Clothes dryer control method and clothes dryer

A control method and technology for a clothes dryer, applied in the field of clothes dryers, can solve the problems of reducing the condensation speed of water vapor, affecting the drying speed, reducing the operating frequency of the compressor, etc., so as to speed up the drying speed, reduce the energy consumption, reduce the effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

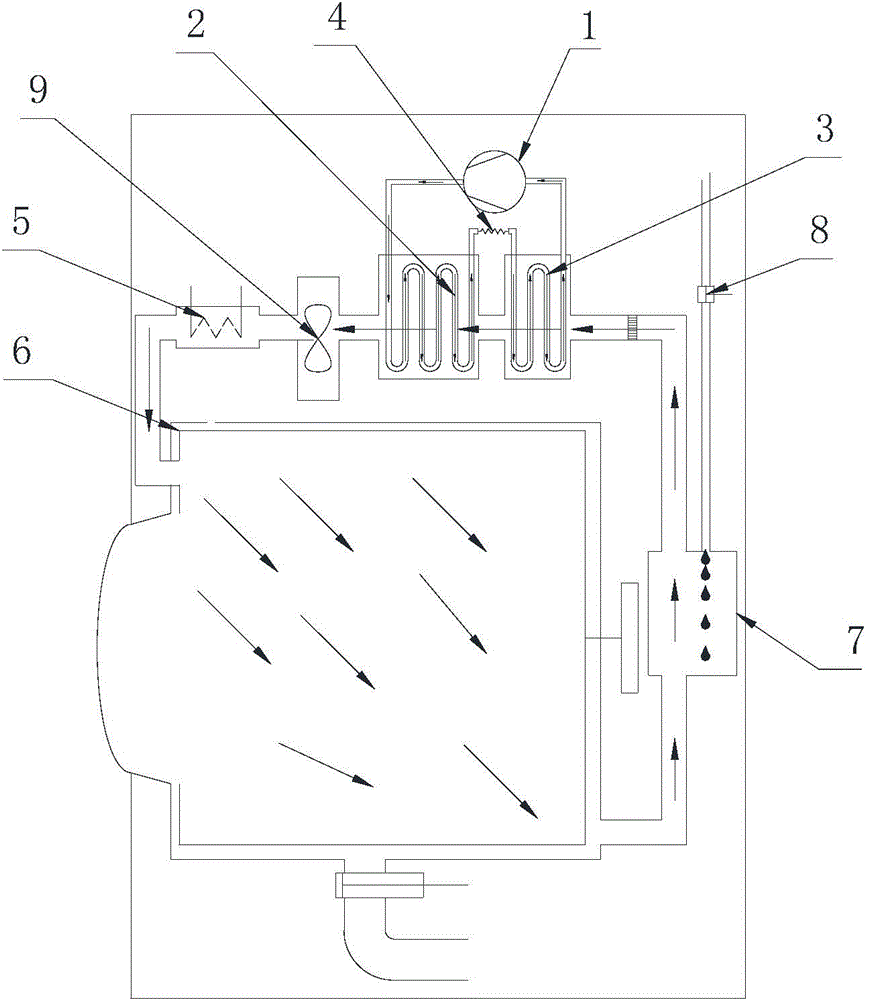

[0027] Such as figure 1 As shown, a clothes dryer according to the present invention includes a clothes drying drum 6, a heat pump system and an electric heating system, and the heat pump system includes a compressor 1, a condenser 2, an evaporator 3 and a throttling device 4 , the electric heating system is an electric heating pipe 5, and the clothes dryer also includes a water condenser 7, and the water condenser 7 is arranged between the air outlet of the drying drum 6 and the air inlet of the evaporator. The condenser 2 and the electric heating tube 5 of the heat pump system are heated at the same time to increase the temperature of the gas entering the cylinder, and the water condenser 7 can increase the condensation speed and improve the drying speed. A water valve 8 is arranged on the water condenser 7, and the opening and closing of the water condenser 7 is controlled by the opening and closing of the water valve 8.

[0028] Usually people think that adding the electr...

Embodiment 2

[0031] According to the method for controlling a clothes dryer in the present invention, the clothes dryer includes a clothes drying drum 6, a heat pump system and an electric heating system, the heat pump system includes a compressor 1, a condenser 2, an evaporator 3 and a throttling device 4, The electric heating system is an electric heating tube 5, and the condenser 2 and the electric heating tube 5 cooperate to heat so that the clothes dryer can have the following modes:

[0032] Fast mode: when drying clothes in the fast mode, the electric heating tube 5 is turned on, and the gas entering the drying drum 6 is controlled to be heated by the heat pump system condenser 2 first, then heated by the electric heating tube 5 and then enters the drying drum 6, and the heat pump system is close to the maximum When the load is on, the load of the heat pump system is reduced by means of auxiliary condensation before the heating pipe is disconnected. The auxiliary condensation method ...

Embodiment 3

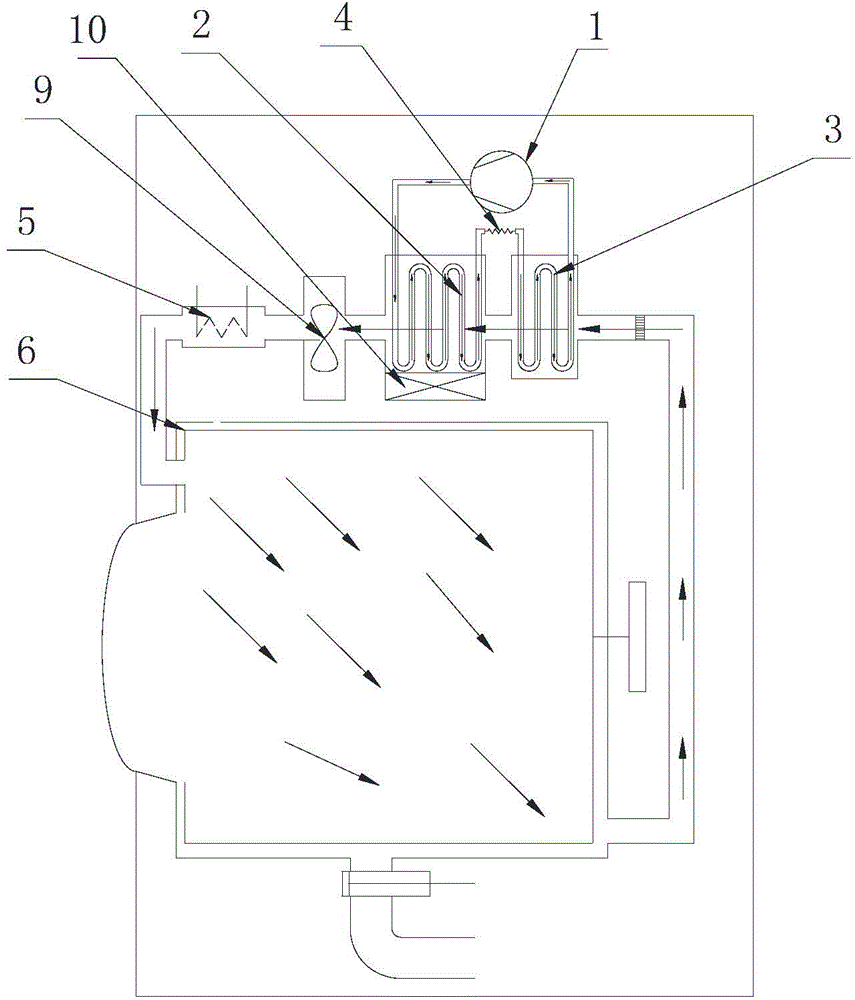

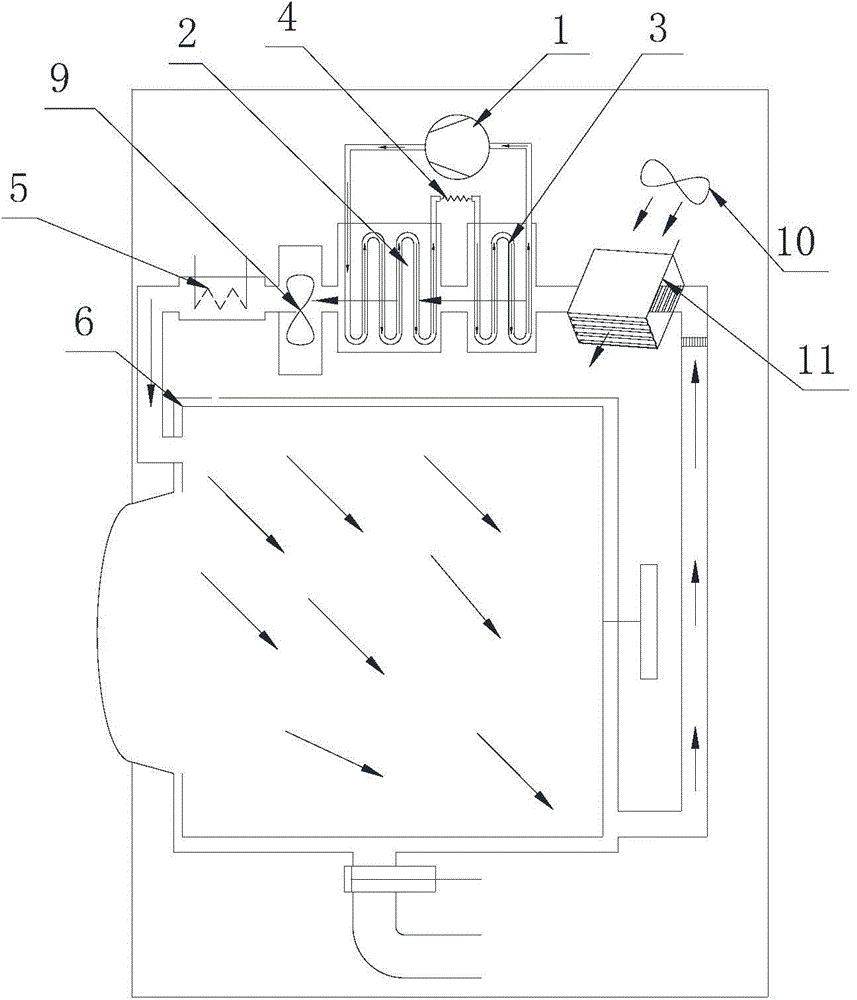

[0048] Such as figure 2 In this embodiment shown, the clothes dryer includes an auxiliary fan 10, and the way of assisting condensation is to use the auxiliary fan 10 to assist the heat dissipation of the condenser 2 of the heat pump system, reduce the temperature of the condenser, and reduce the load of the heat pump system. Other methods are the same as those in the embodiment Two same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com