Oil well production fluid treatment system

A treatment system and production fluid technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of cost waste, affecting the efficiency of crude oil transportation, etc., and achieve the effect of ensuring continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

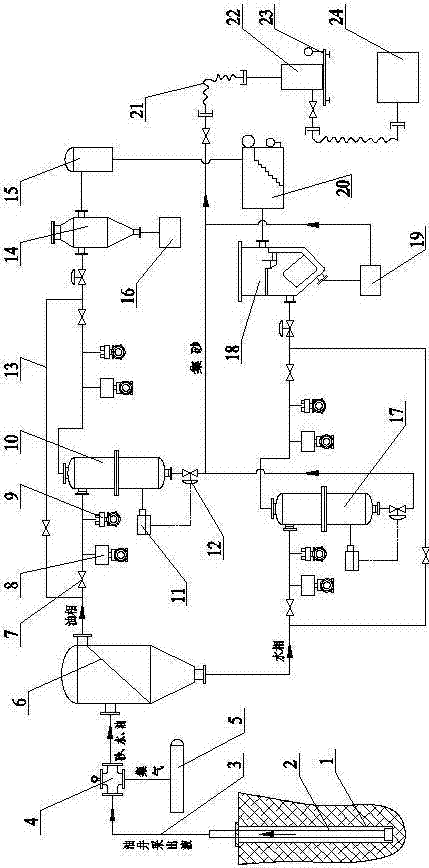

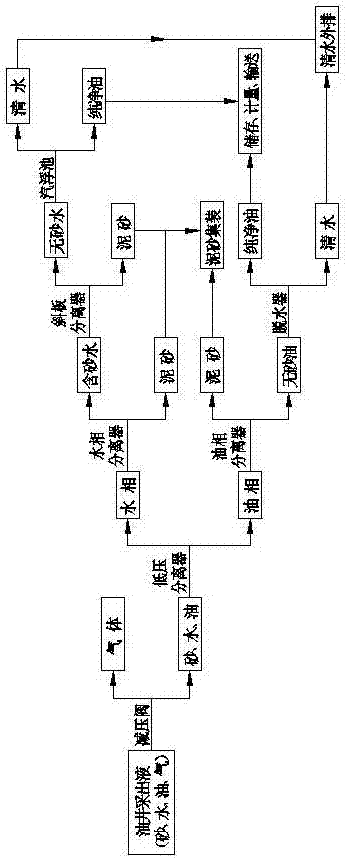

[0019] Such as figure 1 As shown, the oil well produced fluid treatment system mainly consists of oil well string 2, gathering and transportation pipeline 3, pressure reducing valve 4, gas collecting tank 5, low pressure separator 6, stop valve 7, pressure transmitter 8, and sand detector 9. Oil phase desander 10, material level switch 11, material level control valve 12, auxiliary pipeline 13, dehydrator 14, oil storage tank 15, water collection tank 16, water phase desander 17, inclined plate separator 18, Sand collection device 19, air flotation tank 20, hose 21, standard sand collection box 22, weighing system 23 and sewage collection tank 24, characterized in that: the top of oil well string 2 arranged in oil well 1 is connected to gathering pipeline 3 , the oil well production fluid through the oil well string 2 and the gathering pipeline 3 first enters the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com