyanate modified phenolic resin 1.5kg, sodium silicate 4kg, sodium tripolyphosphate 5kg, anionic surfactant fatty acid sulfoalkyl ester 1.2kg, borax 2.5kg, sodium metabisulfite 3kg, silicone oil 1.5kg, glutaric acid 4kg, oxalic acid 1.5kg, corrosion inhibitor polyaspartic acid 3kg and water 105kg;

[0035] The isocyanate-modified phenolic resin was prepared according to the following steps: In parts by weight, 1.4 kg of phenol, 0.8 kg of benzaldehyde, 0.02 kg of catalyst and 0.4 kg of IPDI trimer were added to the reactor, and the temperature was raised to 55°C for 1.5 kg reaction. After hours, the reaction was stopped, and the filtrate obtained by filtration was an isocyanate modified phenolic resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com