Baking-free bricks with high nickel slag proportion and preparation method therefor

A high-volume, non-burning brick technology, used in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as environmental pollution and large footprint, improve performance and reduce grinding difficulty , the effect of enhancing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

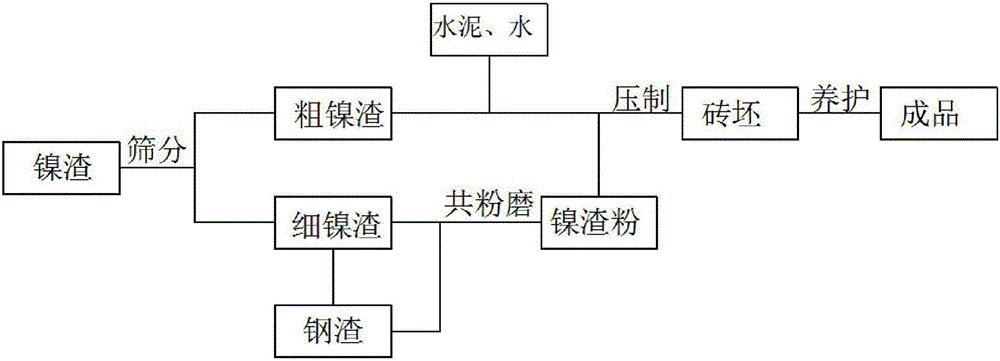

Method used

Image

Examples

Embodiment 1

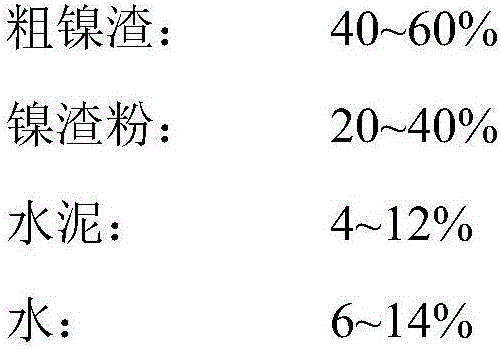

[0027] The high-volume nickel slag free-burning bricks provided by the present embodiment are made of the following raw materials by mass percentage:

[0028]

[0029] The sum of the mass percentages of the above-mentioned raw materials is 100%.

[0030] Among them, the particle size and coarse nickel slag are obtained by the following methods: firstly, the nickel slag is sieved and classified, and the particle size of the nickel slag is 0 to 9 mm, and the gradation of the nickel slag is analyzed by using a standard set of sieves to determine and distinguish the particle size. The differentiated particle size is determined according to the cumulative sieve residue, and the particle size with the cumulative sieve residue of 40-70% is used as the differentiated particle size. After testing, the differentiated particle size of this embodiment is 1.18mm, and the proportion of coarse nickel slag larger than 1.18mm is 63.2%. The proportion of fine nickel slag smaller than 1.18mm ...

Embodiment 2

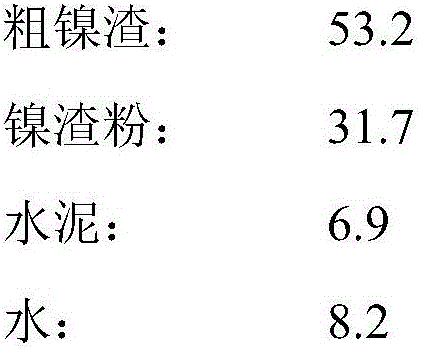

[0036] The high-volume nickel slag free-burning bricks provided by the present embodiment are made of the following raw materials by mass percentage:

[0037]

[0038] The sum of the mass percentages of the above-mentioned raw materials is 100%.

[0039] Among them, the distinguishing particle size and coarse nickel slag are obtained by the following methods: firstly, the nickel slag is sieved and classified, and the particle size of the nickel slag is 0-8.5 mm, and the gradation of the nickel slag is analyzed by using a standard set of sieves to determine the distinguishing particle size. , the distinguishing particle size is determined according to the cumulative sieve residue, and the particle size with the cumulative sieving residue of 40-70% is used as the distinguishing particle size. After testing, the distinguishing particle size of this embodiment is 2.36mm, and the proportion of coarse nickel slag larger than 2.36mm is 53.2%. , the proportion of fine nickel slag s...

Embodiment 3

[0045] The high-volume nickel slag free-burning bricks provided by the present embodiment are made of the following raw materials by mass percentage:

[0046]

[0047] The sum of the mass percentages of the above-mentioned raw materials is 100%.

[0048] The distinguishing particle size and coarse nickel slag are obtained by the following methods: Firstly, the nickel slag is sieved and classified, and the gradation of the nickel slag is analyzed by using a standard set of sieves to determine the distinguishing particle size. The particle size with a sieve residue of 40-70% is used as the distinguishing particle size. After testing, the distinguishing particle size in this embodiment is 1.18mm, the proportion of coarse nickel slag larger than 1.18mm is 58.2%, and the fine nickel slag smaller than 1.18mm is all. The proportion is 41.8%.

[0049] The nickel slag powder is obtained by the following method: the fine nickel slag and the steel slag with a particle size of 1.0-2.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com