Novel biological pollution-resistant polyamide reverse osmosis composite membrane and preparation method thereof

A reverse osmosis composite membrane and anti-biological pollution technology, which is applied in the field of membrane separation, can solve the problems of uncontrollable polymerization process of ordinary free radical polymerization, and achieve the goal of solving uncontrollable polymerization process, improving use efficiency and service life, and saving energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

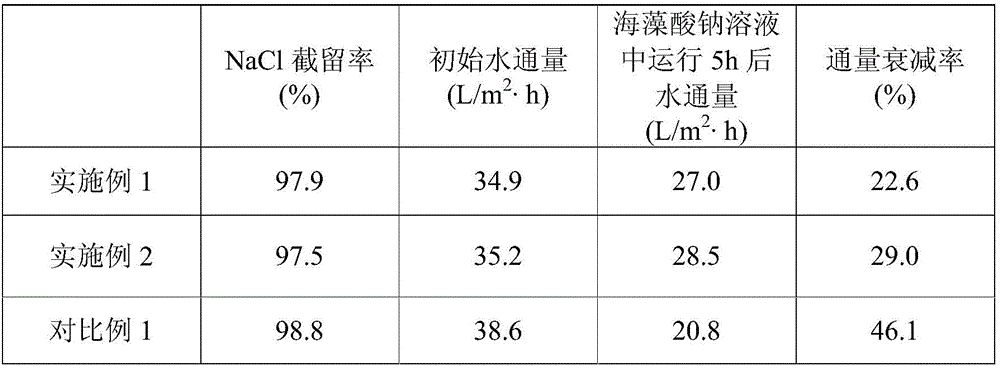

Examples

Embodiment 1

[0041] A preparation method of a novel anti-biological fouling polyamide reverse osmosis composite membrane, comprising the following steps:

[0042] (1) Polyamide reverse osmosis membrane was prepared by interfacial polymerization: first soak the polysulfone-based membrane with 30% isopropanol aqueous solution for 6 hours, then repeatedly rinse the surface of the membrane with deionized water, and let it dry naturally. Preparation mass concentration is 2.0% m-phenylenediamine, 1.6% triethylamine and 4% camphorsulfonic acid aqueous solution, pours above-mentioned aqueous solution into membrane frame, is placed on the shaking table that rotating speed is 80rpm / min 40s, the solution After pouring out, let it dry naturally; prepare a solution of 1,3,5-benzenetricarboxylic acid chloride Isopar G with a mass concentration of 0.1%, pour it into the film frame, let it stand for 30 seconds, and then pour it out. After the Isopar G evaporates to dryness, place it Heat treatment in an o...

Embodiment 2

[0048] A preparation method of a novel anti-biological fouling polyamide reverse osmosis composite membrane, comprising the following steps:

[0049] (1) Polyamide reverse osmosis membrane was prepared by interfacial polymerization: first soak the polysulfone-based membrane with 30% isopropanol aqueous solution for 6 hours, then repeatedly rinse the surface of the membrane with deionized water, and let it dry naturally. Prepare an aqueous solution of m-phenylenediamine, 1.6% triethylamine and 4% camphorsulfonic acid with a mass concentration of 2.0%, pour the above aqueous solution into the membrane frame, shake on a shaker at 80rpm for 40s, pour out the solution and dry it naturally ; prepare 1,3,5-benzenetricarboxylic acid chloride Isopar G solution with a mass concentration of 0.1%, pour it into the film frame, let it stand for 30 seconds, pour it out, and after the Isopar G evaporates to dryness, place it in an oven at 100°C for heat treatment 5min to obtain a cross-linked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com