Device and process for improving regeneration efficiency of ceramic filtering plate for phosphate tailing

A ceramic filter plate, regeneration efficiency technology, applied in the direction of filtration separation, separation device, fixed filter element filter, etc., can solve the problem of high cost, reduce cleaning cost, improve cleaning efficiency, and eliminate the use of filter elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

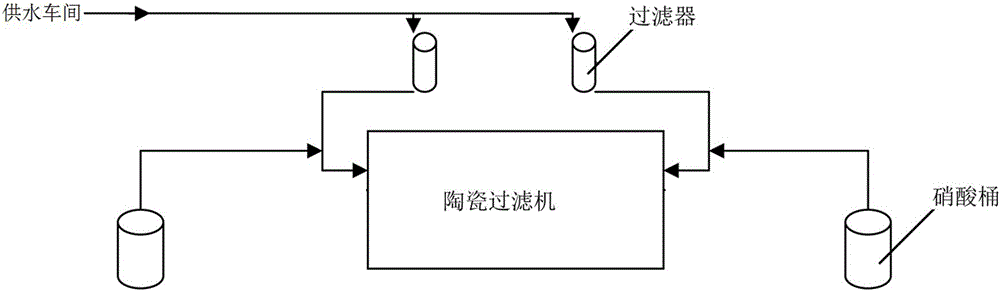

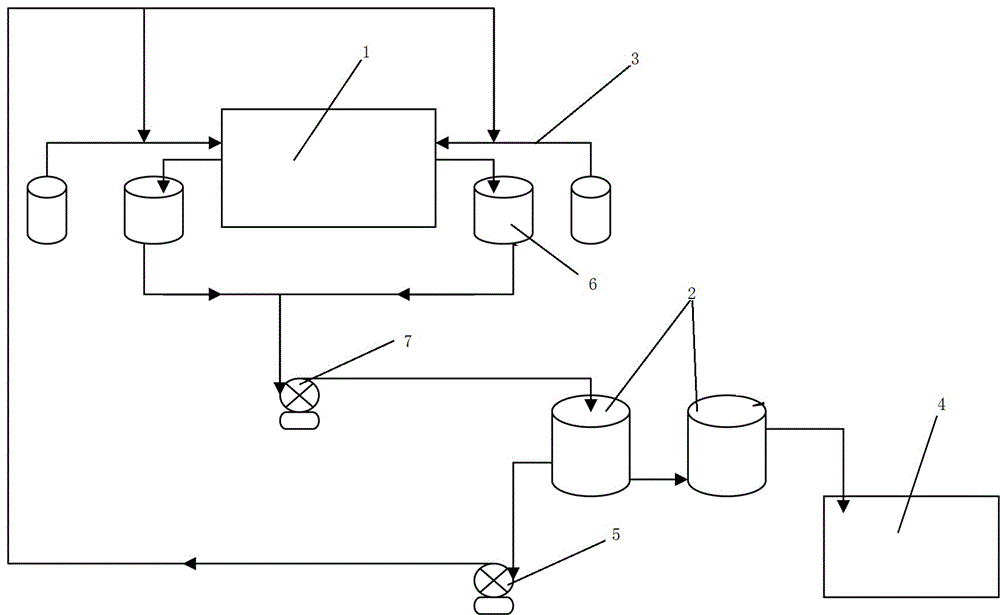

[0035] Use a ceramic filter to filter the tailings slurry after collophosite beneficiation. The mass concentration of the tailings slurry is 60%. The filtrate during filtration is collected in the filtrate recovery tank. After the filtrate recovery tank is full, the excess filtrate overflows to the circulating pool. After working for 8 hours, mix the filtrate from the filtrate recovery tank with nitric acid with a mass concentration of 50% to form a nitric acid cleaning solution with a mass concentration of 5%, and then add it to the entrance of the ceramic filter cleaning solution to clean the ceramic filter. The pressure of the liquid is 0.6 Mpa, and the sewage after cleaning is recovered and used in the tailings thickening device.

Embodiment 2

[0037] A ceramic filter is used to filter the tailings slurry after collophosite beneficiation. The mass concentration of the tailings slurry is 65%. The filtrate during filtration is collected in the filtrate recovery tank. After the filtrate recovery tank is full, the excess filtrate overflows to the circulating pool. After working for 6 hours, mix the filtrate of the filtrate recovery tank with nitric acid with a mass concentration of 50% to form a nitric acid cleaning solution with a mass concentration of 5%, and then add it to the entrance of the ceramic filter cleaning solution to clean the ceramic filter. The pressure of the liquid is 0.7 Mpa, and the sewage after cleaning is recovered and used in the tailings thickening device.

Embodiment 3

[0039]A ceramic filter is used to filter the tailings slurry after collophosite beneficiation. The mass concentration of the tailings slurry is 62%. The filtrate during filtration is collected in the filtrate recovery tank. After the filtrate recovery tank is full, the excess filtrate overflows to the circulating pool. After working for 7 hours, mix the filtrate from the filtrate recovery tank with nitric acid with a mass concentration of 50% to form a nitric acid cleaning solution with a mass concentration of 5%, and then add it to the entrance of the ceramic filter cleaning solution to clean the ceramic filter. The pressure of the liquid is 0.8 Mpa, and the sewage after cleaning is recovered and used in the tailings thickening device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com