A kind of micro-expansion coral sand concrete and its preparation method

A coral sand and micro-expansion technology, which is applied in the field of building materials, can solve the problems of fast drying shrinkage, low strength, and impact of water demand, and achieve the effects of ensuring volume stability, compensating and porosity, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

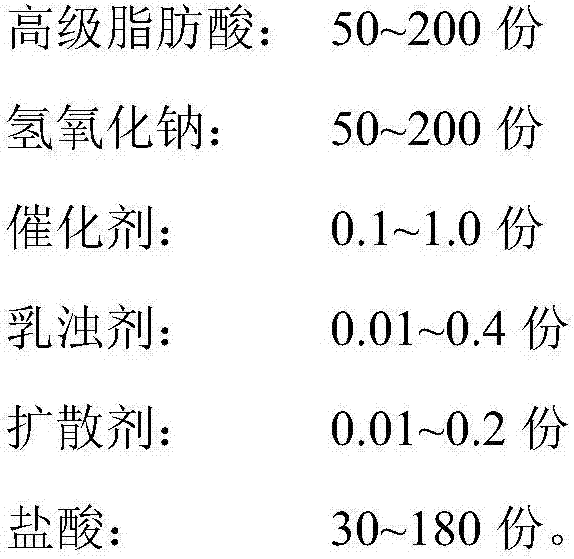

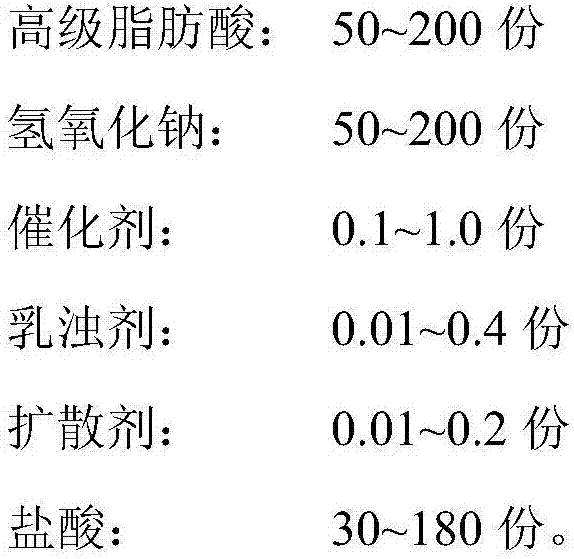

Method used

Image

Examples

Embodiment 1

[0031] Add 115 parts of stearic acid, 120 parts of sodium hydroxide, and 0.5 parts of absolute ethanol into the flask, heat and stir evenly, control the heating temperature to 70°C, and the reaction time is 7h;

[0032] Add saturated sodium chloride to precipitate sodium stearate, raise the temperature to 85°C, add 0.08 parts of aliphatic amine polyoxyethylene ether, 0.03 parts of alkylbenzene sulfonate, fully react for 1 hour, and then cool to room temperature;

[0033] Add 50 parts of hydrochloric acid to neutralize until the pH is 6.7, and filter to separate and remove impurities to obtain an emulsion, which is the liquid expansion agent.

Embodiment 2

[0035] Add 96 parts of oleic acid, 105 parts of sodium hydroxide, 0.2 parts of absolute ethanol, and 0.1 part of ethylene glycol into the flask, heat and stir evenly, control the heating temperature to 65°C, and the reaction time to 6.5h;

[0036] Add saturated sodium chloride to precipitate sodium stearate, raise the temperature to 90°C, add 0.05 parts of alkylphenol polyoxyethylene ether and 0.04 parts of fatty alcohol polyoxyethylene ether, 0.02 parts of alkylbenzene sulfonate and 0.03 parts The alkylnaphthalene sulfonate, fully reacted for 1.5h and then cooled to room temperature;

[0037] Add 45 parts of hydrochloric acid to neutralize until the pH is 6.9, and filter to separate and remove impurities to obtain an emulsion, which is the liquid expansion agent.

Embodiment 3

[0039] Add 85 parts of oleic acid and 35 parts of linoleic acid, 130 parts of sodium hydroxide, 0.5 parts of ethylene glycol and 0.3 parts of propylene glycol into the flask, heat and stir evenly, control the heating temperature to 70°C, and the reaction time is 7h ;

[0040] Add saturated sodium chloride to precipitate sodium stearate, raise the temperature to 85°C, add 0.03 parts of alkylphenol polyoxyethylene ether and 0.06 part of phenethylphenol polyoxyethylene ether, 0.05 part of alkyl sulfonate and 0.04 Parts of alkyl phosphate, fully reacted for 2h and then cooled to room temperature;

[0041] Add 70 parts of hydrochloric acid for neutralization until the pH is 6.8, and filter to separate and remove impurities to obtain an emulsion that is the liquid expansion agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com