Control method and control system for numerically-controlled sliding table saw

A control method and control system technology, applied in the direction of digital control, electric program control, circular saw, etc., can solve the problems of poor positioning accuracy and low production efficiency by ruler, so as to improve sawing efficiency, save labor costs, save human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

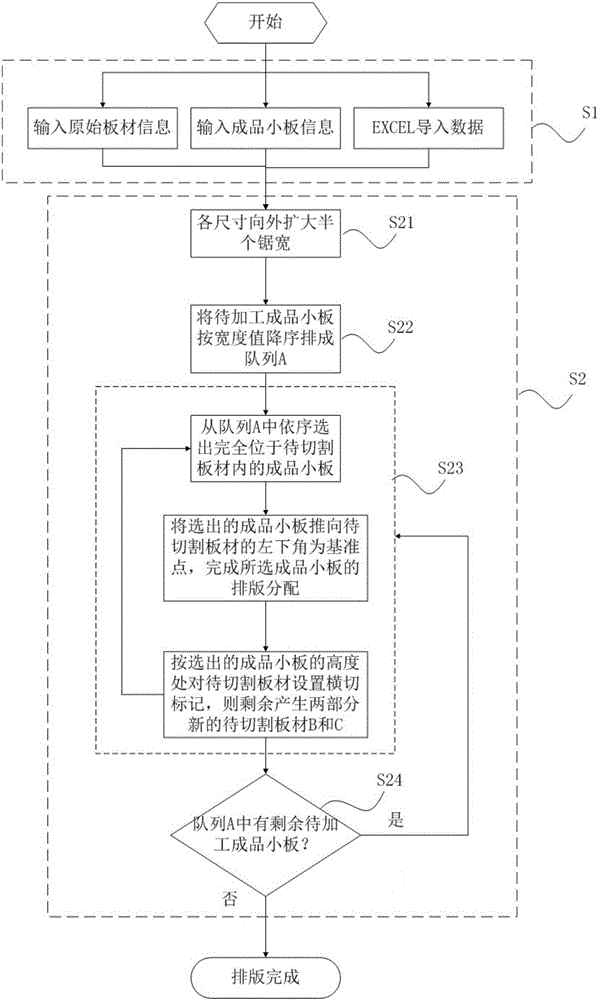

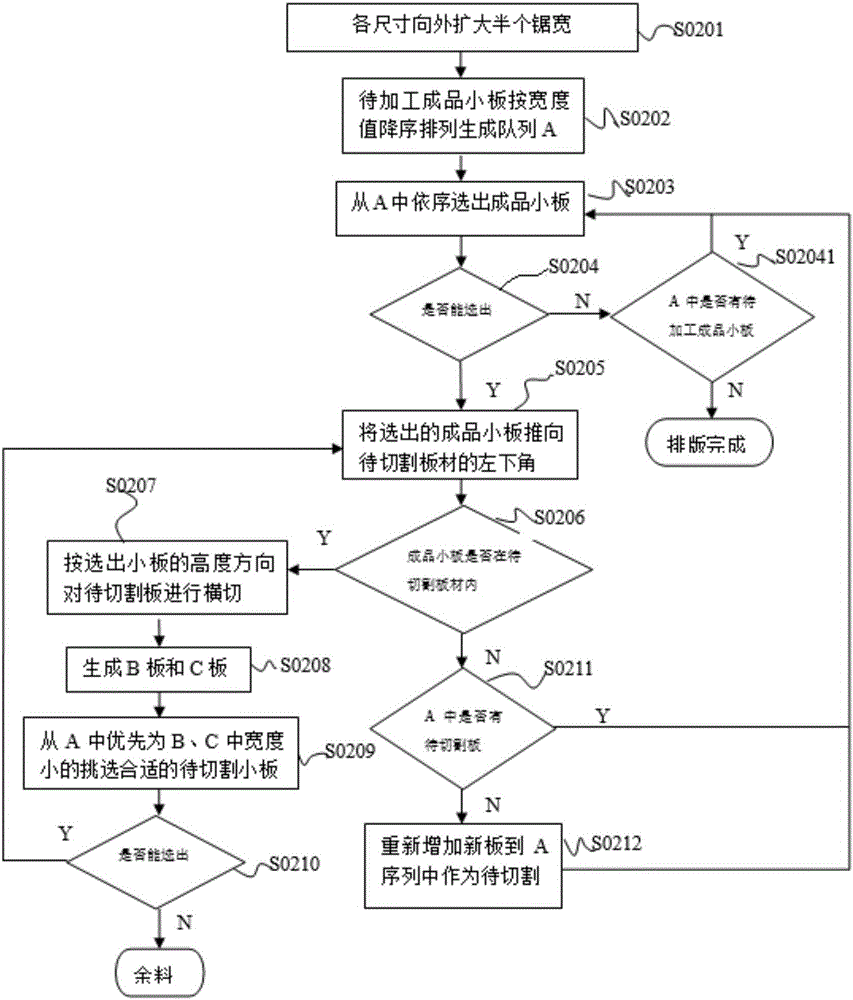

[0043] Embodiment 1. This embodiment proposes a numerical control sliding table saw optimized typesetting method to solve defects such as low sawing precision, low efficiency, and high cost caused by manual typesetting. Refer to figure 1 , which includes the following steps:

[0044]S1. Obtain the parameter information of the original plate and each finished small plate. The parameter information includes information such as the length and width of each plate. The method obtained in this step can be input manually or by importing data through excel;

[0045] S2. Optimize typesetting according to the above parameter information, the specific steps are as follows:

[0046] S21, expanding the dimensions of each side of each original board and all finished small boards to be processed outward by half the sawing width, mainly to improve sawing accuracy;

[0047] S22. Arranging all the finished small boards to be processed into a queue A according to the width value from large to s...

Embodiment 2

[0066] Embodiment 2. This embodiment proposes an optimized typesetting system for a CNC sliding table saw. Refer to image 3 , mainly includes: plate information acquisition module, used to obtain the parameter information of the plate to be cut and each finished small plate; optimized layout module, to obtain the layout optimization scheme of the plate to be cut and the cutting file after optimized layout; also includes the information module, used to Save system status and information generated during system operation, such as cutting plan, cutting file and other information.

[0067] In this embodiment, in order to obtain an optimized typesetting solution to cut the plate to be cut, the optimized typesetting module includes:

[0068] The plate information processing module is used to expand the rectangular dimensions of each original plate and all finished small plates to be processed outward by half the saw width;

[0069] Finished small board width arrangement module is ...

Embodiment 3

[0073] Embodiment 3, this embodiment proposes an automatic cutting method of a CNC sliding table saw, which realizes the purpose of automatic cutting of plates by the sliding table saw by automatically driving and positioning the ruler, refer to Figure 4 , including the following steps:

[0074] S1', load the cutting file, there are many ways to load the cutting file here, you can read the external cutting file by scanning the QR code or call the automatic cutting file from the hard disk, this embodiment does not limit the loading of the cutting file the manner and type of

[0075] S2'. Obtain the cutting position, and place the plate to be cut according to the dynamic prompt information during the cutting process. The dynamic prompt information includes the size of the plate to be cut and the plate direction indication information, etc., and place the plate on the sliding table saw according to the instructions;

[0076] S3', driving and positioning the ruler to the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com