Cemented filling material for mine and preparation method thereof

A cemented filling material and mining technology, applied in the field of mineral resources development, can solve the problems of cemented body strength loss, limited processing capacity, complex process, etc., and achieve the effects of wide particle size distribution, short maintenance period, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

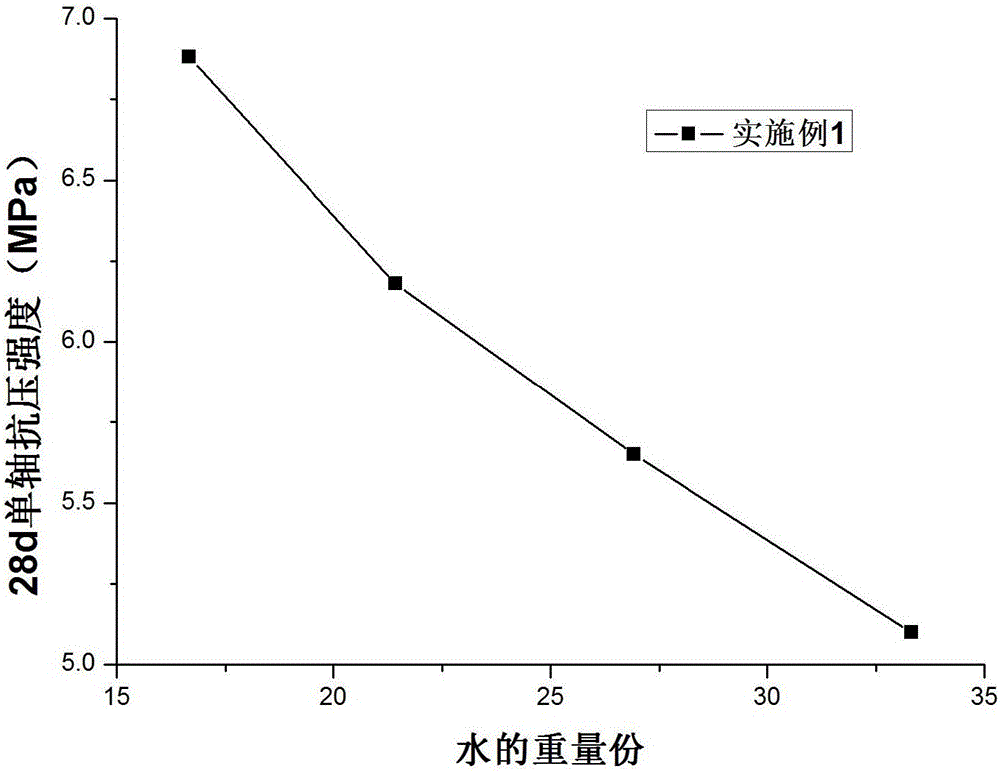

Embodiment 1

[0041] Embodiment 1: In the present embodiment, the cemented filling material for mine is mainly composed of the following parts by weight (higher strength):

[0042]

[0043] The amount of flocculant added is 10g / t, and the mass concentration of flocculant aqueous solution is 0.1% (because the amount of flocculant added is much smaller than that of other materials, and the mass concentration of flocculant is a fixed value of 0.1%, the amount of flocculant added is calculated separately).

[0044] The bone powder is C10 Huazhong bone powder, and the tailings are all tailings.

[0045] The flocculant is an anionic polyacrylamide with a molecular weight of 20 million, which has the properties of flocculation, thickening, shear resistance, drag reduction, and dispersibility. The strength and economic index of the filling material are determined.

[0046] The preparation method of filling slurry is as follows: 1) Weigh the corresponding weight of bone powder, tailings and wate...

Embodiment 2

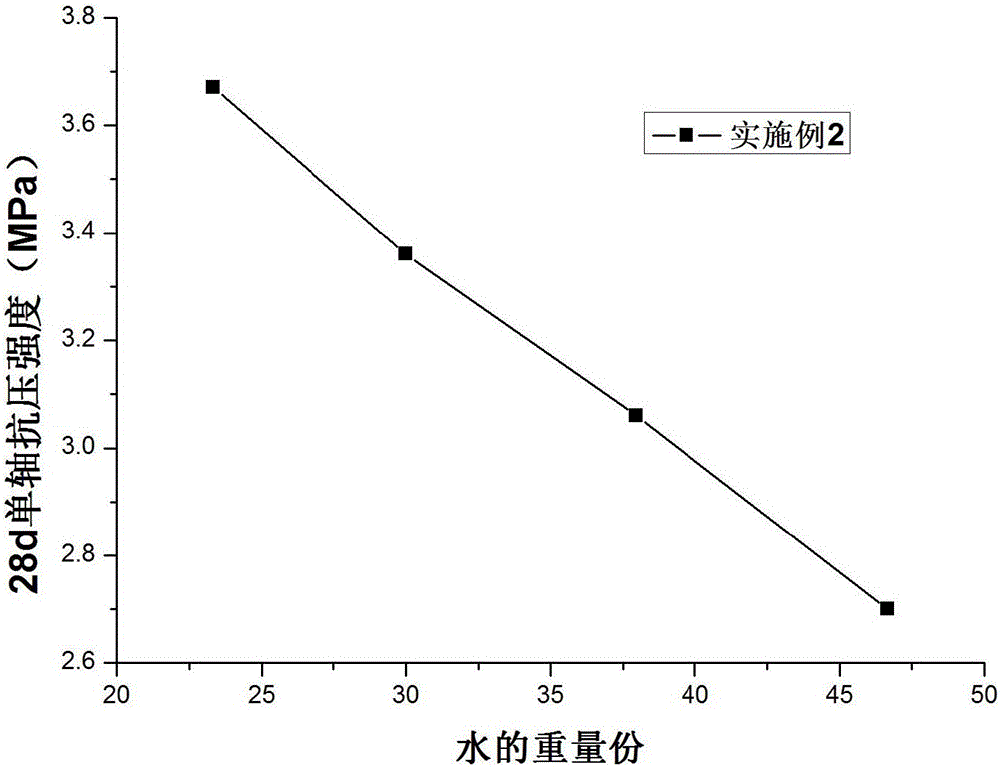

[0051] Embodiment 2: In this embodiment, the cemented filling material used in mines mainly consists of the following parts by weight (moderate strength):

[0052]

[0053] The amount of flocculant added is 10g / t, and the mass concentration of flocculant aqueous solution is 0.1%.

[0054] The preparation method of the filling slurry is the same as that in Example 1, and the prepared filling body enters the gob through the delivery pipeline.

[0055] After the filling body obtained in Example 2 was cured in a curing box at a temperature of 18°C and a humidity of 85% for 7d, 14d and 28d, the measured uniaxial compressive strength is shown in Table 2 below.

[0056] Table 2:

[0057]

[0058] After 28 days of curing, the strength of the filling material ranges from 2.7 to 3.67MPa, which meets the strength requirements of the filling material and is suitable for mine filling with moderate strength requirements.

Embodiment 3

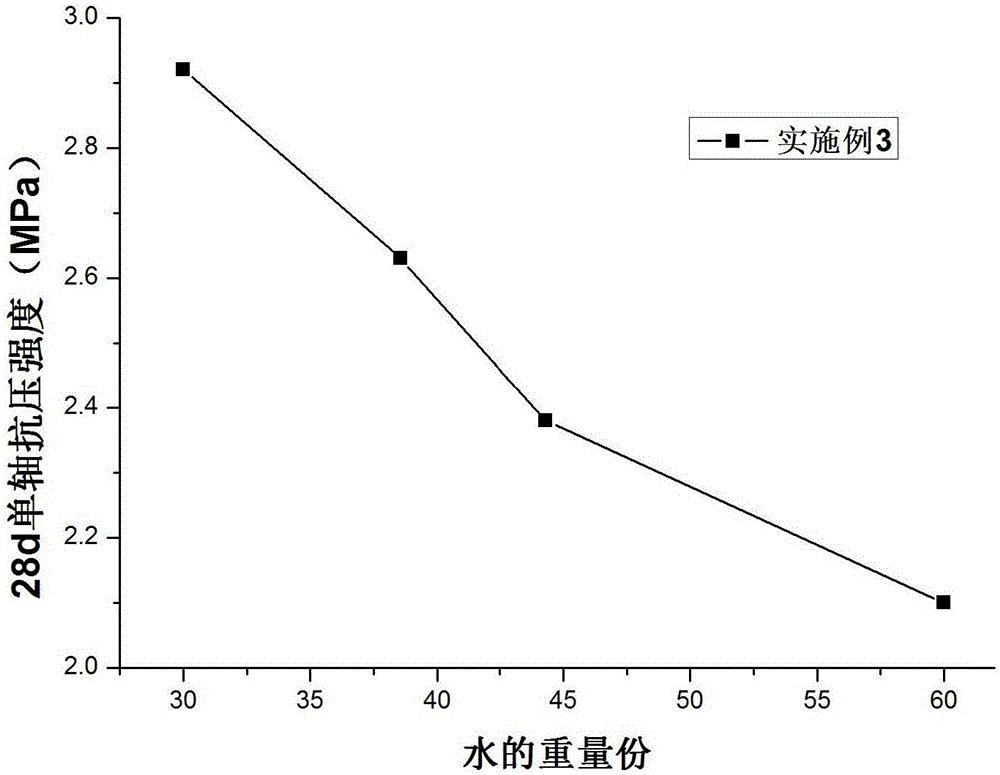

[0060] In this embodiment, the cemented filling material used in mines mainly consists of the following parts by weight (moderate strength):

[0061]

[0062] The amount of flocculant added is 10g / t, and the mass concentration of flocculant aqueous solution is 0.1%.

[0063] The preparation method of the filling body is the same as that in Example 1, and the prepared filling body enters the gob through the delivery pipeline.

[0064] After the filling body obtained in Example 3 was cured in a curing box at a temperature of 18°C and a humidity of 85% for 7d, 14d and 28d, the measured uniaxial compressive strength is shown in Table 3 below.

[0065] table 3:

[0066]

[0067] After 28 days of curing, the strength of the filling material ranges from 2.1 to 2.92MPa, which meets the strength requirements of the filling material and is suitable for mine filling with low strength requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com