Flow rate progressively decreased multi-drum type material washing and separating method

A separation method, a drum-type technology, applied in wet separation, solid separation, chemical instruments and methods, etc., can solve the problem of inability to meet continuous, large-scale production, large floor space and space, affecting continuous production. problems such as stability, to achieve the effect of accurate and convenient observation, good water flow velocity, and saving production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

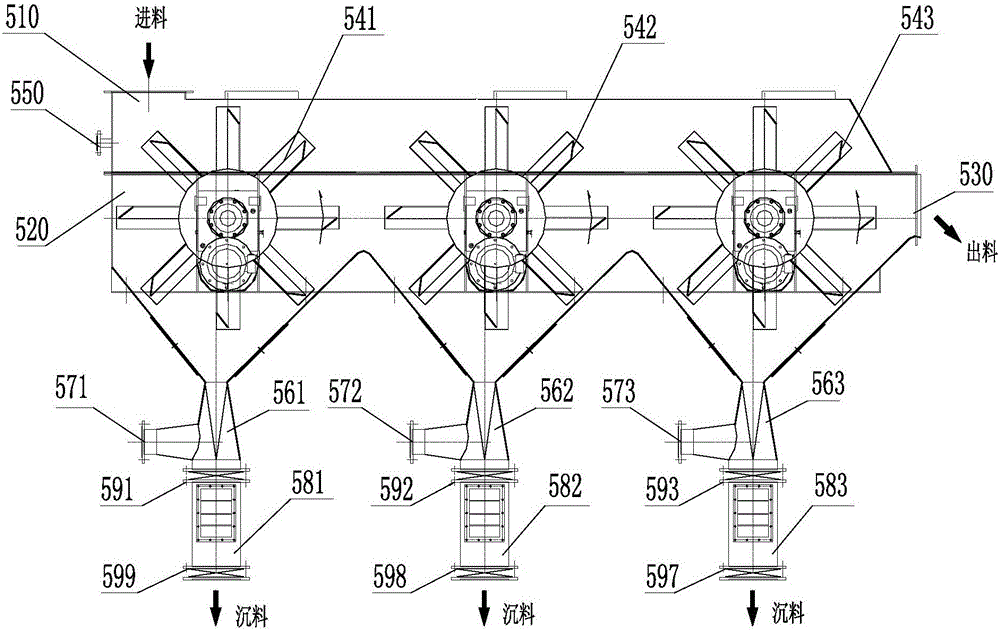

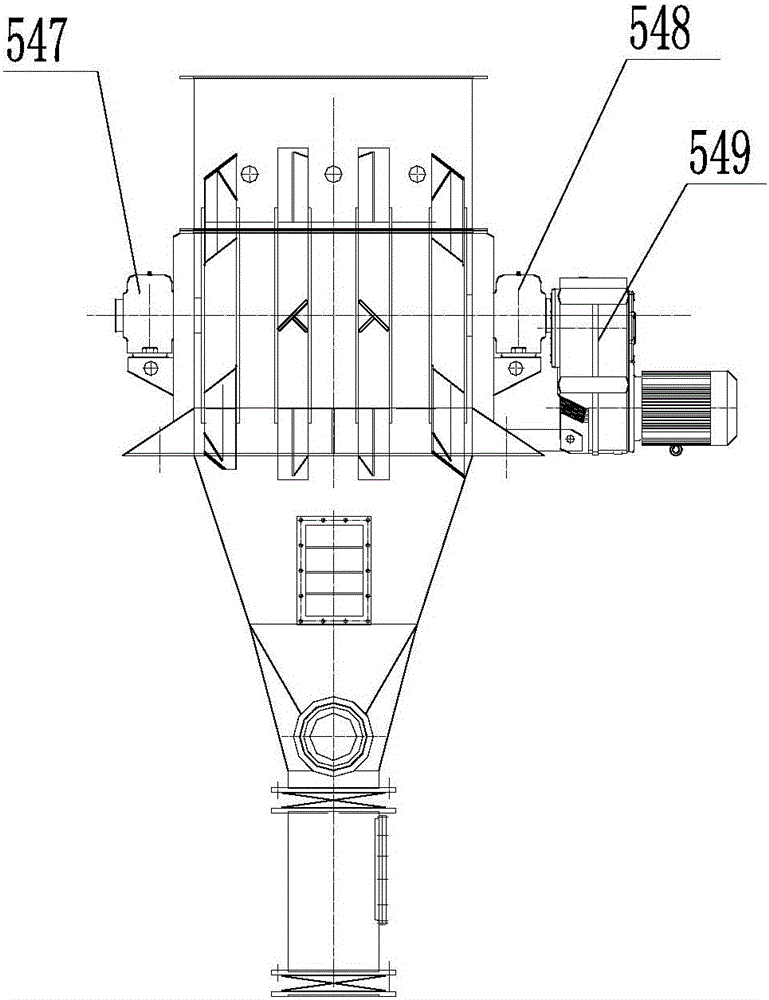

[0040] Device Example 1: The structure diagram of the multi-drum washing and separating device in this embodiment is as follows figure 1 As shown, it includes a body 520, the upper part of one end of the body 520 is provided with a feed port 510, and the other end is provided with a discharge port 530, and a washing chamber is provided in the body 520, and a drum is provided in the washing chamber. Three drums are arranged in sequence between the feed port and the discharge port, namely the first drum 541, the second drum 542 and the third drum 543;

[0041] The shape of the bottom of the body 520 is three inverted truncated cones juxtaposed, and the positions of the inverted truncated cones correspond to the positions of the drums one by one, and are located below the corresponding drum positions; the inverted truncated cones are the upper mouth and the lower mouth. Small frustoconical.

[0042] One end of the body 520 adjacent to the feed port 510 is provided with an upper ...

Embodiment 2

[0046] Device Embodiment 2: The structure is basically the same as that of Device Embodiment 1, and the similarities will not be described again. The difference is:

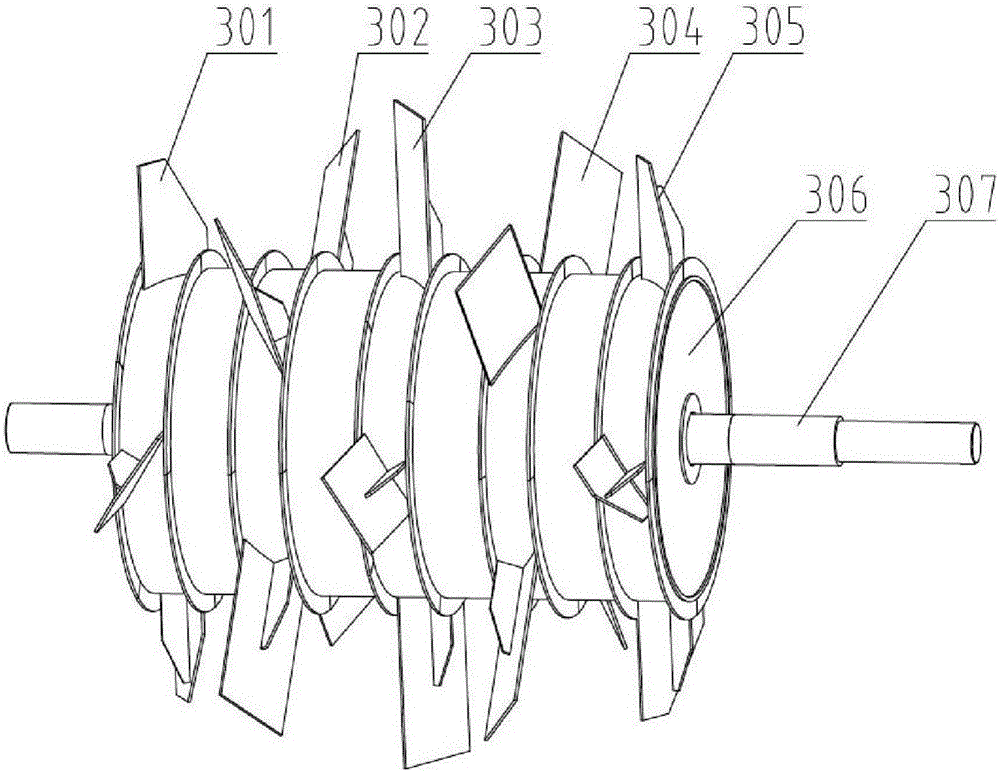

[0047] Five drums are arranged in turn between the feed inlet and the discharge port; two sets of blades are arranged on the runner of the same drum, and the two sets of blades have the same feeding direction along the tangential direction of the runner. The direction of material shifting in the axial direction of the wheel is relative.

[0048] Each of the lower water inlets is correspondingly equipped with a flow rate control device, each of the pipes is correspondingly equipped with a flow meter, and each of the upper discharge valves and the corresponding lower discharge valves are automatic valves that open and close alternately at intervals .

[0049] Embodiment 1 is a preferred embodiment of the multi-drum washing and separating device of the present invention.

Embodiment 3

[0050] Method embodiment 3: this is the embodiment of multi-drum type material washing separation method:

[0051] The mixed material is solid waste from paper mills, and its main components are polypropylene film-based waste plastic sheets and wet-strength paper sheets, that is, the first type of material is wet-strength paper sheets, and the second type of material is polypropylene film-type waste plastic materials. piece. Here, the multi-drum washing and separating device provided by the device embodiment 1 is used to wash and separate the solid waste in the paper mill: the linear speed of the outer circle of the three drums arranged in sequence between the feed port and the discharge port It is 1.2m / s, and the weight ratio of dry mixture material to washing water is 3:97, that is, the washing concentration is 3%.

[0052]The mixed material is fed into the washing chamber through the feed port of the multi-drum washing and separating device; while washing water is injected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com