Power island arrangement structure of one-on-one multi-shaft gas turbine extraction condensing back-pressure turbine combined cycle power plant

A back pressure unit and combined cycle technology, which is applied in the direction of combined combustion mitigation and industrial buildings, can solve problems such as additional consideration of environmental protection requirements, and achieve the effect of saving the space of the steam engine room, reducing the overall engineering amount, and facilitating compact layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

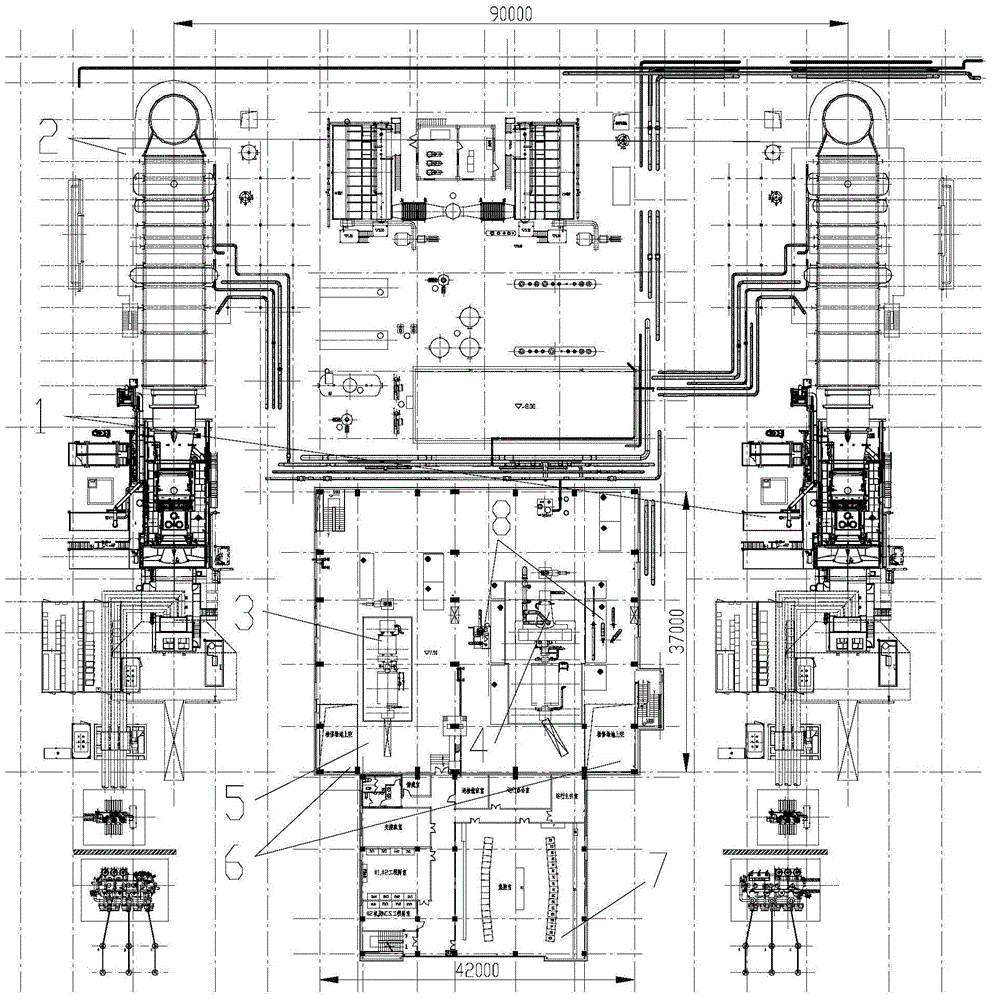

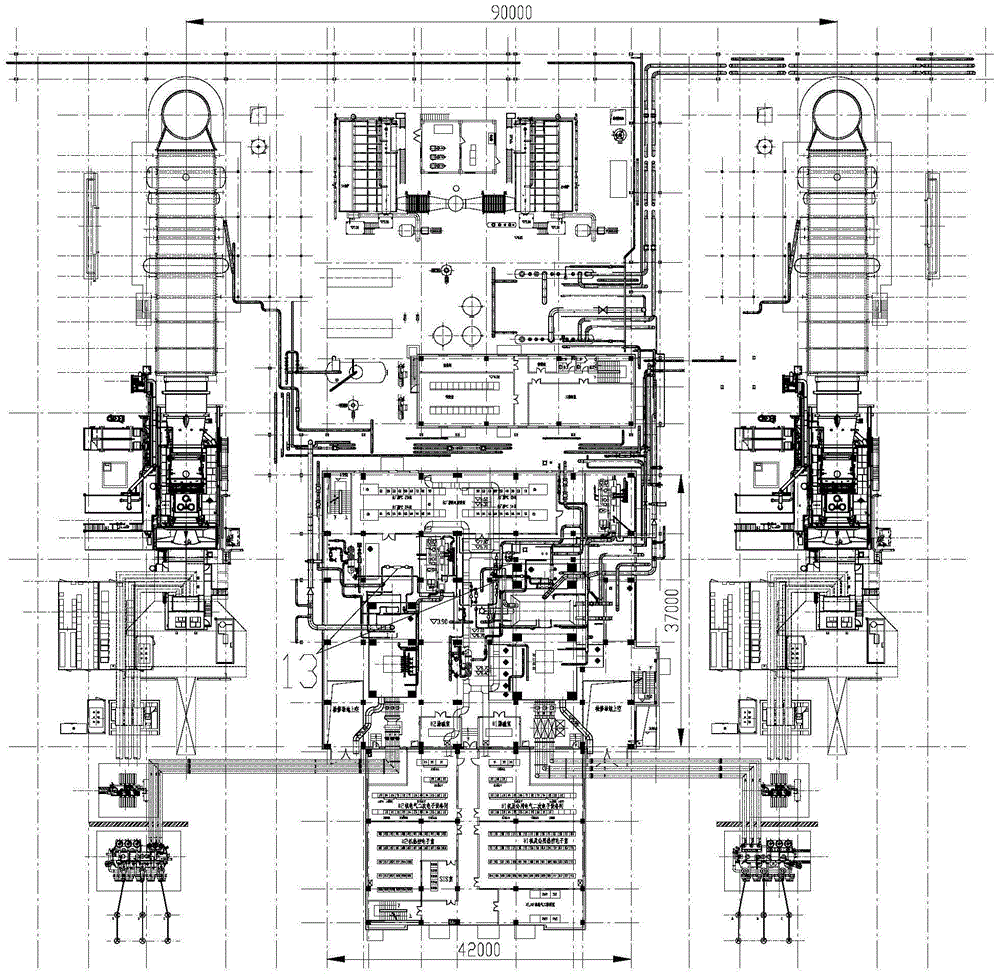

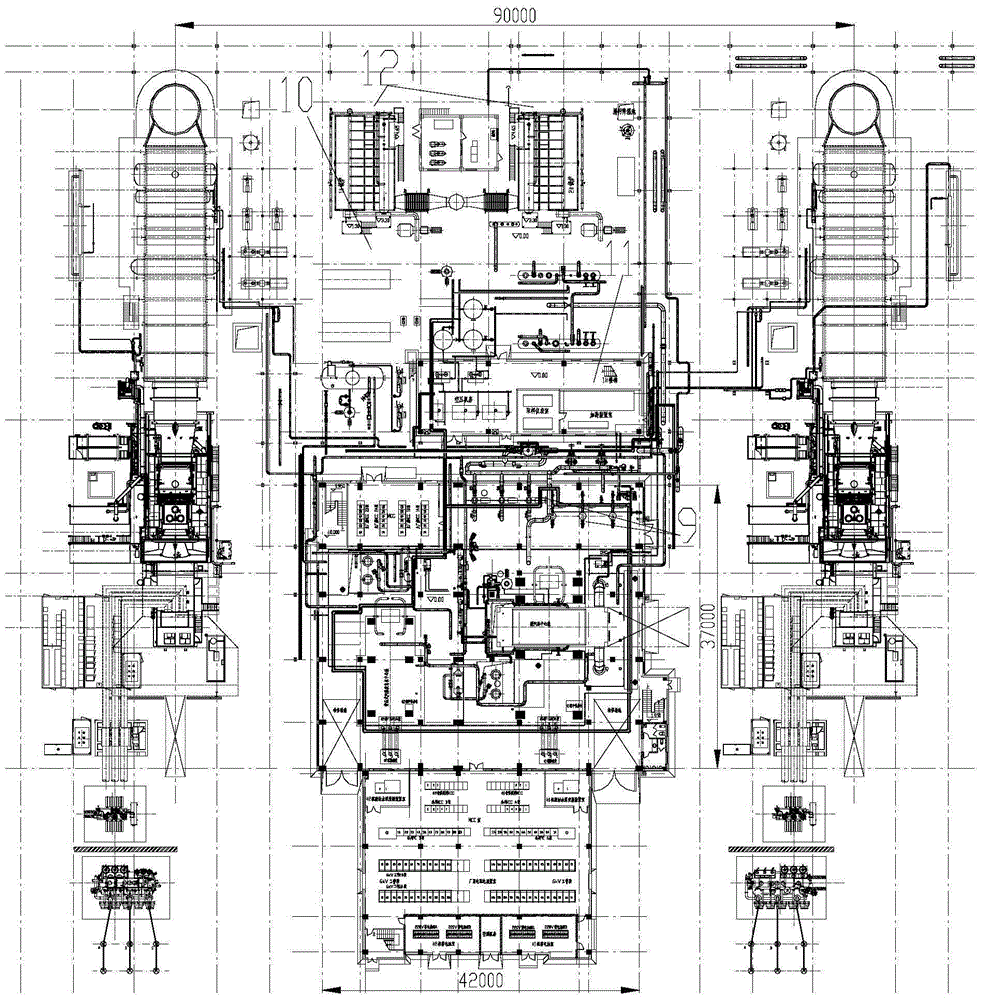

[0024] Embodiment: A "one drag one" multi-shaft gas turbine-extraction condensate back pressure unit combined cycle power island layout structure, the "one drag one" multi-shaft gas turbine-extraction condensate back pressure unit The combined cycle power plant mainly includes gas turbines, waste heat boilers and steam turbines. The two gas turbines are arranged in a row in the open air, and the two waste heat boilers are arranged in mirror-image symmetry. The above-mentioned steam turbine house adopts unequal column spacing joint workshop, and the column spacing of the side workshop of the back pressure unit is 5 meters, 8 meters, and 5 meters; The compressor unit and the extraction unit are provided with independent inspection holes of 4.91×9 meters and 6.15×9 meters respectively, and two cranes of 32t / 5t and 75t / 20t are equipped correspondingly. The MCCs are respectively arranged on the 0-meter floor and the middle floor, and the generator outlets are located on the 3.9-met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com