Rigid combined steel bridge deck pavement structure

A technology of steel bridge deck and steel bridge deck, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of fatigue cracks, easy cracks, delamination, rutting, structural safety and durability hazards of steel bridge decks. , to achieve the effect of improving fatigue problems, improving structural fatigue, and improving overall stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

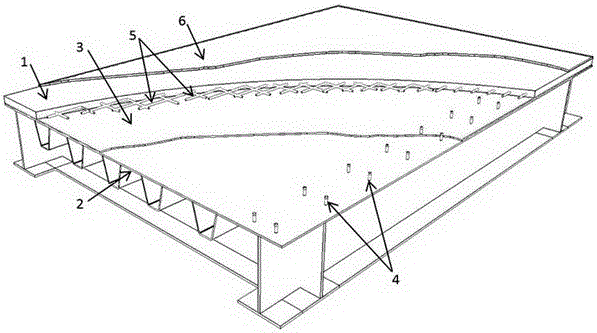

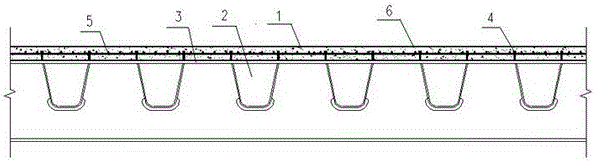

[0018] Such as figure 1 , figure 2 As shown, the present invention provides a rigid composite steel bridge deck pavement structure, which mainly includes a high-strength and toughness concrete pavement layer 1 and an orthotropic steel bridge deck 2 .

[0019] Wherein, the high-strength and toughness concrete pavement 1 and the orthotropic steel bridge deck 2 are combined by epoxy adhesive 3 and / or shear connectors 4 into a whole to bear force together. The thickness of the high-strength and toughness concrete pavement layer 1 ranges from 5 to 10 cm. The high-strength and toughness concrete used is conventionally maintained on-site low-shrinkage concrete, which has high crack resistance, is convenient for construction, and has low maintenance costs. The high-strength and toughness concrete is steel fiber concrete, and steel fibers are evenly distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com