Method for enzymatically synthesizing medium-long chain structure triglyceride

A technology for structural triglycerides and long-chain triglycerides, which is applied in the field of enzymatic synthesis of medium and long-chain structural triglycerides, can solve the problems of high price of fatty acids and increase the difficulty of cost separation and operation, and achieves a simple process and is convenient for large-scale operations. The effect of industrialization promotion and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

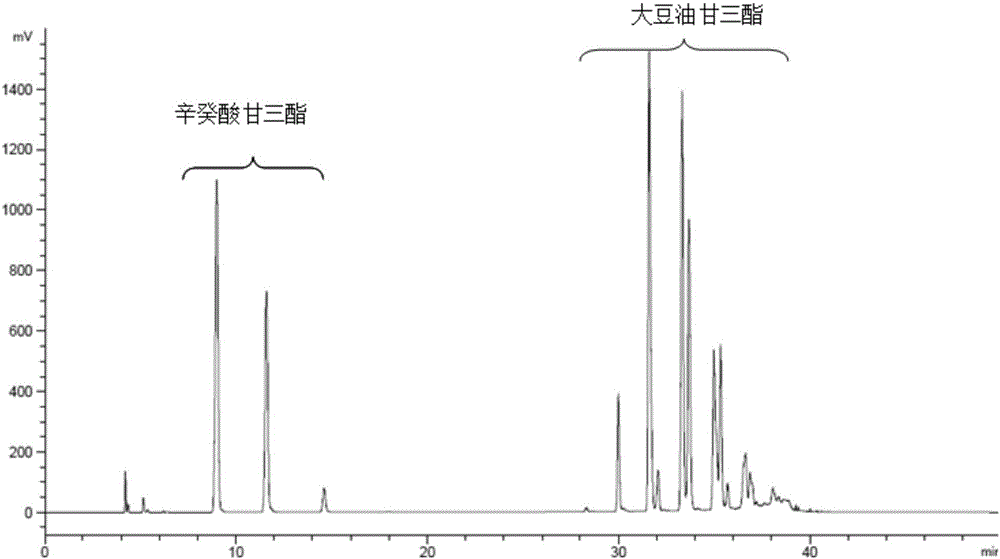

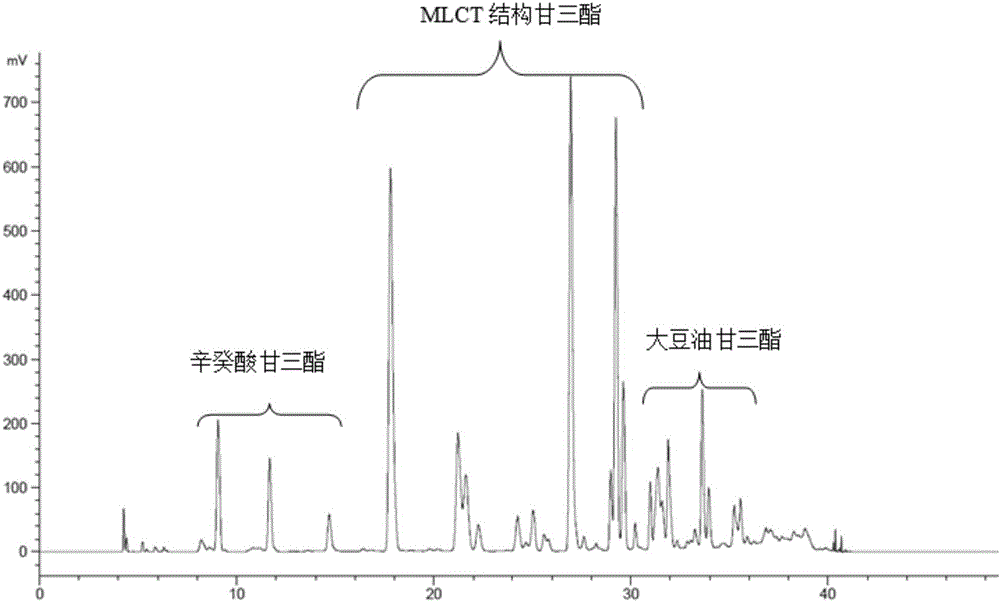

Embodiment 1

[0034] The batch enzyme reaction is carried out in a batch-type stirred tank reactor. The mass ratio of soybean oil and caprylic triglyceride is 6:4. In a solvent-free system, 8% immobilized lipase Lipozyme435 is added, and the pressure is 85°C Under stirring reaction 3h, stirring speed is 400r / min, after the reaction finishes, centrifuge 10min under the condition of 4000r / min to remove lipase, obtain medium and long chain structure triglyceride, through HPLC analysis, the content of medium and long chain structure triglyceride reaches 82.26%.

Embodiment 2

[0036] The batch enzyme reaction is carried out in a batch-type stirred tank reactor. The mass ratio of rapeseed oil and caprylic triglyceride is 1:1. In a solvent-free system, 5% immobilized lipase Novozym435 is added, under normal pressure Stir and react at 80°C for 4 hours at a stirring speed of 300r / min. After the reaction, centrifuge at 4000r / min for 10min to remove lipase and obtain medium-long-chain triglycerides. After HPLC analysis, the medium-long-chain structure triglycerides The content reaches 73.26%.

Embodiment 3

[0038] The batch enzyme reaction is carried out in a batch-type stirred tank reactor. The mass ratio of fish oil and caprylic triglyceride is 1:2. In a solvent-free system, add 10% immobilized lipase NS40086 and stir at 60°C under normal pressure React for 2 hours, stirring at a speed of 500r / min. After the reaction, centrifuge at 4000r / min for 10 minutes to remove lipase, and obtain medium and long-chain triglycerides. According to HPLC analysis, the content of medium and long-chain triglycerides reaches 65.82%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com