Water-based super-thin steel structure fire-retardant coating

A fireproof coating, ultra-thin technology, applied in the field of coatings, can solve the problems of labor and material, affect the appearance, complex construction, etc., achieve the effect of convenient construction, good decoration, and meet the fire protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

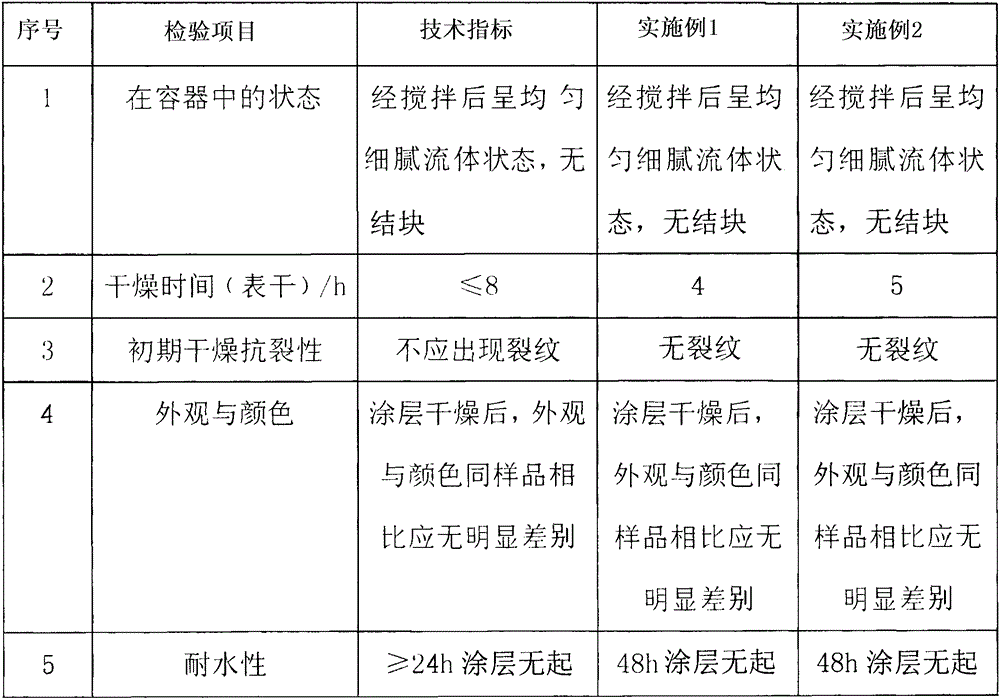

Examples

Embodiment 1

[0014] A water-based ultra-thin steel structure fireproof coating, including the following raw materials in weight percentage: 25% of ammonium polyphosphate with a polymerization degree of 2000, 6% of melamine, 8% of pentaerythritol with a purity of 99.8%, 7% of titanium dioxide, and 5% of zinc borate , talcum powder 2%, acrylic resin 20%, water 27%. Weigh the raw materials in the above weight percentages in turn, and add them into the ball mill; ball mill for 15 hours, adjust the viscosity at the same time, and test the fineness; discharge when the viscosity is 300±50S, and the fineness is ≤100um, and the fireproof coating is obtained.

Embodiment 2

[0016] A water-based ultra-thin steel structure fireproof coating, including the following raw materials in weight percentage: 26% of ammonium polyphosphate with a polymerization degree of 2000, 8% of melamine, 9% of pentaerythritol with a purity of 99.8%, 8% of titanium dioxide, and 6% of zinc borate , talcum powder 3%, acrylic resin 20%, water 20%. Weigh the raw materials in the above weight percentages in sequence, and add them into the ball mill; ball mill for 17 hours, adjust the viscosity at the same time, and test the fineness; discharge when the viscosity is 300±50S and the fineness is ≤100um, and the fireproof coating is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com