Fluorescent silk fiber based on BODIPY dyes and preparation method of fluorescent silk fiber

A technology for silk fibers and dyes, applied in the field of fluorescent silk fibers and their preparation, can solve the problems of affecting the use effect, low degree of combination of fluorescent substances and silk fibers, uneven fluorescence intensity, etc., and achieves improved degree of combination and excellent light stability. , the effect of high fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

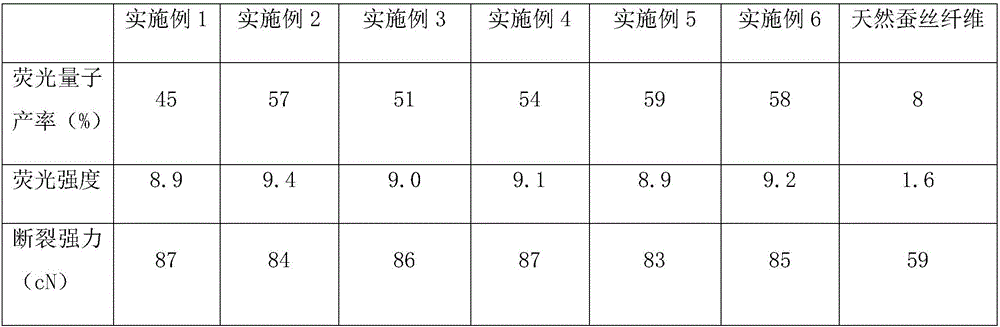

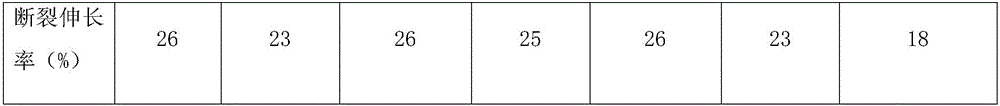

Examples

Embodiment 1

[0027] (1) After the white natural silk fiber is degummed, it is immersed in warm water at 30°C for oscillating swelling for 10 minutes, and then immersed in an aqueous solution of 50 microns of manganese oxide modified zeolite with a mass fraction of 0.5%. Ultrasound for 30 minutes, take out and wash with water, and dry naturally to obtain pretreated natural silk fibers.

[0028] (2) The pretreated natural silk fiber prepared in step (1) is first immersed in 5 g / ml of quaternary ammonium salt type fluoroborate dipyrrole dye with a bath ratio of 1:40, taken out, and then immersed in 2% Low-molecular-weight chitosan solution, taken out, then immersed in 5g / ml quaternary ammonium salt type fluoroborate dipyrrole dye, taken out, finally immersed in low-molecular-weight chitosan solution with a mass fraction of 2%, taken out and dried to obtain fluorescent dyed silk fiber;

[0029] (3) Steam the fluorescently dyed silk fiber prepared in step (2) with ethanol water vapor with a vo...

Embodiment 2

[0031] (1) After the yellow natural silk fiber is degummed, it is immersed in warm water at 45°C for oscillating swelling for 30 minutes, and then immersed in an aqueous solution of 100 microns of manganese oxide modified zeolite with a mass fraction of 5%. Ultrasound for 60 minutes, take out, wash with water, and dry naturally to obtain pretreated natural silk fibers.

[0032] (2) The pretreated natural silk fiber prepared in step (1) is first immersed in 15g / ml sulfonate type fluoroborate dipyrrole dye with a bath ratio of 1:40, taken out, and then immersed in 3% Low-molecular-weight chitosan solution, taken out, then immersed in 15g / ml sulfonate type fluoroborate dipyrrole dye, taken out, finally immersed in low-molecular-weight chitosan solution with a mass fraction of 3%, taken out and dried to obtain fluorescent dyed silk fiber;

[0033] (3) Steam the fluorescently dyed silk fiber prepared in step (2) with ethanol water vapor with a volume ratio of 1:1 for 20 minutes, h...

Embodiment 3

[0035] (1) After the colored natural silk fiber has been degummed, it is immersed in warm water at 35°C for 20 minutes, and then immersed in an aqueous solution of 70 microns of manganese oxide modified zeolite with a mass fraction of 1%. Ultrasound for 40 minutes, take out, wash with water, and dry naturally to obtain pretreated natural silk fibers.

[0036](2) The pretreated natural silk fiber prepared in step (1) is first immersed in 10 g / ml of quaternary ammonium salt type fluoroborate dipyrrole dye with a bath ratio of 1:40, taken out, and then immersed in a 2.5% mass fraction of Low-molecular-weight chitosan solution, taken out, then immersed in 10g / ml quaternary ammonium salt type fluoroborate dipyrrole dye, taken out, finally immersed in low-molecular-weight chitosan solution with a mass fraction of 2.5%, taken out and dried to obtain fluorescent dyed silk fiber;

[0037] (3) The fluorescently dyed silk fiber prepared in step (2) was steamed with ethanol water vapor w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com