Stepping piezoelectric drive motor

A technology of piezoelectric drive and piezoelectric vibrator, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., which can solve the problems of short motor life and high processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

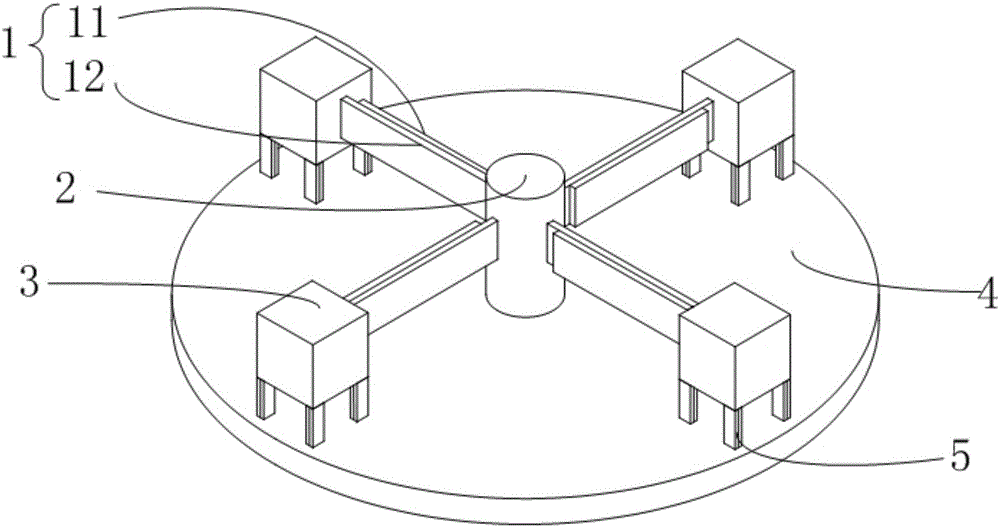

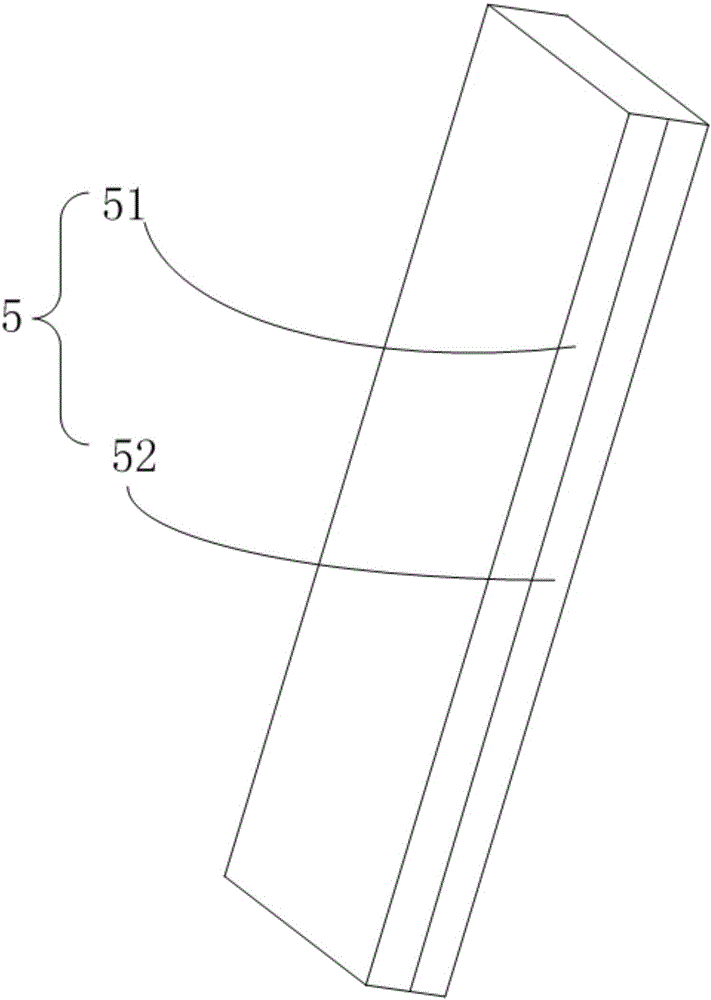

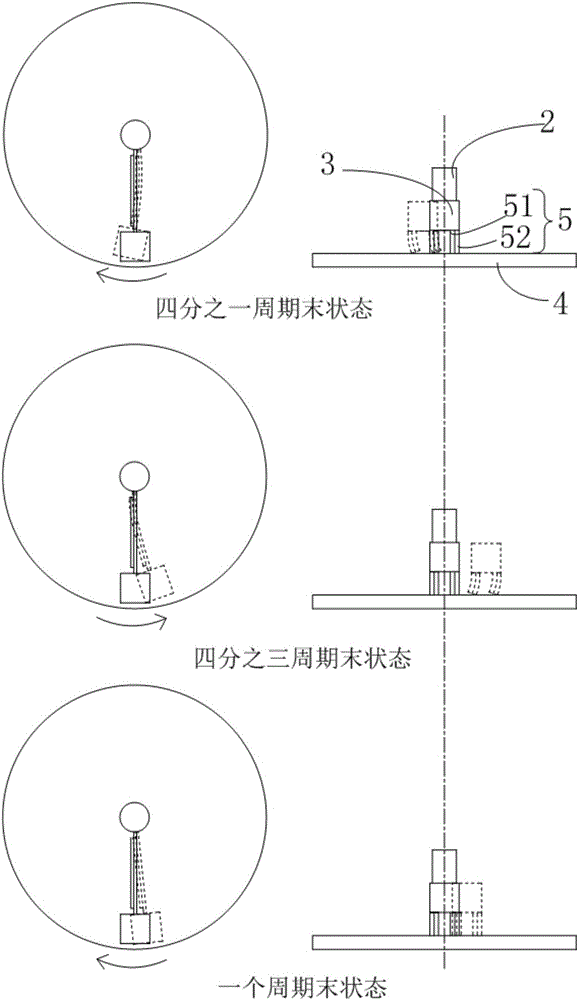

[0012] refer to figure 1 with figure 2 , including a piezoelectric vibrator 1, a rotating shaft 2, a mass 3 and a base 4, and is characterized in that it also includes a composite cantilever 5, wherein one ends of four piezoelectric vibrators 1 are fixedly connected to the rotating shaft 2, each The other end of each piezoelectric vibrator 1 is fixedly connected with a mass block 3; the composite cantilever 5 is a sheet-shaped structure and is composed of a high-friction elastic material 51 and a low-friction elastic material 52. The high-friction Both the elastic material 51 and the low-friction elastic material 52 have a thin sheet structure and the same size, the friction coefficient of the high-friction elastic material 51 is greater than that of the low-friction elastic material 52, and each of the mass blocks is 3 times Four composite cantilevers 5 are vertically arranged on the surface; the piezoelectric vibrator 1 is formed by bonding piezoelectric ceramics 11 and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com