A kind of non-curing rubber asphalt spraying construction equipment

A technology of non-curing rubber and construction equipment, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, melting processing of tar asphalt/petroleum asphalt/natural asphalt, heating processing of tar asphalt/petroleum asphalt/natural asphalt, etc. Solve the problems that the equipment cannot move automatically, wear and tear, and cannot monitor the temperature of the rubber asphalt coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

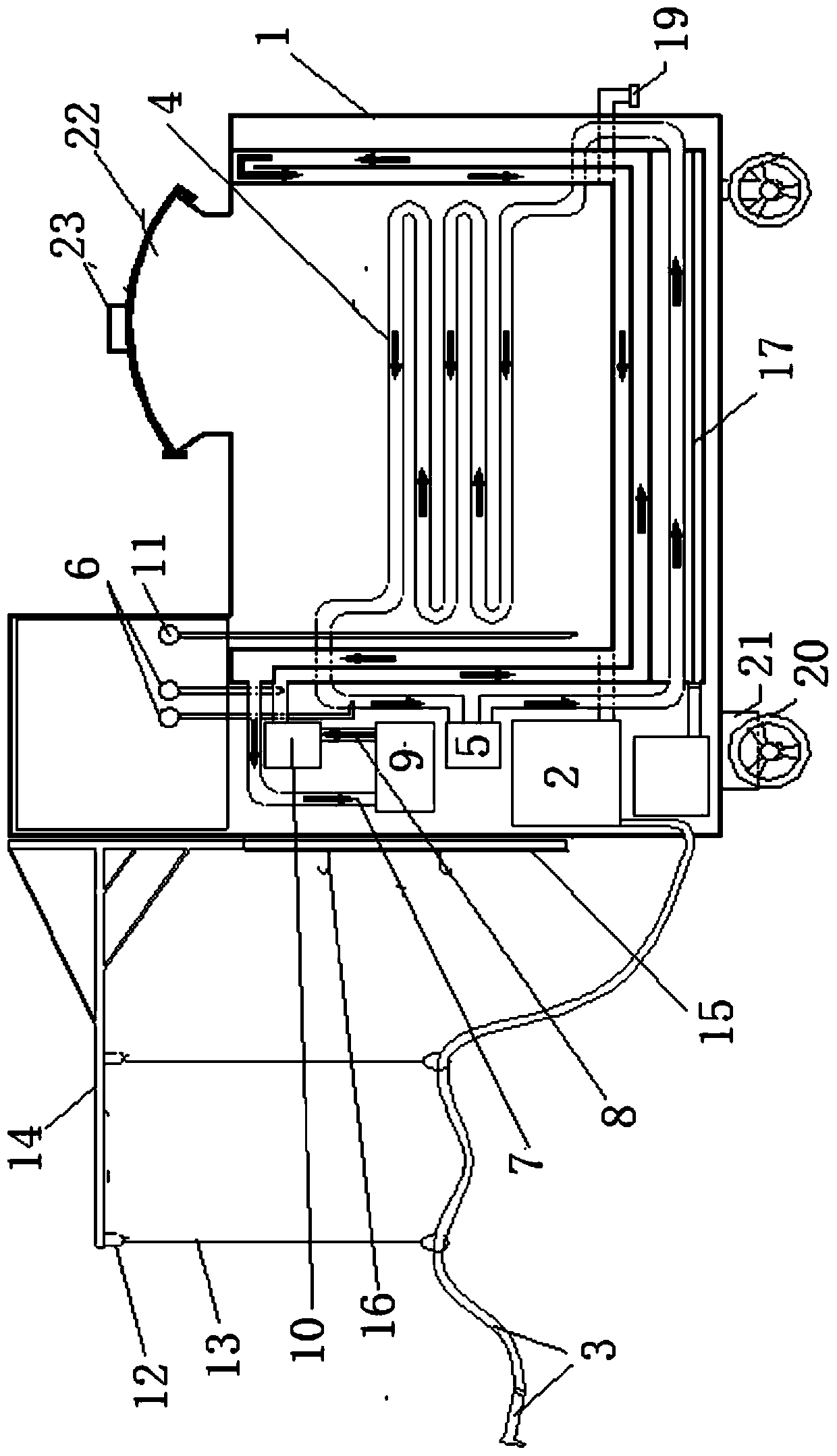

[0024] Below in conjunction with accompanying drawing, the utility model is described in detail.

[0025] In the figure, the non-cured rubber asphalt spraying construction equipment includes a storage tank 1, which is an important part of the equipment and is an area for heating, temperature adjustment and heat preservation of asphalt paint.

[0026] The upper part of the storage barrel 1 is a heating area, and the lower part is a cooling and heat preservation area. A heat transfer oil heating system 1 is placed in the storage barrel 1 heating area. Cured asphalt paint or non-cured rubberized asphalt paint. After the paint is heated, it enters the cooling and heat preservation area, in which the heating system 2 is installed in the cooling and heat preservation area, and the heating system 2 performs temperature adjustment and heat preservation treatment on the heated and melted paint to control the temperature of the paint; the sprayer 2 is set in the temperature reduction an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com