Preparation method of universal super-amphiphobic nano coating based on flower shape titanium dioxide nano particles

A technology of titanium dioxide and nanoparticles, which is applied in the field of preparation of universal superamphiphobic nano-coatings, can solve the problems of weak mechanical strength, strong substrate resistance, single preparation method, etc., and achieve strong adhesion, long service life, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

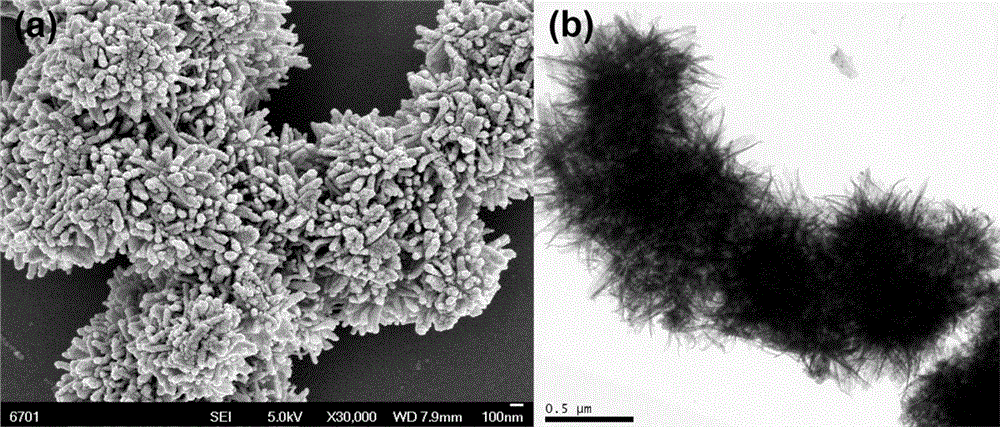

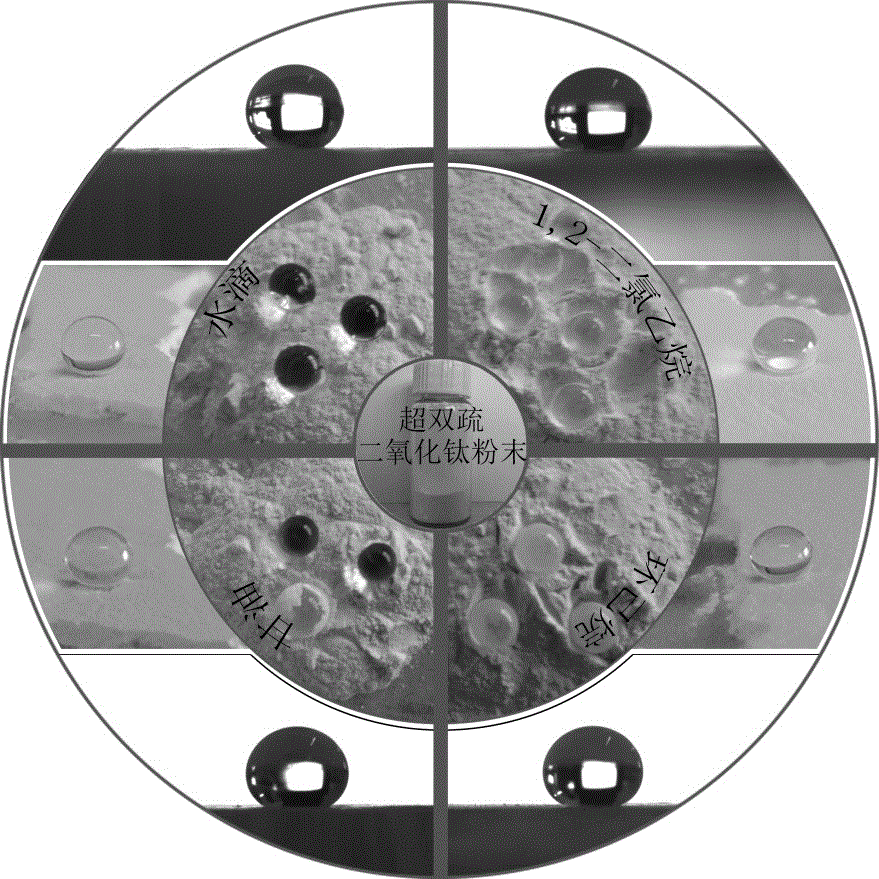

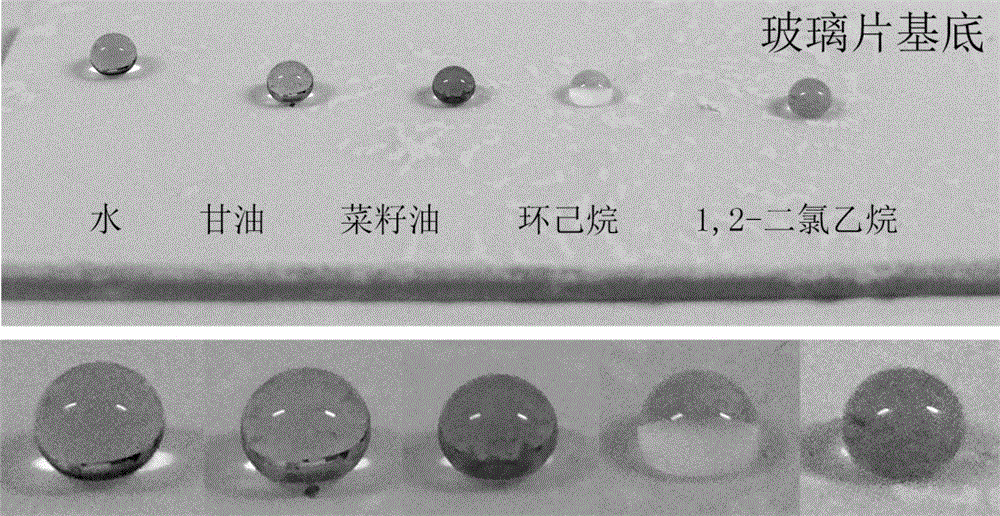

[0031] (1) Preparation of flower-shaped titanium dioxide nanoparticles: Take 2ml of tetrabutyl titanate, add it dropwise to 40ml of a mixed solution of ethanol and glycerol with a volume ratio of 3:1 at room temperature, and continue stirring for 5 minutes to form a transparent mixed solution. Then, the above-mentioned mixed solution was transferred to a reaction kettle, and placed in an environment with a temperature of 180° C. for 24 hours. After the reaction, it was cooled to room temperature, and a white precipitate was obtained by repeated centrifugation and washing with ethanol, and then drying. Finally, the white precipitate was calcined at 450 °C in air for 2 h to obtain a white powdery product, thus completing the preparation of flower-like titanium dioxide nanoparticles.

[0032] (2) Low surface energy modification: Add the titanium dioxide powder product prepared in step (1) to 100ml of 1% perfluorooctanoic acid in n-hexane solution, and disperse it by ultrasonicat...

Embodiment 2

[0035] (1) Preparation of flower-shaped titanium dioxide nanoparticles: Take 2ml of tetrabutyl titanate, add it dropwise to 40ml of a mixed solution of ethanol and glycerol with a volume ratio of 3:1 at room temperature, and continue stirring for 5 minutes to form a transparent mixed solution. Then, the above-mentioned mixed solution was transferred to a reaction kettle, and placed in an environment with a temperature of 180° C. for 24 hours. After the reaction, it was cooled to room temperature, and a white precipitate was obtained by repeated centrifugation and washing with ethanol, and then drying. Finally, the white precipitate was calcined at 450 °C in air for 2 h to obtain a white powdery product, thus completing the preparation of flower-like titanium dioxide nanoparticles.

[0036] (2) Low surface energy modification: Add the titanium dioxide powder product prepared in step (1) to 100ml of 0.5% perfluorooctanoic acid in n-hexane solution, and disperse it by ultrasonic...

Embodiment 3

[0039](1) Preparation of flower-shaped titanium dioxide nanoparticles: Take 2ml of tetrabutyl titanate, add it dropwise to 40ml of a mixed solution of ethanol and glycerol with a volume ratio of 3:1 at room temperature, and continue stirring for 5 minutes to form a transparent mixed solution. Then, the above-mentioned mixed solution was transferred to a reaction kettle, and placed in an environment with a temperature of 180° C. for 24 hours. After the reaction, it was cooled to room temperature, and a white precipitate was obtained by repeated centrifugation and washing with ethanol, and then drying. Finally, the white precipitate was calcined at 450 °C in air for 2 h to obtain a white powdery product, thus completing the preparation of flower-like titanium dioxide nanoparticles.

[0040] (2) Low surface energy modification: Add the titanium dioxide powder product prepared in step (1) to 100ml of 1% perfluorooctanoic acid in n-hexane solution, and disperse it by ultrasonicati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com