Production method for balcony wall-mounted outer space energy water heater

The technology of a space energy water heater and production method is applied in the direction of solar heat collectors, solar thermal energy, and solar heat collectors using working fluids, etc., which can solve the problems of heat energy waste, high material cost, and bulky heat collectors, etc., and achieve improved Flow range, improved heat transfer effect, simple and standardized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

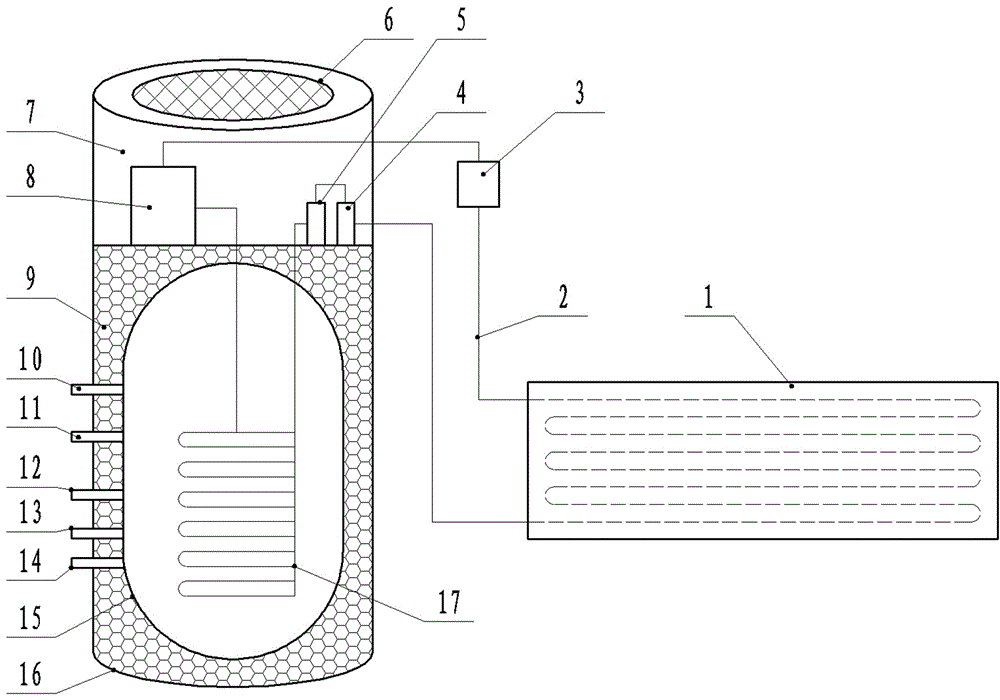

[0029] In order to introduce the present invention in more detail, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0030] As shown in the figure: the production method of the balcony wall-mounted space energy water heater of the present invention comprises the following process steps:

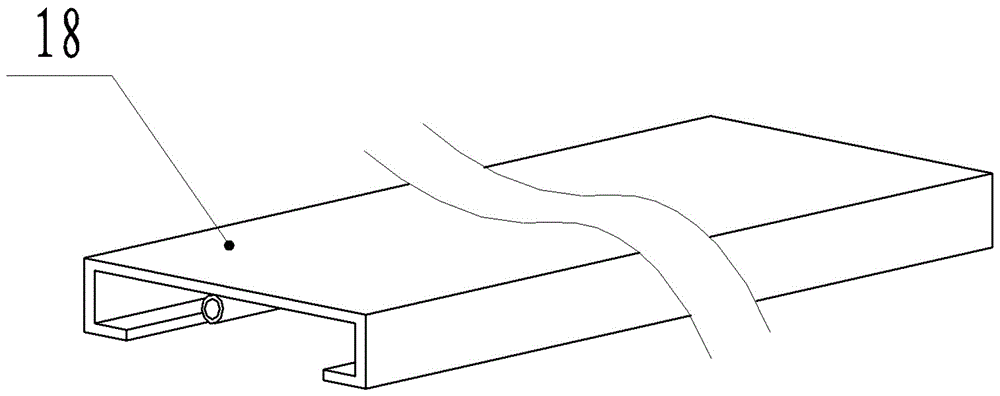

[0031] (1) Prepare the aluminum alloy heat-absorbing guide sheet 18 , heat the aluminum alloy profile to 480-530° C., and extrude the aluminum alloy heat-absorbing guide sheet 18 into one piece by mold extrusion.

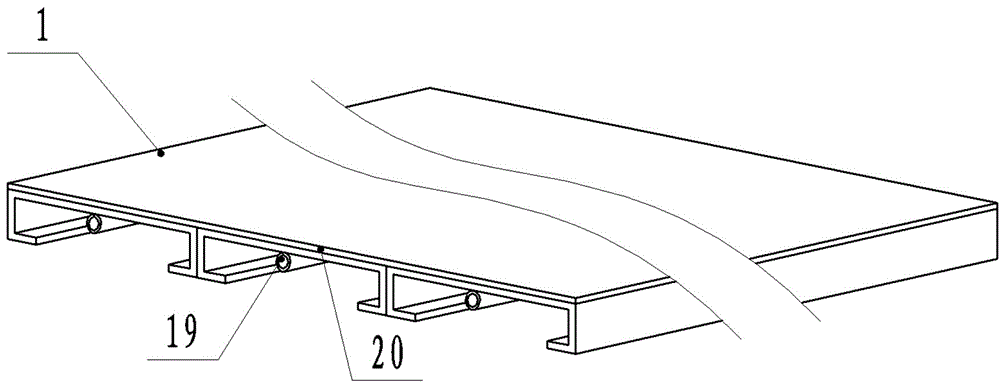

[0032] (2) Cut the aluminum alloy heat-absorbing guide sheet 18 according to the required size, combine and splice the cut pieces of aluminum alloy heat-absorbing guide sheet 18, and then connect the medium conduction tube 19 on the aluminum alloy heat-absorbing guide sheet 18 Utilize aluminum alloy pipe 22 to weld and connect in series.

[0033] (3) Coat the outer surface of the aluminum alloy heat-absorbing gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com