Cooking range generating steam by using waste heat

A technology of steam and stove, applied in the field of kitchen utensils, can solve the problems of insufficient utilization of heat, low utilization rate of waste heat, slow steam generation speed, etc., and achieves good promotion prospects, guarantees recovery and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

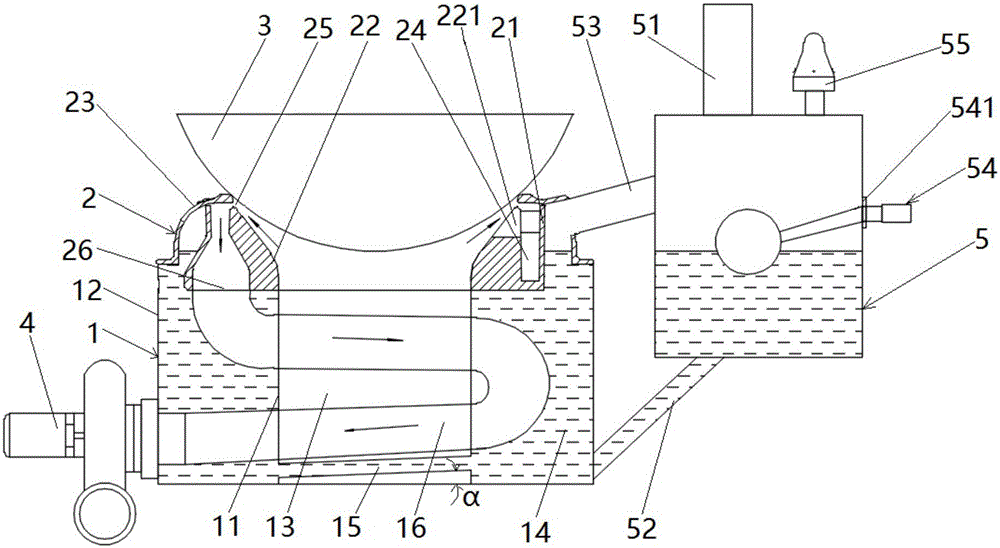

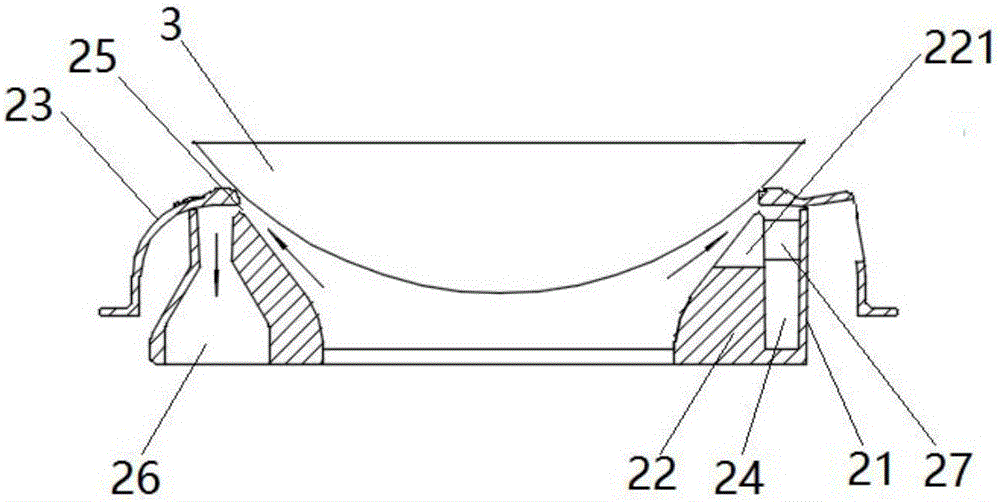

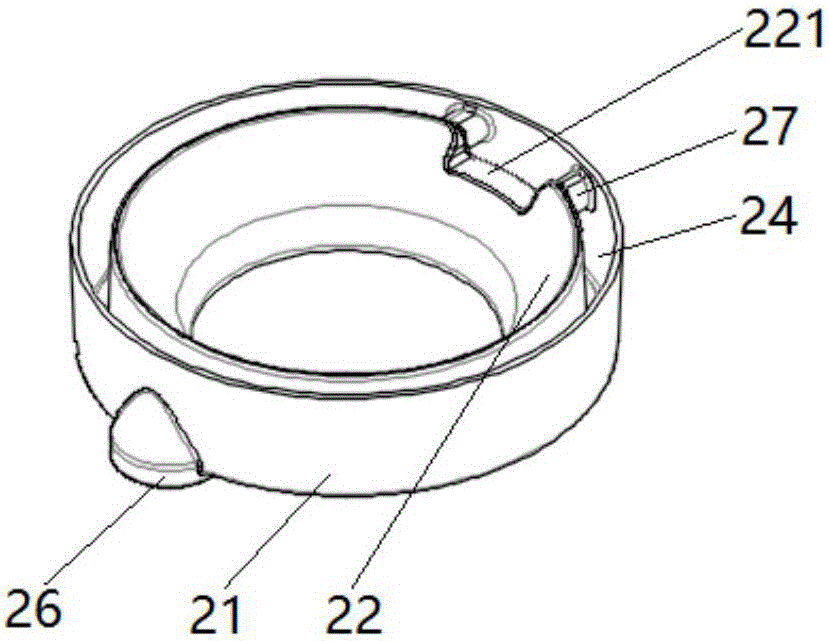

[0022] like figure 1 As shown, the cooking range of the present invention that utilizes waste heat to generate steam includes a furnace body 1 disposed above the furnace body 1 for supporting a burner 2 for cooking utensils 3, a water tank 5 for adding water 1 to the furnace body, and a Suction fan 4 for exhausting smoke. The furnace body 1 is composed of an inner furnace wall 11 and an outer furnace wall 12. The hollow area surrounded by the inner furnace wall 11 is a furnace hearth 13. The furnace head 2 includes an outer furnace ring 21 and an inner furnace ring 22. And the pot support ring 23, the bottom end of the inner furnace ring 22 is connected with the inner furnace wall 11, the bottom end of the pot support ring 23 is connected with the outer furnace wall 12, the inner furnace wall 11, the outer furnace wall The cavity fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com