Spiral-flow type water cap

A swirling, water cap technology, applied in gravity filters, loose filter material filters, filtration and separation, etc., can solve the problem of insufficient filtration density and filtration depth of filter materials, reduce the service life of water caps, and mix backwash water. Insufficient and other problems, to achieve the effect of long service life, reasonable structure and thorough backwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below using the accompanying drawings and examples.

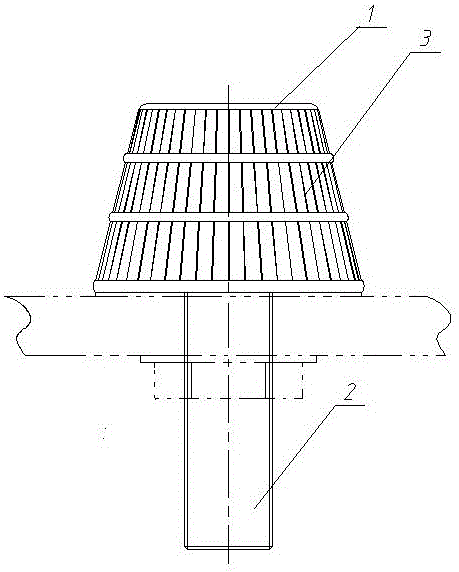

[0018] refer to Figure 1-Figure 4 , a kind of swirling water cap of the present invention, comprises conical water cap body 1, is provided with several nozzles 3 vertically inclined on conical water cap body 1, is provided with center in conical water cap body 1 The water pipe 2 is provided with a water outlet 4 of the central water pipe on the central water pipe 2 located in the conical water cap body 1, and several vertically inclined water ports 3 and the central water pipe form a water swirl channel. The conical water cap body 1 and the central water pipe 2 are integrally formed by using a plastic mold. When using the swirling water cap of the present invention, several swirling water caps are arranged on the filter equipment support plate 6 in several rows, and the interlaced arrangement between rows is adopted for uniform water distribution. Several swirl water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com