Warm-rolling working roll and control method of internal and external temperature field

A control method and technology of work rolls, applied in temperature control, rolls, metal rolling, etc., can solve problems such as small stress, and achieve the effect of ensuring the mechanical properties of the rolls and ensuring the mechanical properties required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

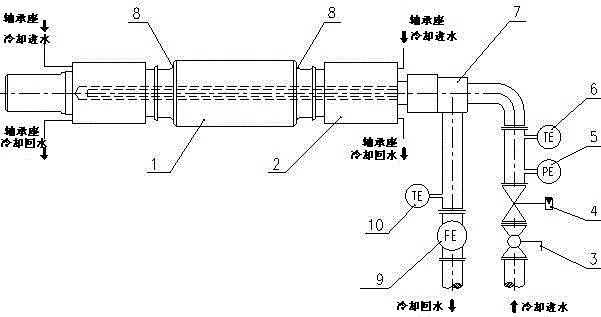

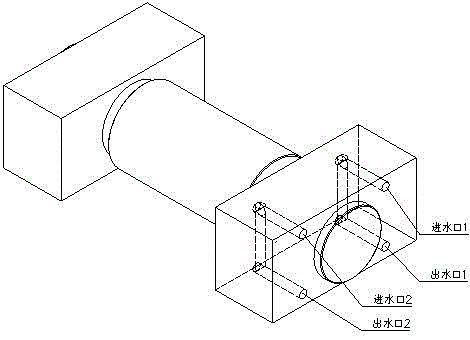

[0086] see image 3 , the torsional section modulus or the bending torsional section modulus of the warm-rolled work roll is taken according to 99% of the solid warm-rolled work roll, so as to determine the perforation diameter of the warm-rolled work roll. according to figure 1 or figure 2 Equipped with corresponding cooling water inlet pipelines, return water pipelines, valves, monitoring instruments and rotary joints, and equipped with corresponding intelligent control units and PLC control systems;

[0087] A method for controlling the internal and external temperature field of a warm rolling work roll chock,

[0088] The general principle is: the heating temperature of the roll surface required by the process must be satisfied, the cooling water flow rate cannot be too large, so as not to exceed the heating capacity of the roll heating device 11, and the flow adjustment method is based on the premise of not affecting the predetermined temperature of the roll surface;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com