Engine-driven water source compression type heat pump water vapor modulating machine

A compression heat pump, engine-driven technology, applied to engine components, combustion engines, machines/engines, etc., can solve the problem of reduced isentropic efficiency of water vapor compressors, increased system investment and power consumption, and power consumption of water source heat pumps increase and other problems, to avoid power generation, avoid power generation loss, and save investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

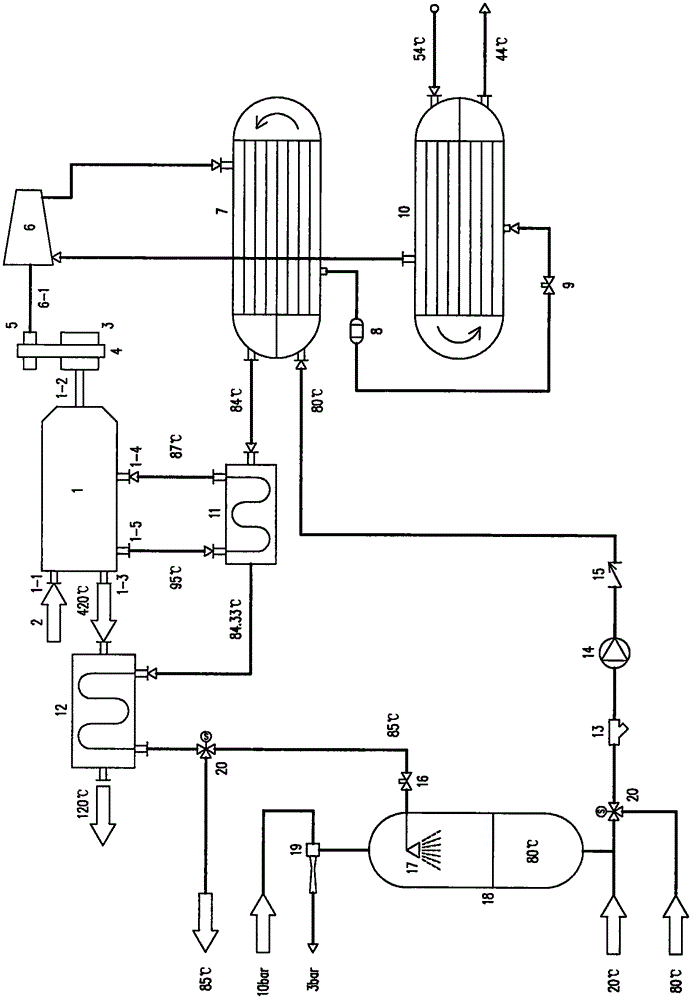

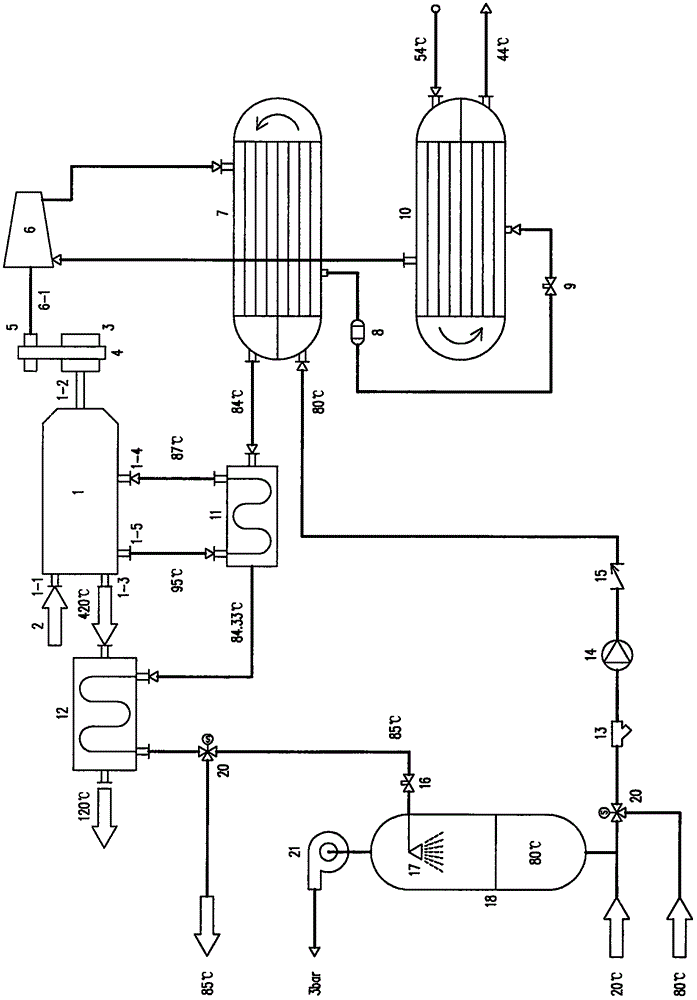

[0043] The embodiment of the engine-driven water source compression heat pump steam modulator proposed by the present invention is attached figure 1 As shown, the description is as follows: an engine 1 with an output shaft power of 1.20MW; a stainless steel air inlet 1-1 with a diameter of 32mm; a stainless steel drive shaft 1-2 with a length of 400mm and a diameter of 42mm; a stainless steel exhaust port 1-3 with a diameter of 32mm ;Cooling water inlet 1-4 of stainless steel sleeve cylinder with diameter 15mm; Cooling water outlet 1-5 of stainless steel sleeve cylinder with diameter 15mm; Natural gas fuel 2 with calorific value 8500kcal / kg; Stainless steel drive wheel 3 with diameter 400mm and width 60mm; Length 2m , a rubber belt 4 with a width of 50mm and a thickness of 5mm; a stainless steel driven wheel 5 with a diameter of 100mm and a width of 60mm; a compressor 6 with a suction capacity of 4860m3 / h; a stainless steel driven shaft 6-1 with a length of 400mm and a diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com