Novel joint bearing wearing service lifetime testing clamp

A joint bearing and wear life technology, applied in the field of testing, can solve the problems of inconvenient installation and disassembly, support bearing slippage, etc., achieve the effect of reducing installation and disassembly strength, reducing load and torque, and improving the safety of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

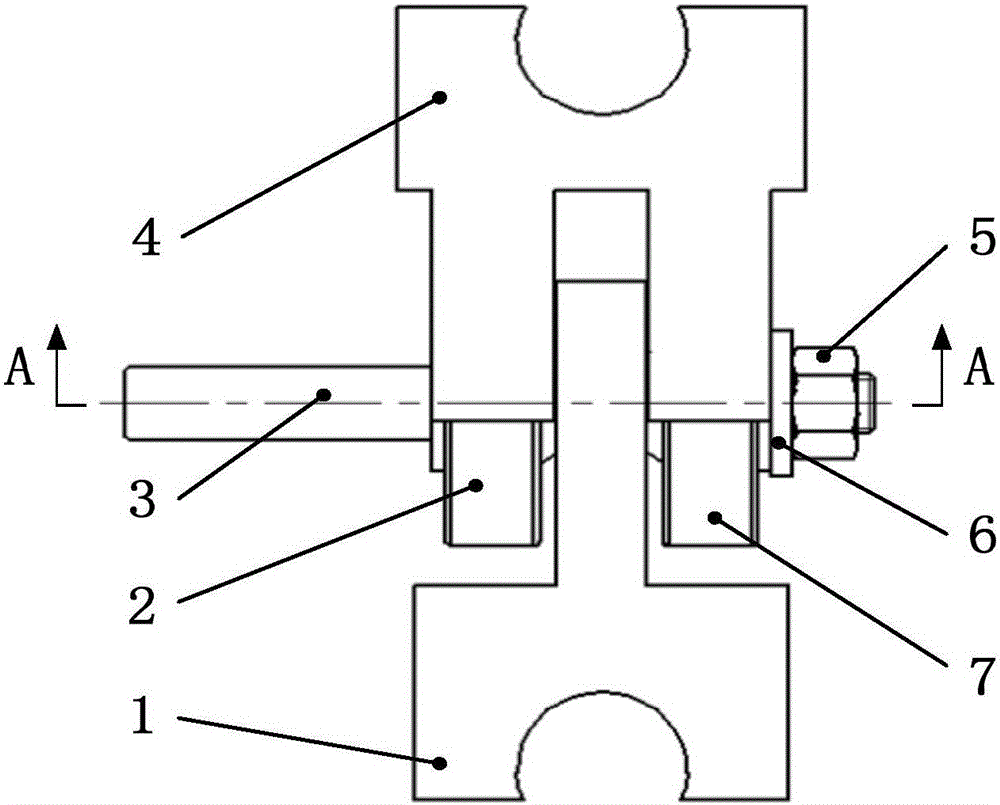

[0012] The new joint bearing swing wear life test fixture of the embodiment of the present invention, see Figure 1-3 , including a mandrel 3 without a keyway, clamp body I1, clamp body II4, left support bearing 2, right support bearing 7, left bush 8, right bush 12, left bearing gland 9, right bearing gland 11 , Baffle plate 6 and nut 5. The mandrel 3 passes through the left bush 8, the joint bearing 10 installed in the clamp body I1 and the right bush 12 in sequence. Contact, the left bearing gland 9 and the right bearing gland 11 together axially fix the outer ring of the joint bearing 10 in the clamp body I1; the left end of the mandrel 3 is connected to the drive system, and has a shoulder, which is on the left On the end face of the bush 8, the shaft head of the mandrel 3 has an external thread, and the nut 5 and the baffle plate 6 on the shaft head of the mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com