30-slot 14-pole fractional-slot double-layer short-distance distribution winding 15-phase permanent magnet synchronous motor

A short-distance distribution and motor technology, which is applied to synchronous motors with stationary armatures and rotating magnets, electric components, magnetic circuit rotating parts, etc., can solve problems such as stator core vibration, reduce current amplitude, Reduced ferromagnetic saturation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

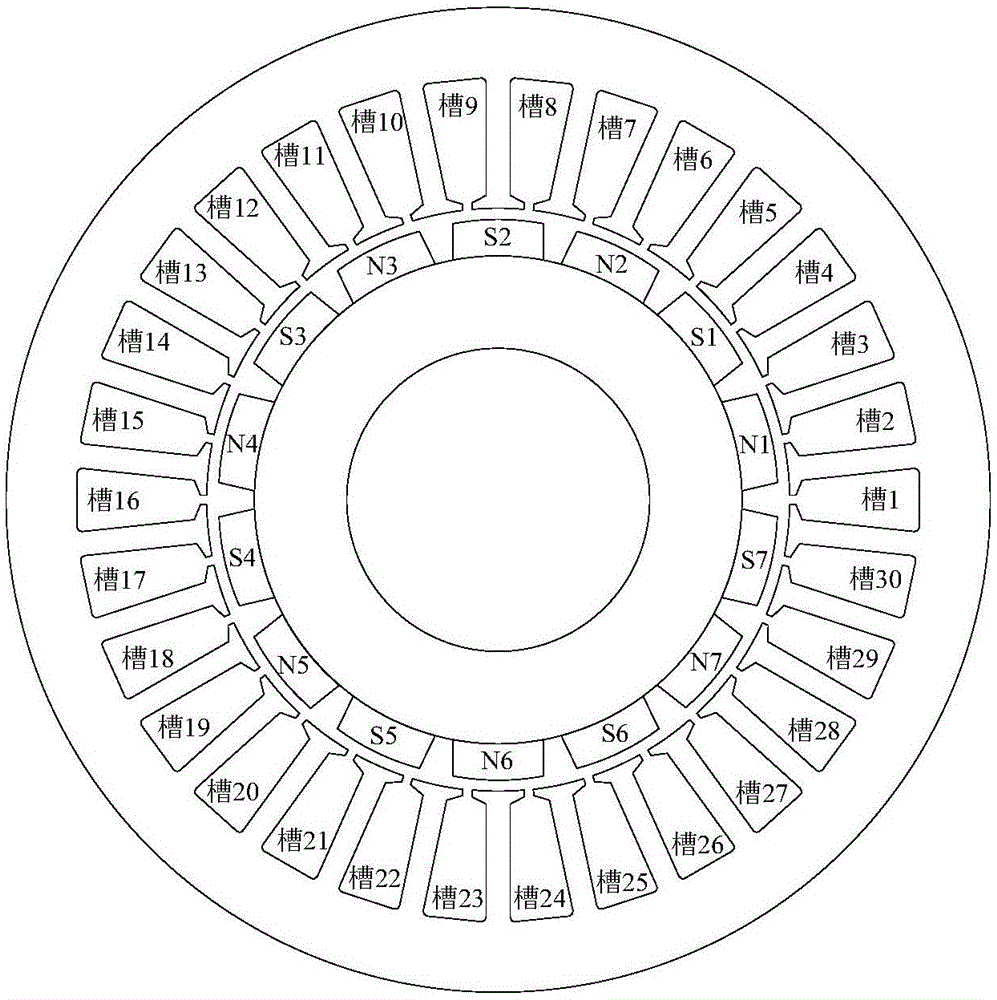

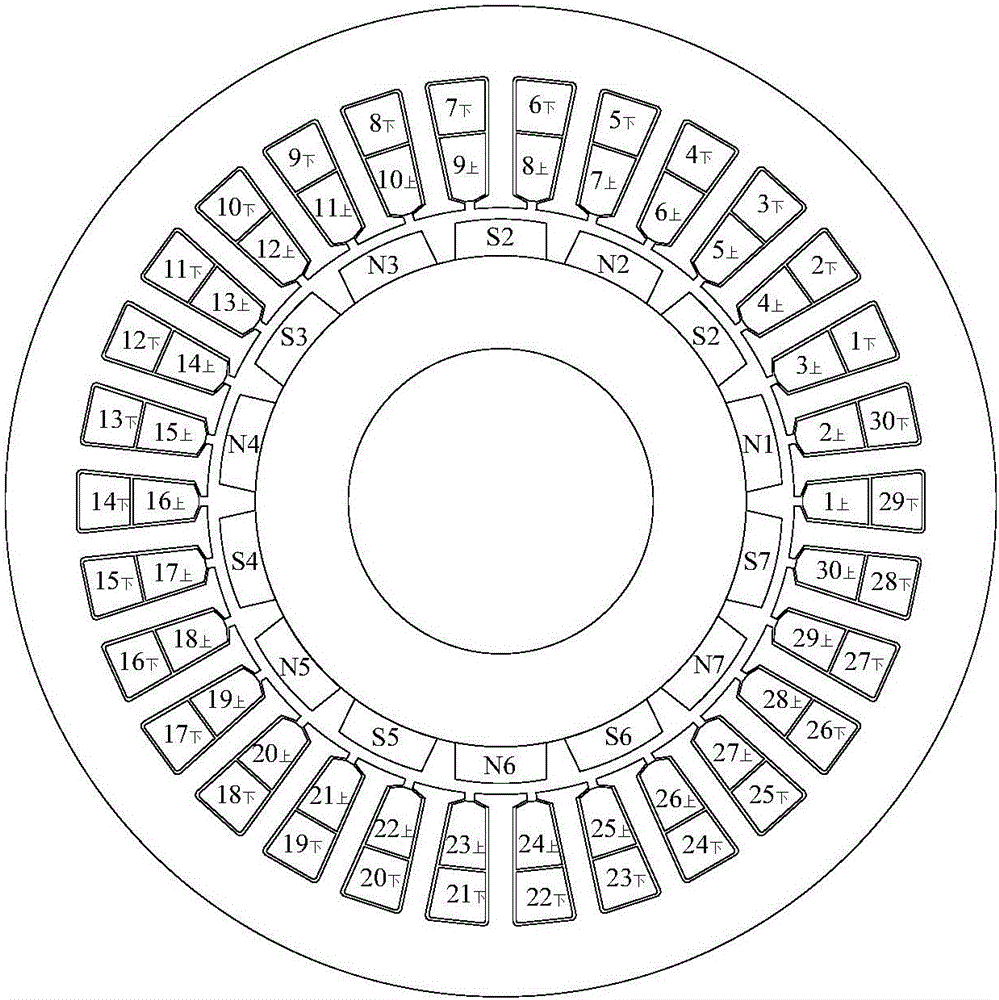

[0017] Such as figure 1 As shown, a 30-slot, 14-pole fractional slot double-layer short-distance distributed winding fifteen-phase permanent magnet synchronous motor proposed by the present invention includes the necessary frame, front end cover, rear end cover, bearings to form a complete motor. , junction box, stator core, stator winding, permanent magnet, rotor core, shaft and some necessary parts.

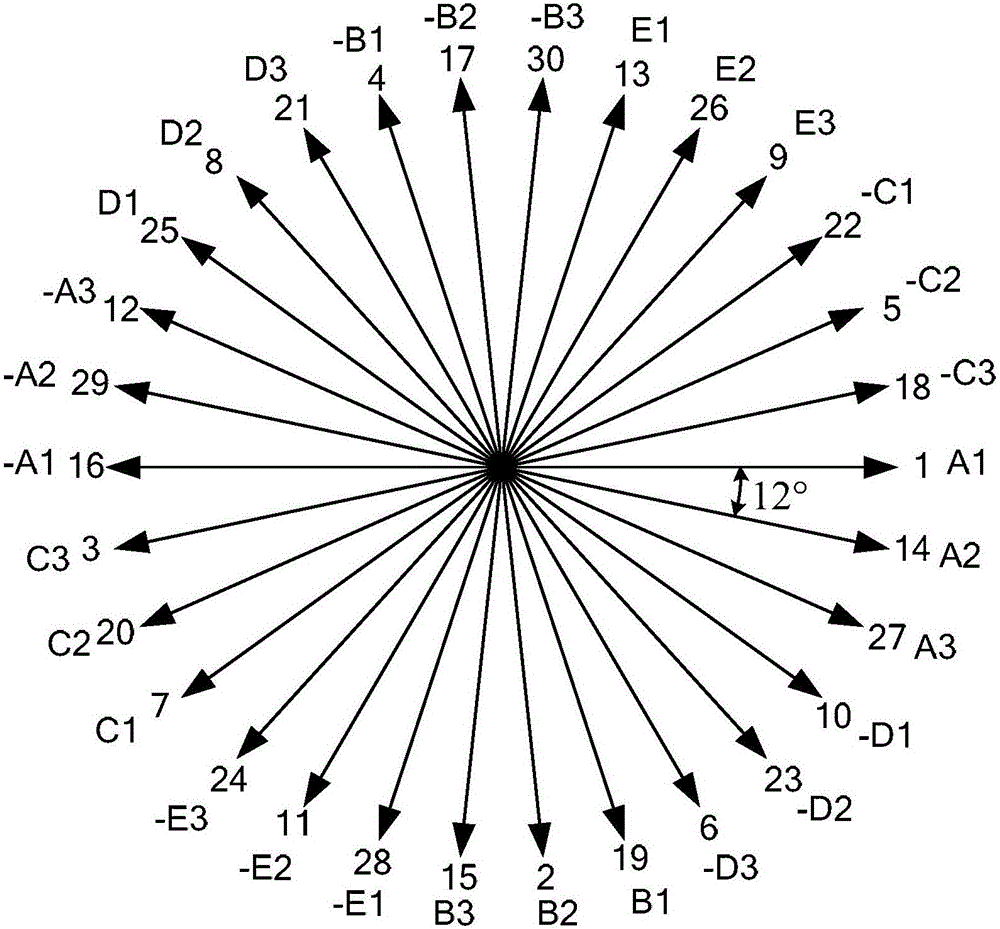

[0018] combine Figure 1 to Figure 10 The motor phase separation principle and winding connection method of the present invention are explained.

[0019] The 30-slot 14-pole fractional slot double-layer short-distance distribution winding 15-phase permanent magnet synchronous motor of the present invention has Z evenly arranged on the stator core. 0 = 30 teeth and slots, 7 pairs of permanent magnet poles are arranged on the rotor of the motor, and the 7 pairs of permanent magnet poles are evenly arranged on the circumference of the rotor according to the alternate arrangement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com