Sheared sheepskin product with dry-milled glaze

A technology for sheep shearing and products, applied in the field of sheep shearing, can solve the problems of no natural texture on the smooth surface, no leather layer, limited market scope, etc., to expand the style and sales market, excellent waterproof performance, and uniform pile. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

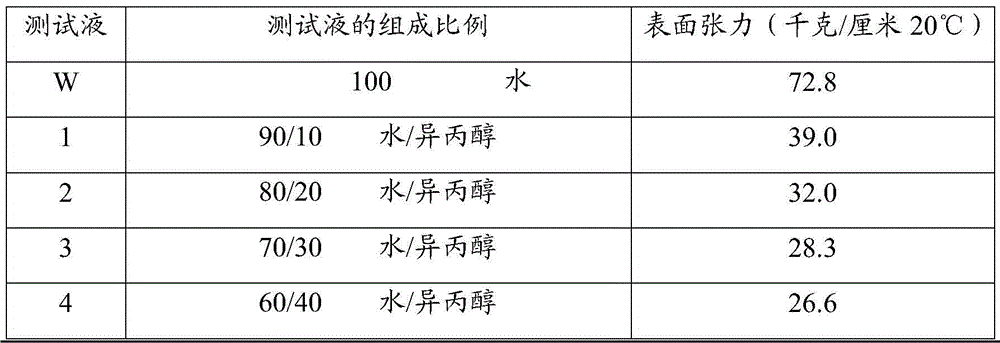

[0061] Carry out dry stretch board treatment to the sheep shearlings to be treated with no spots on the board surface and complete skin shape to obtain the sheep shearlings treated by dry stretch boards; mix 10kgWR-321 and 160kg butyl acetate to obtain the first mixed solution, and Described first mixed solution carries out back cover to the smooth surface of the sheep shearling that dry stretch board handles, and the gun lattice of the spraying machine that adopts when back cover is 12, and the pressure during back cover is 1.3MPa, and line skin 9 meters, every square meter Contain about 250g of the first mixed solution, then dry at 90°C, hang the dried sheep shearling at 20°C for 12 hours, and obtain the back-covered sheep shearling;

[0062] The present invention carries out the waterproof performance test to the sheep shearling with the back cover obtained according to the above-mentioned technical scheme, and the test result is grade 4;

[0063] Mix 3kgLD-5959, 6kgLD-5928...

Embodiment 2

[0071] Carry out dry stretch board treatment to the sheared sheep wool to be treated with no spots on the board surface and complete skin shape to obtain the sheep sheared wool treated by dry stretch board; 12kgWR-321 and 150kg butyl acetate are mixed to obtain the first mixed solution, and Described first mixed solution carries out back cover to the smooth surface of the sheep shearling that dry stretch board handles, and the gun grid of the spraying machine that adopts when back cover is 12, and the pressure during back cover is 1.2MPa, and line skin 9 meters, every square meter Contain about 250g of the first mixed solution, then dry at 90°C, hang the dried sheep shearling at 20°C for 15 hours, and obtain the back-covered sheep shearling;

[0072] The present invention carries out the waterproof performance test to the sheep shearling with the back cover obtained according to the above-mentioned technical scheme, and the test result is 3.5 grades;

[0073] Mix 2kgLD-5959, 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com