High-temperature-resistant light-weight environment-friendly sole material and preparation method thereof

A technology for shoe sole materials and high temperature resistance, which is applied in the field of rubber shoe sole materials, can solve the problems of not being resistant to high temperatures, not being light enough for shoes, not being environmentally friendly enough, and achieves the effect of simple preparation method and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

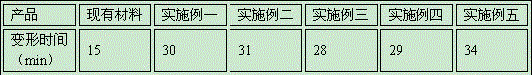

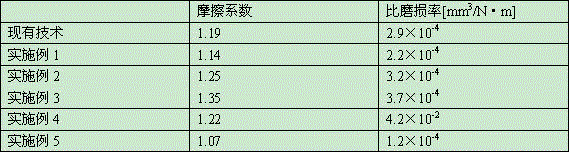

Examples

Embodiment 1

[0021] A kind of high-temperature resistant light-weight environment-friendly sole material that the present invention proposes, comprises the raw material of following weight part: 100 parts of butadiene rubber, 20 parts of polyvinyl chloride, 10 parts of sulfur, 1 part of antioxidant SP, 20 parts of carbon black, styrene- 50 parts of butadiene block copolymer, 1 part of aramid staple fiber, 10 parts of salicylic acid, 12 parts of dimethyl thiodiglycolate, 20 parts of polystyrene microspheres, 7 parts of magnesium hydroxide, flame retardant 1 part, 5 parts of accelerator CZ.

[0022] The present invention also proposes a preparation method of a high-temperature-resistant lightweight environmental-friendly sole material, comprising the following steps:

[0023] S1. Weigh butadiene rubber, polyvinyl chloride, and styrene-butadiene block copolymer according to the weight ratio, mix the above-mentioned raw materials fully first, then put them into an open mill for open milling, a...

Embodiment 2

[0028] A kind of high-temperature-resistant light-weight environment-friendly sole material proposed by the present invention comprises the following raw materials in parts by weight: 105 parts of butadiene rubber, 25 parts of polyvinyl chloride, 11 parts of sulfur, 1.5 parts of anti-aging agent SP, 25 parts of carbon black, benzene 55 parts of ethylene-butadiene block copolymer, 1.5 parts of aramid staple fiber, 11 parts of salicylic acid, 14 parts of dimethyl thiodiglycolate, 21 parts of polystyrene microspheres, 7.5 parts of magnesium hydroxide, barrier 2 parts of fuel, 5.5 parts of accelerator CZ.

[0029] The present invention also proposes a preparation method of a high-temperature-resistant lightweight environmental-friendly sole material, comprising the following steps:

[0030] S1, weigh butadiene rubber, polyvinyl chloride, and styrene-butadiene block copolymer according to the proportioning ratio, fully mix the above-mentioned raw materials first, then put them into...

Embodiment 3

[0035] A kind of high-temperature-resistant light-weight environment-friendly sole material that the present invention proposes, comprises the raw material of following weight part: 110 parts of butadiene rubber, 30 parts of polyvinyl chloride, 12 parts of sulfur, 2 parts of antioxidant SP, 30 parts of carbon black, styrene- 60 parts of butadiene block copolymer, 2 parts of aramid staple fiber, 12 parts of salicylic acid, 16 parts of dimethyl thiodiglycolate, 25 parts of polystyrene microspheres, 8 parts of magnesium hydroxide, flame retardant 3 parts, accelerator CZ6 parts.

[0036] The present invention also proposes a preparation method of a high-temperature-resistant lightweight environmental-friendly sole material, comprising the following steps:

[0037] S1. Weigh butadiene rubber, polyvinyl chloride, and styrene-butadiene block copolymer according to the weight ratio, mix the above-mentioned raw materials fully first, and then put them into an open mill for open kneadin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com