An interaxial finger seal

A sealing device, fingertip sealing technology, applied in the direction of preventing leakage, engine components, machines/engines, etc., can solve the problems of no major changes in the main structure, high manufacturing cost of brush seals, and reduced number of parts, etc. Contact stiffness and adaptability, improved seal tightness and wear resistance, the effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

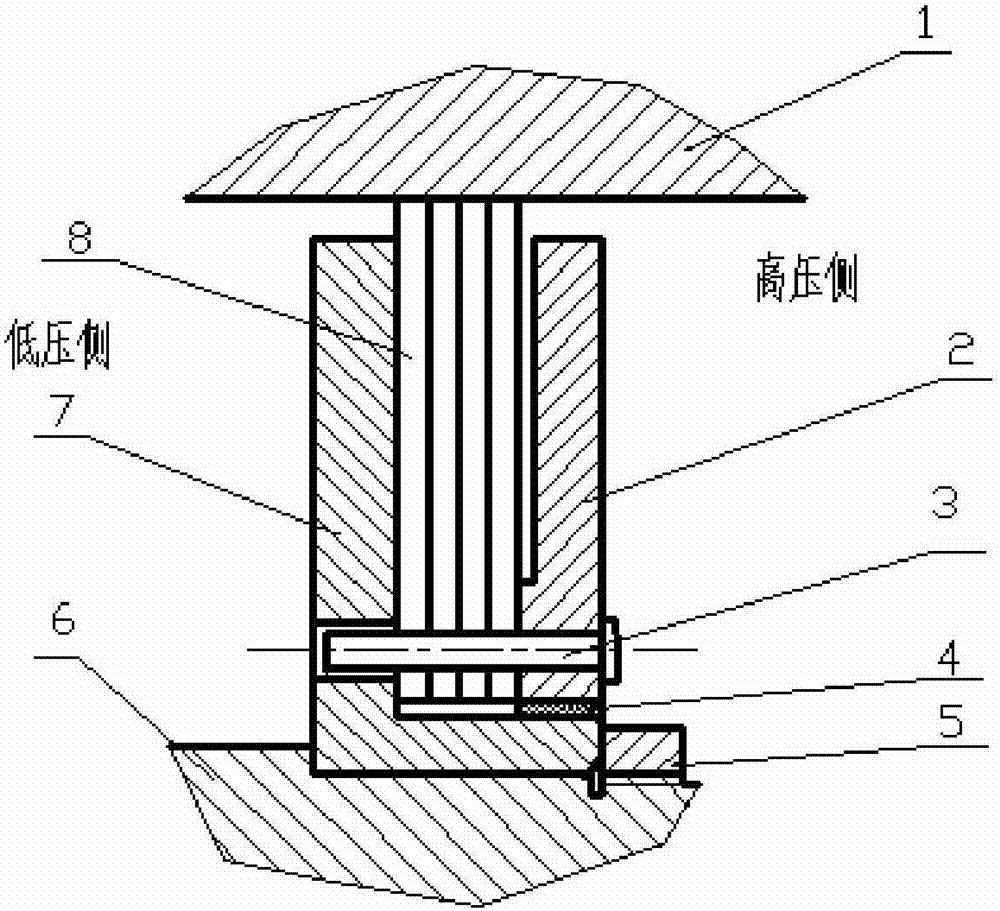

[0028] This embodiment is an inter-shaft finger seal device.

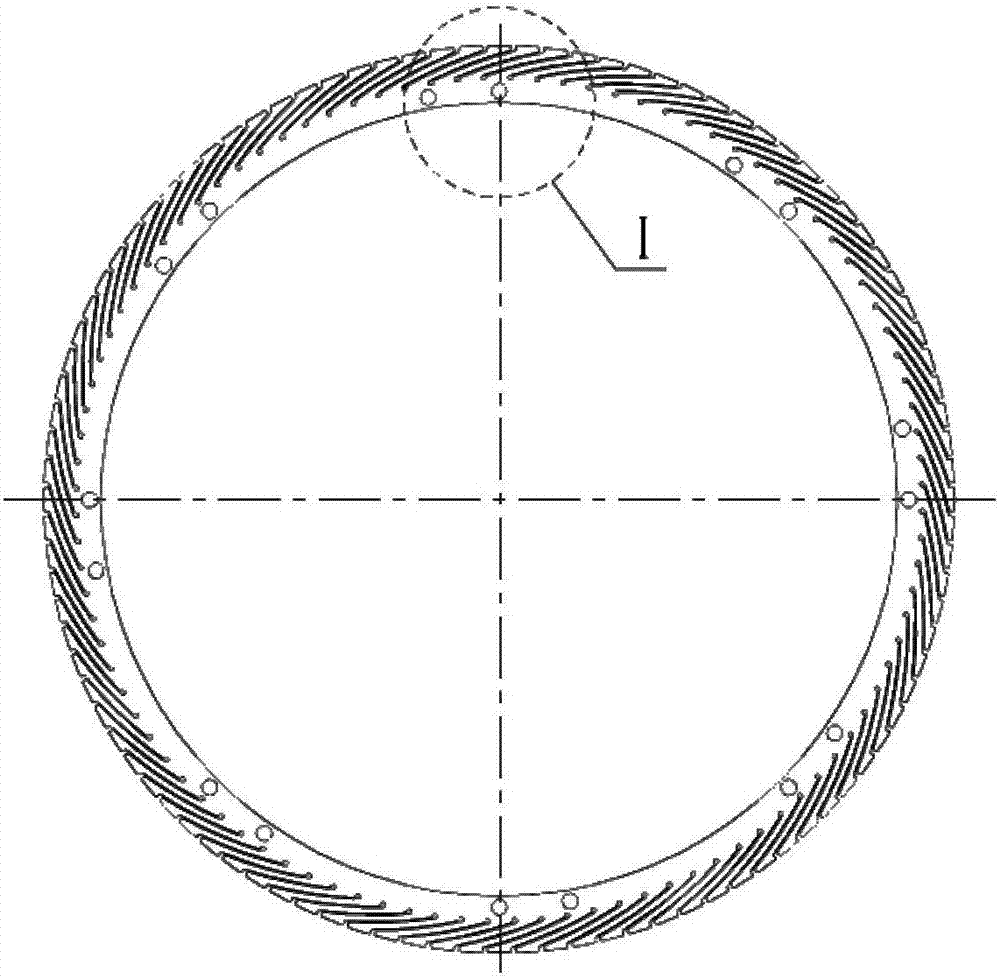

[0029] refer to Figure 1 to Figure 6 , The inter-shaft finger seal device is composed of an outwardly extending inter-shaft finger seal structure installed on the inner shaft and an inwardly extending inter-shaft finger seal structure installed on the outer shaft.

[0030]In this embodiment, the overhanging inter-shaft finger seal structure includes an overhanging front baffle 2, an overhanging elastic element 4, an overhanging rear baffle 7, an overhanging fingertip sealing sheet 8, a fingertip curved beam 14, and a fingertip Boots 15, assembling holes 16 of the overhanging rear baffle, and a plurality of overhanging fingertip sealing sheets 8, and each overhanging fingertip sealing sheet 8 is processed with several fingertip curved beams 14 and fingertip boots 15 along the outer diameter circumferential direction , there are many pairs of assembly holes along the inner diameter circumference; the overhanging fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com