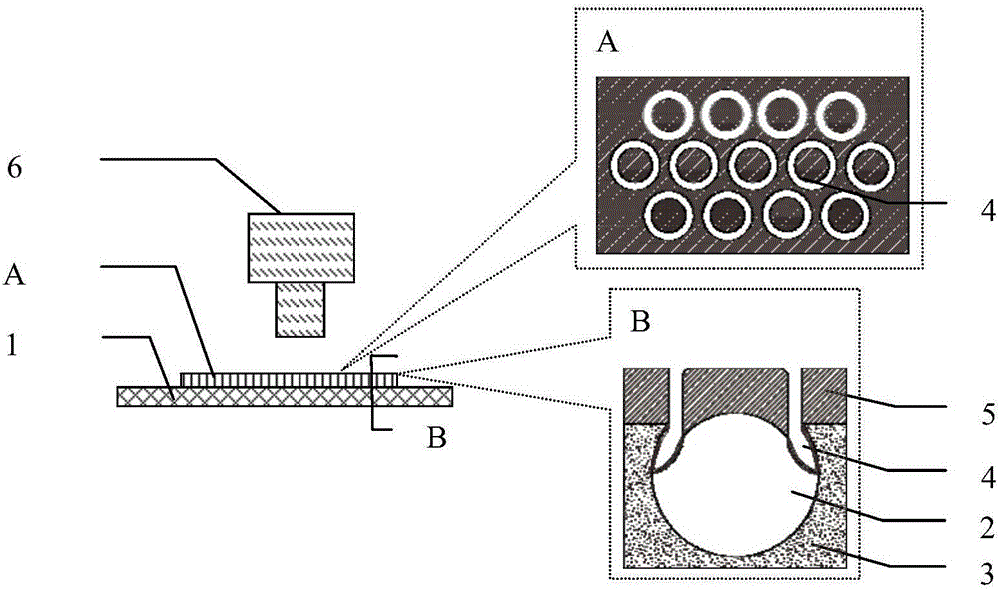

Nanometer annular cavity SERS substrate based on surface plasmon effect and manufacturing method thereof

A technology of surface plasmon and ring cavity, which is applied in the field of elemental spectrum analysis of plasmon effect, can solve the problems of complex structure and difficult processing of SERS substrate, and achieve good detection effect, good mechanical performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

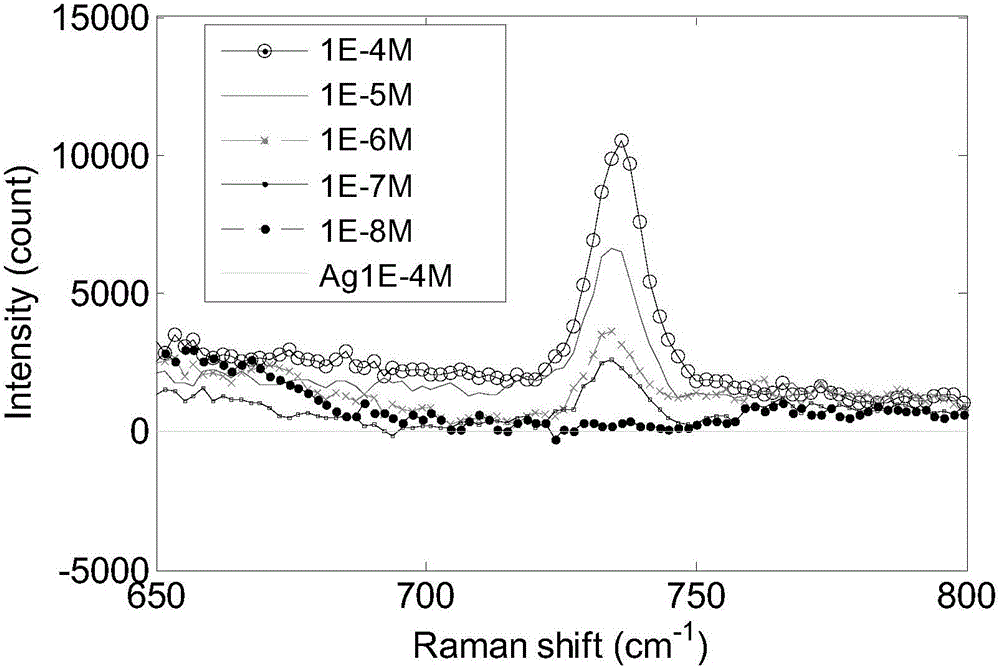

Examples

Embodiment 1

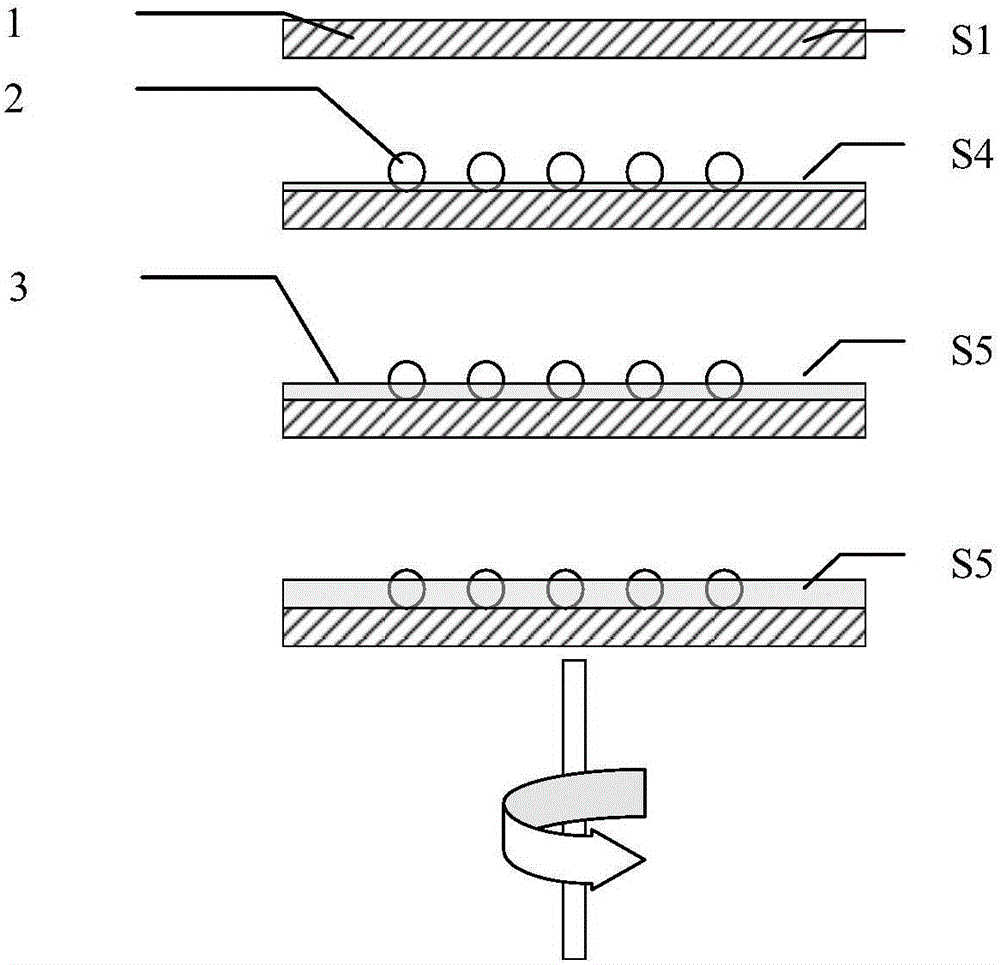

[0059] The steps of preparing the annular cavity SERS substrate are described in detail in conjunction with specific embodiments as follows:

[0060] a) Take a 2.5-inch silicon wafer, wash it with acetone (purity 99.7%), alcohol (purity 99.9%), deionized water (resistivity 18.2MΩ) ultrasonic (40W) for 10 minutes, and then use nitrogen gas (purity 99.7%) Blow dry; then process the silicon wafer with a plasma cleaner for 5 minutes;

[0061] b) Place the treated silicon wafer substrate on the tray of the homogenizer, and set the speed at 3000 rpm;

[0062] c) Configure SiO 2 Precursor solution of SiO 2 The mass of each substance in the precursor solution is: TEOS (98wt%)=1g, 0.1M / L HCl=1g, EtOH (100%)=1.5g, mix and stir for one hour for later use;

[0063] d) 20ml of colloidal microsphere solution configured with polystyrene (PS) microspheres, wherein the diameter of PS microspheres is 690nm, the diameter deviation rate is 0.2%, the volume percentage concentration is 0.05%, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com