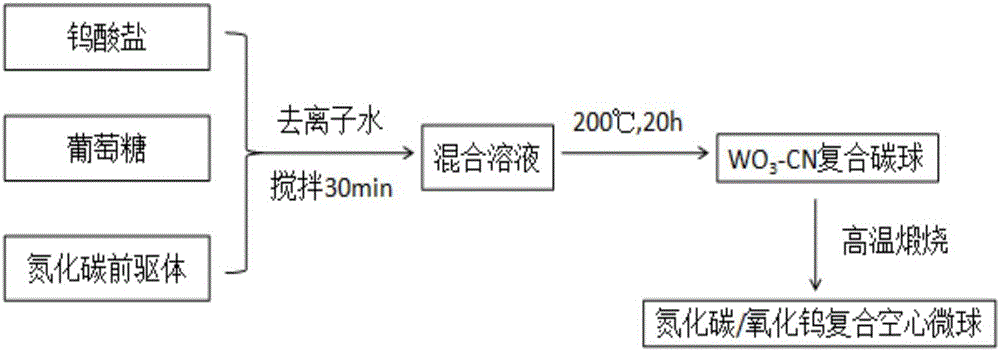

Carbon nitride/tungsten oxide composite hollow microsphere and preparation method thereof

A technology of hollow microspheres and carbon nitride, applied in nitrogen compounds, chemical instruments and methods, nitrogen and non-metallic compounds, etc., can solve the complex preparation process of tungsten oxide spheres, small specific surface area of composite materials, and weak visible light response ability and other problems, to achieve the effect of improving absorption and utilization capacity, improving photoelectric performance, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

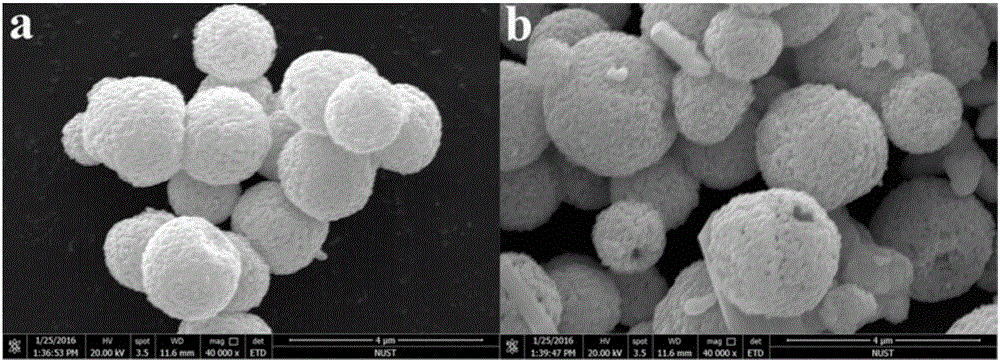

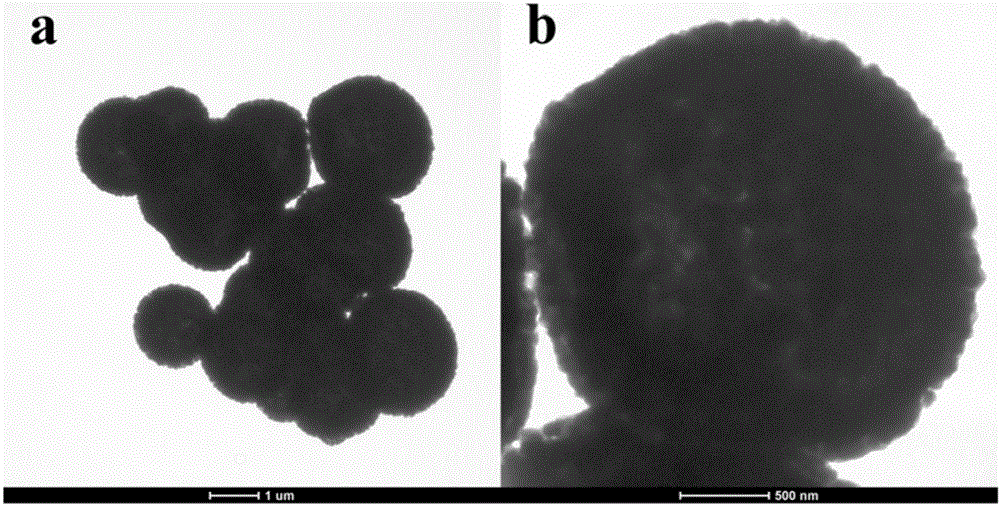

[0026] 0.330 g (1.0 mmol) of Na 2 WO 4 ·2H 2 O, 4.504g (25mmol) glucose and 0.336g (8mmol) cyanamide were dissolved in 50ml deionized water, sonicated and stirred for 30min to form a homogeneous solution. The above-mentioned mixed solution was transferred to a stainless steel hydrothermal kettle, heated to 200°C at 2°C / min in a muffle furnace, and kept for 20 hours. After natural cooling, centrifugation, repeated washing with distilled water and absolute ethanol for 3 times, and vacuum drying at 60 °C to obtain WO 3 -CN composite carbon ball. The obtained composite carbon spheres were heated to 500 ℃ at 2 ℃ / min in a tube furnace, calcined for 2 hours, and cooled naturally to finally obtain carbon nitride / tungsten oxide composite hollow microspheres.

Embodiment 2

[0028] 0.330 g (1.0 mmol) of Na 2 WO 4 ·2H 2 O, 4.504g (25mmol) glucose and 0.252g (2mmol) melamine were dissolved in 50ml deionized water, ultrasonicated and stirred for 30min to form a homogeneous solution. The above-mentioned mixed solution was transferred to a stainless steel hydrothermal kettle, heated to 200°C at 2°C / min in a muffle furnace, and kept for 20 hours. After natural cooling, centrifugation, repeated washing with distilled water and absolute ethanol for 5 times, and vacuum drying at 60 °C to obtain WO 3 -CN composite carbon ball. The obtained composite carbon spheres were heated to 500 °C at 5 °C / min in a tube furnace, calcined for 2 hours, and naturally cooled to finally obtain carbon nitride / tungsten oxide composite hollow microspheres.

Embodiment 3

[0030] 0.330 g (1.0 mmol) of Na 2 WO 4 ·2H 2 O, 4.504g (25mmol) glucose and 0.481g (8mmol) urea were dissolved in 50ml deionized water, ultrasonicated and stirred for 30min to form a homogeneous solution. The above mixed solution was transferred to a stainless steel hydrothermal kettle, heated to 200°C at 2°C / min in a muffle furnace, and kept for 24 hours. After natural cooling, centrifugation, repeated washing with distilled water and absolute ethanol for 4 times, and vacuum drying at 60 °C to obtain WO 3 -CN composite carbon ball. The obtained composite carbon spheres were heated to 550 °C at 5 °C / min in a tube furnace, calcined for 5 hours, and naturally cooled to finally obtain carbon nitride / tungsten oxide composite hollow microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com