Special optical polyester synthesis catalyst and preparation method and application thereof

A catalyst and co-catalyst technology, which is applied in the field of special catalysts for optical polyester synthesis, can solve problems such as unsatisfactory polycondensation activity, and achieve the effects of easier control of product quality stability, improved environmental friendliness, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

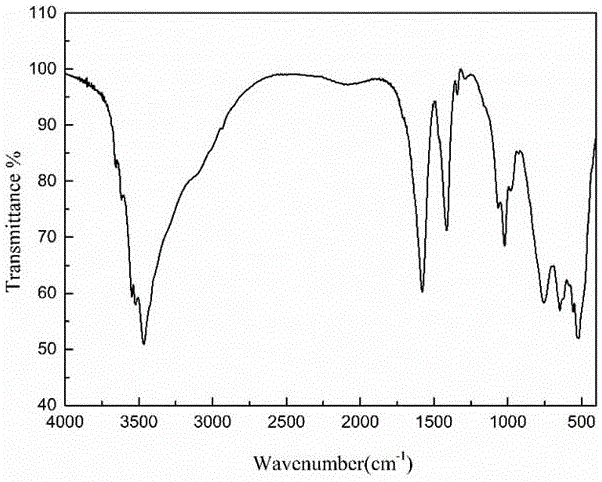

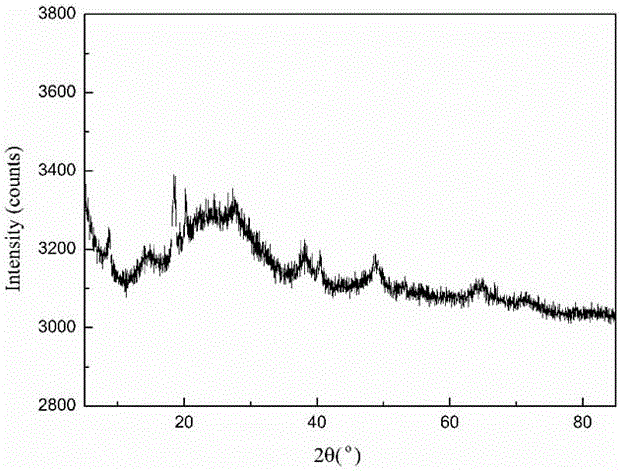

[0075] Heat, stir and hydrolyze 2 g of basic aluminum acetate in 0.02 g of sodium acetate in deionized water (100 mL in volume) at 100°C for 2 hours, then cool and stand for 0.5 hours to discard the precipitate to obtain γ-AlOOH hydrogel;

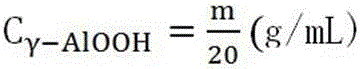

[0076] Add 100mL of ethylene glycol to the obtained γ-AlOOH hydrogel, distill off water at 70°C under reduced pressure, and obtain a γ-AlOOH-ethylene glycol dispersion after filtration, the measured concentration is 0.0193g / mL;

[0077] Measure 50ml of γ-AlOOH-ethylene glycol dispersion, add ethylene glycol antimony (2.4125g) with a mass ratio of 10:4 to γ-AlOOH, stir well and filter to obtain a special catalyst for optical polyester synthesis (total mass Concentration 0.067 g / mL);

[0078] Use 1.2mL of this catalyst to catalyze terephthalic acid (200g) and ethylene glycol to synthesize polyethylene terephthalate (direct esterification method, alkyd ratio 1.3) in a polyester synthesis kettle, and the esterification temperature is 265 °C, t...

Embodiment 2

[0080] Heat, stir and hydrolyze 2 g of basic aluminum acetate in 0.08 g of sodium acetate in deionized water (volume 100 mL) at 90°C for 3 hours, then cool and stand for 0.5 hours to discard the precipitate to obtain γ-AlOOH hydrogel;

[0081] Add 100mL of ethylene glycol to the obtained γ-AlOOH hydrogel, distill off water at 80°C under reduced pressure, and obtain a γ-AlOOH-ethylene glycol dispersion after filtration, the measured concentration is 0.0197g / mL;

[0082] Measure 50ml of γ-AlOOH-ethylene glycol dispersion, add antimony acetate (2.4625g) with a mass ratio of γ-AlOOH of 10:4, stir well and filter to prepare a special catalyst for optical polyester synthesis (total mass concentration 0.068 g / mL);

[0083] Use 1.17mL of this catalyst to catalyze terephthalic acid (200g) and ethylene glycol to synthesize polyethylene terephthalate (direct esterification method, alkyd ratio 1.3) in a polyester synthesis kettle, and the esterification temperature is 265 °C, the end poi...

Embodiment 3

[0085] Heat and stir 2 g of basic aluminum acetate under the action of 0.1 g of sodium acetate in deionized water (volume 100 mL) at 100 ° C for 2 hours for hydrolysis, then cool and stand for 1 hour to discard the precipitate to obtain γ-AlOOH hydrogel;

[0086] Add 100mL of ethylene glycol to the obtained γ-AlOOH hydrogel, distill off water at 80°C under reduced pressure, and obtain a γ-AlOOH-ethylene glycol dispersion after filtration, the measured concentration is 0.0195g / mL;

[0087] Measure 50ml of γ-AlOOH-ethylene glycol dispersion, add ethylene glycol antimony (4.875g) with a mass ratio of 5:1 to γ-AlOOH, stir well and filter to prepare a special catalyst for optical polyester synthesis (total mass Concentration 0.117g / mL);

[0088] Use 0.52mL of this catalyst to catalyze terephthalic acid (200g) and ethylene glycol to synthesize polyethylene terephthalate (direct esterification method, alkyd ratio 1.3) in a polyester synthesis kettle, and the esterification temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com