BiOCl-TiO2/diatomite photocatalyst and preparation method thereof

A technology of photocatalyst and diatomite, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. It can solve problems such as difficult recovery, easy agglomeration of simple catalysts, and difficult operation of the reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

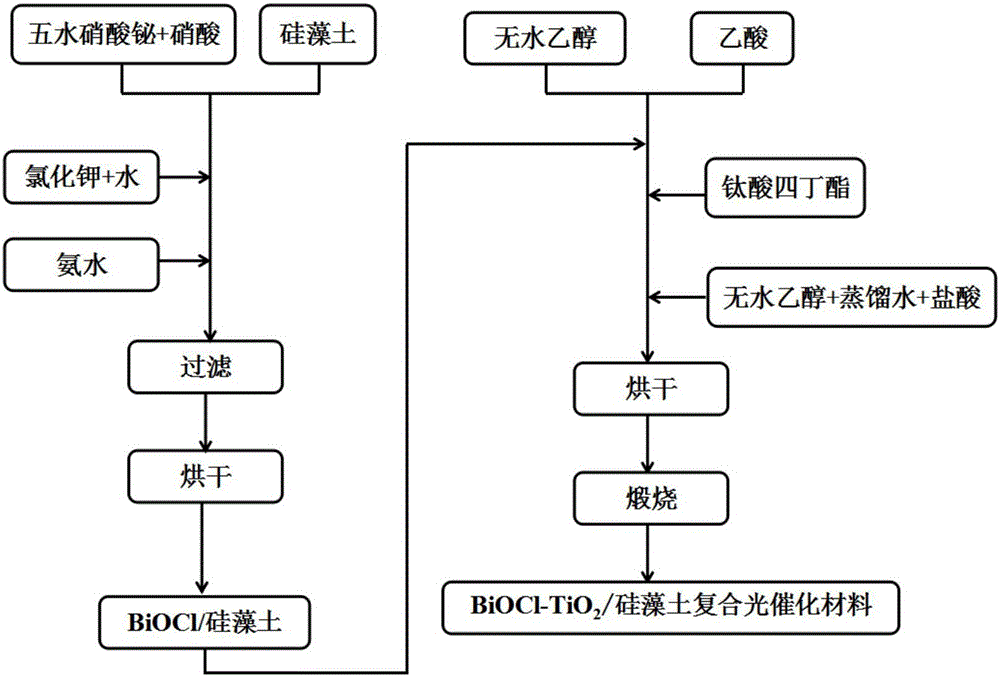

[0016] The specific implementation steps are as follows:

[0017] (1) Dissolve 0.52g of bismuth nitrate pentahydrate in 2mol / L nitric acid, add 1g of diatomaceous earth, stir evenly, weigh 0.10g of potassium chloride and dissolve in water, slowly add to the above pulp solution, adjust the solution with ammonia water pH=7, after stirring for 2 hours, the precipitate was filtered, washed, and dried at 105°C to obtain a BiOCl-diatomaceous earth sample.

[0018] (2) Take 14 mL of absolute ethanol, add the BiOCl-diatomite sample obtained in step (1), stir for 30 min to form a homogeneous suspension, add 1 mL of glacial acetic acid, stir for 30 min, add 3 mL of tetrabutyl titanate, and stir for 1 h A mixed solution of 6 mL of water and 6 mL of ethanol (adjusted to pH=2.0 with hydrochloric acid) was added to the above suspension, and peptized at room temperature for 12 h.

[0019] (3) The dried sample obtained in the above steps was calcined at 500° C. for 2 hours, and the heating r...

Embodiment 2

[0022] Same as step in embodiment 1, difference is: the add-on of bismuth nitrate pentahydrate is 0.78g in the step (1), and the add-on of potassium chloride is 0.15g; In the step (2), the source of titanium is changed into tetraiso The addition amount of titanium propoxide and titanium tetraisopropoxide is 2 mL; in step (3), the calcination temperature is 600° C., and the calcination time is 3 hours.

Embodiment 3

[0024] Identical with step in embodiment 1, difference is: the add-on of bismuth nitrate pentahydrate is 0.91g in the step (1), and chlorine source changes sodium chloride into, and the add-on of sodium chloride is 0.17g; Step (2 ) in an amount of tetrabutyl titanate added of 1.5 mL; in step (3), the calcination temperature was 700° C., and the calcination time was 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com